Deep Ocean Exploration | Neutral Buoyancy Cable | Anti-Twist Design | Reinforced Core, Stable Structure

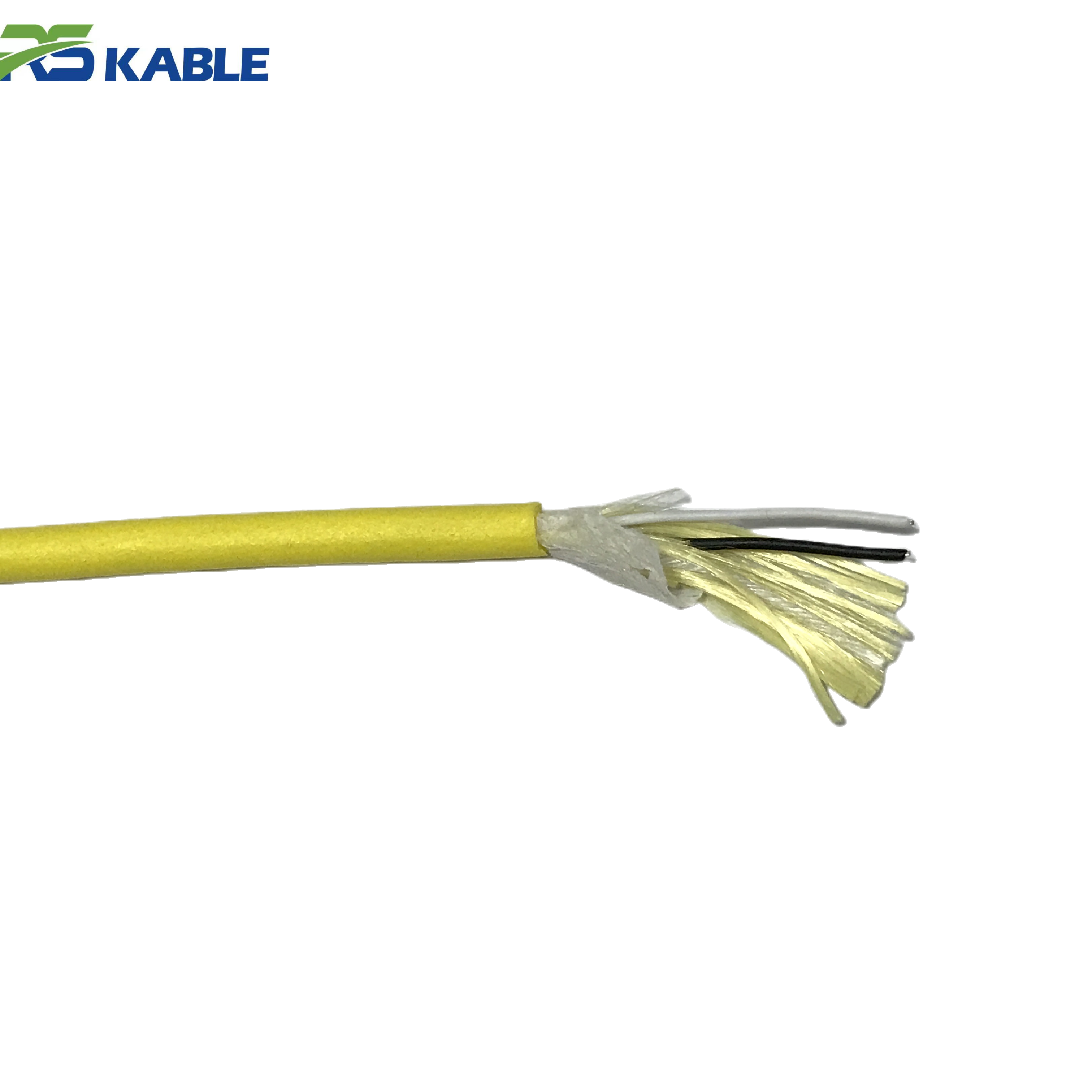

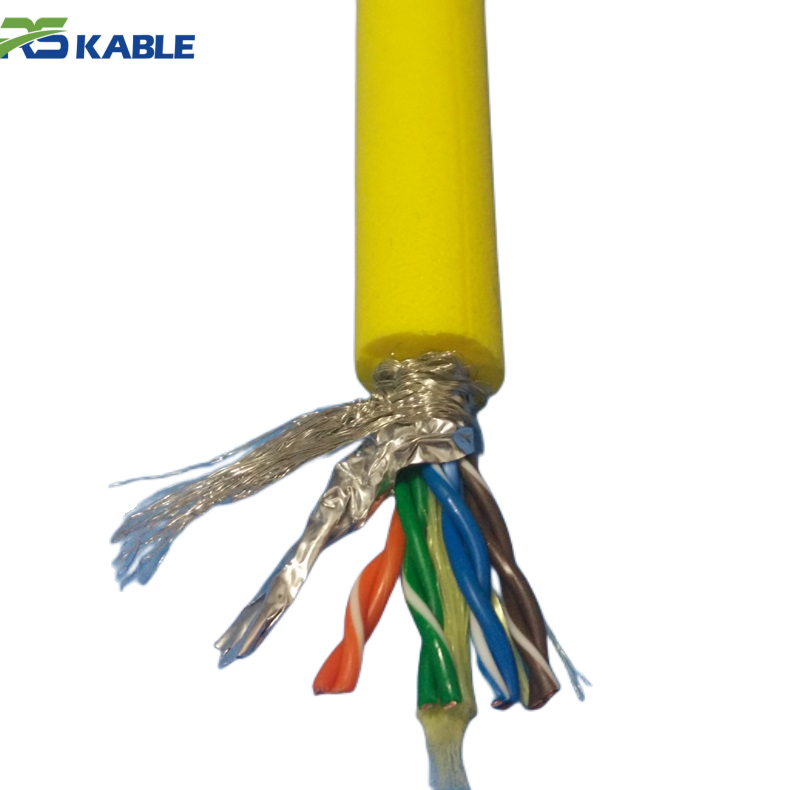

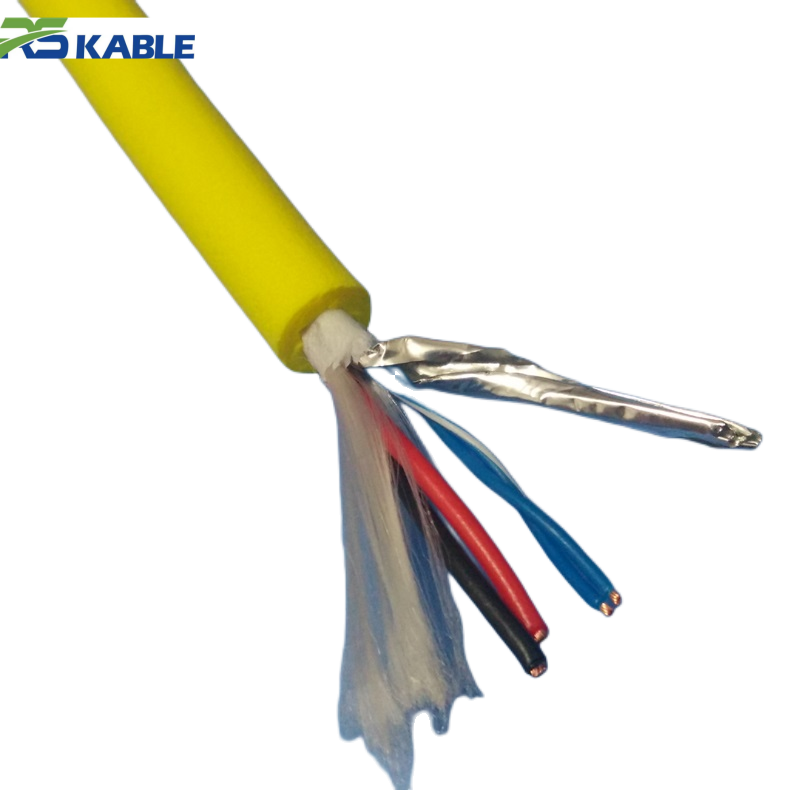

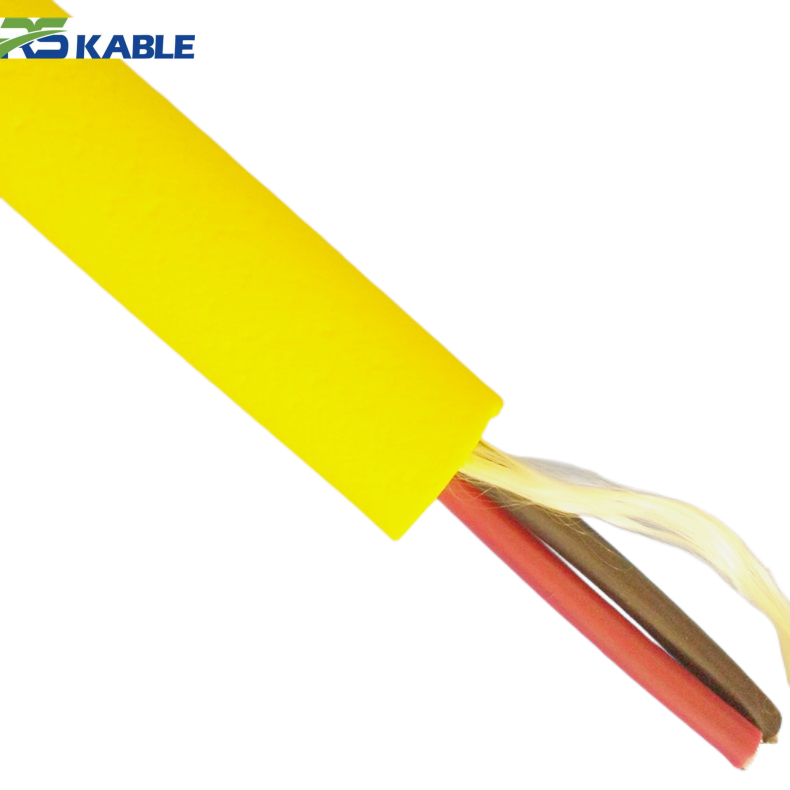

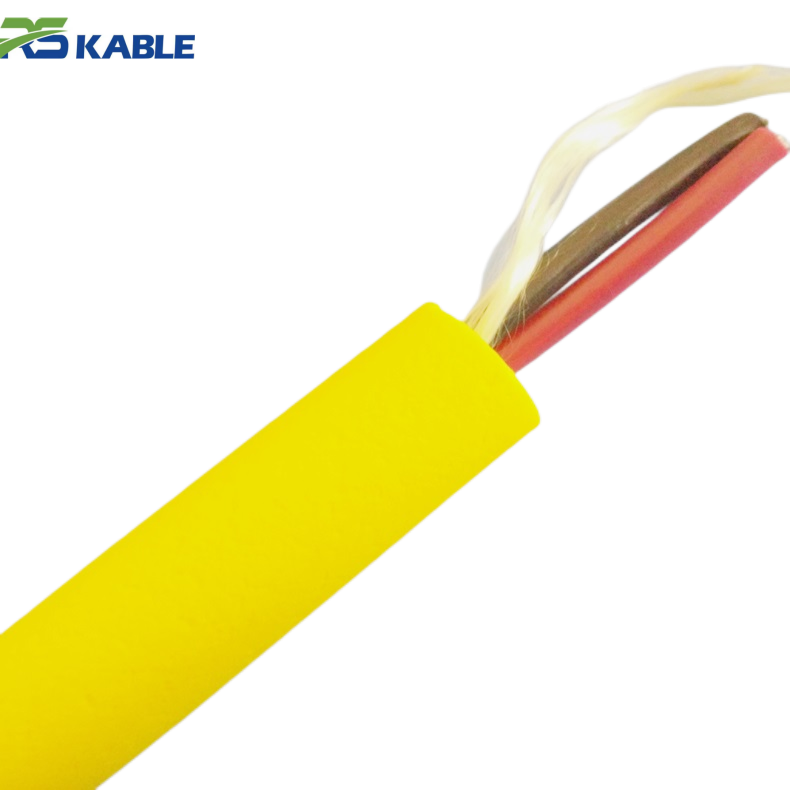

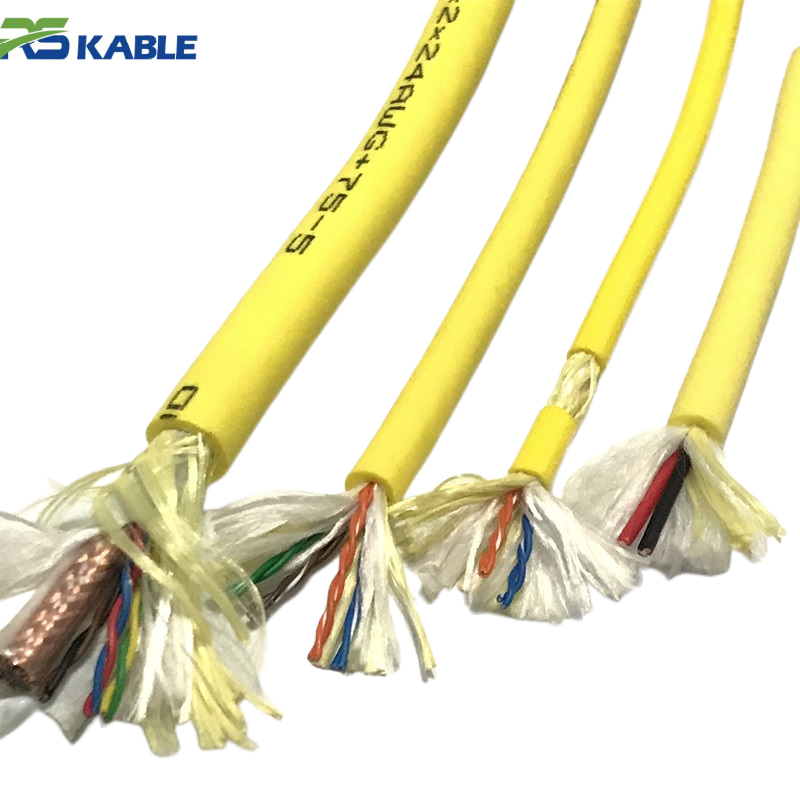

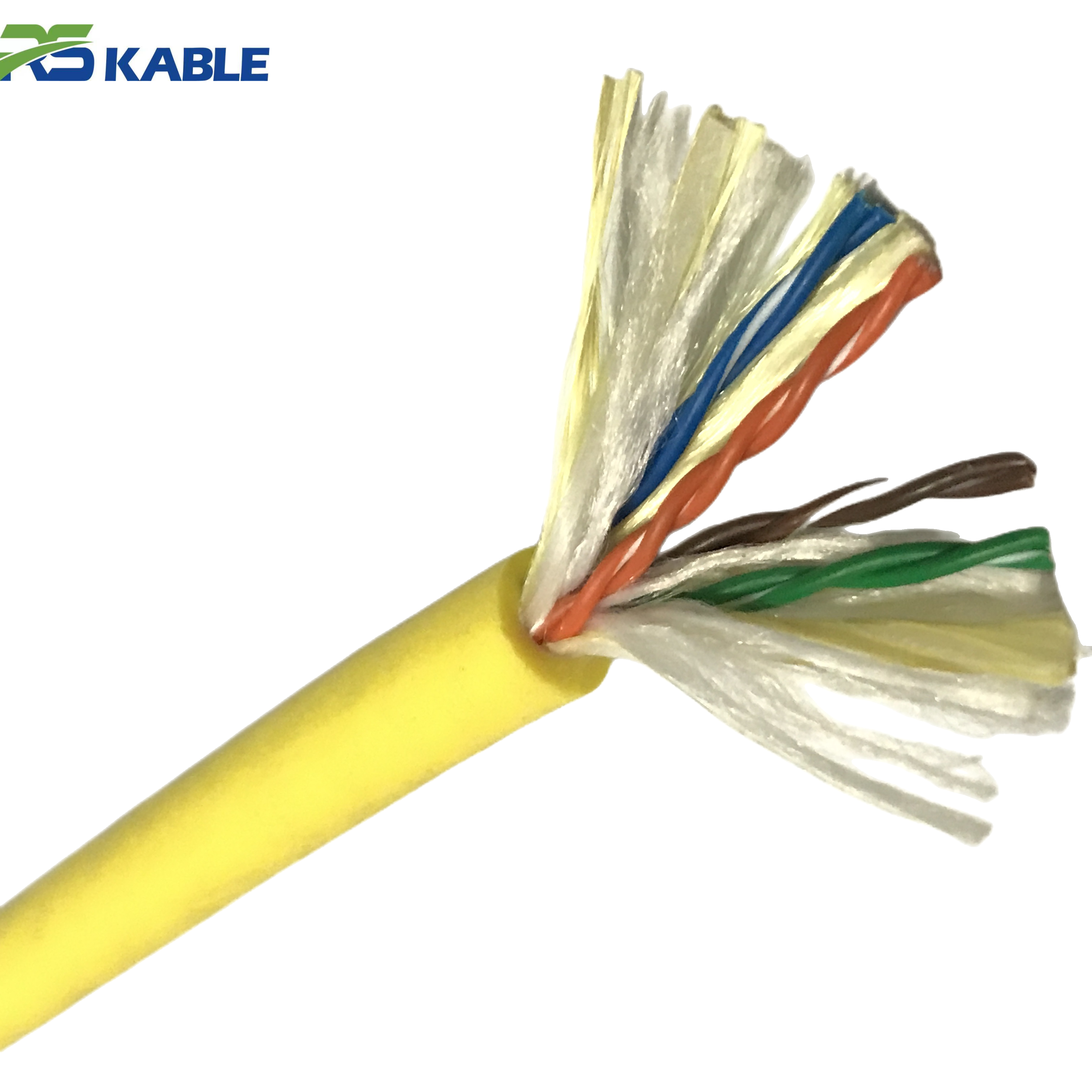

• Conductor: Multi-stranded tinned copper with optimized cross-section and Class 5/6 flexibility for reliable power and signal transmission in extreme subsea environments.

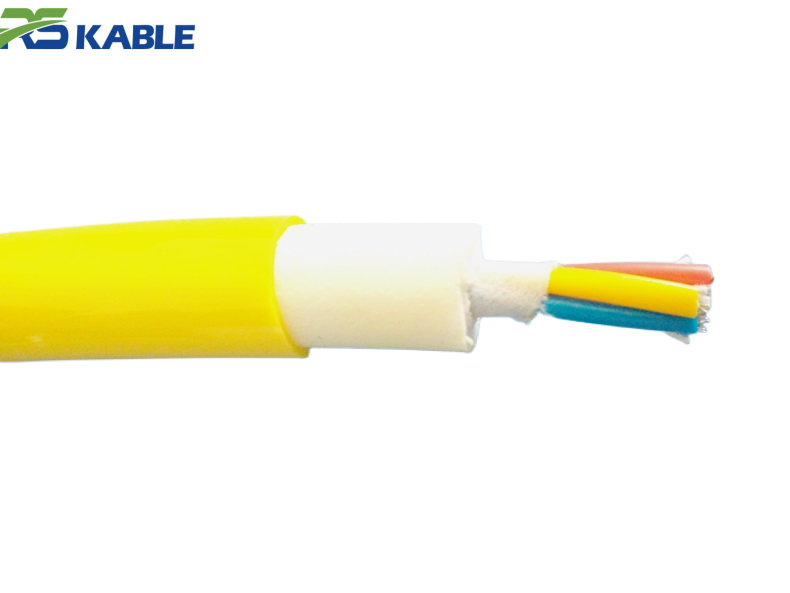

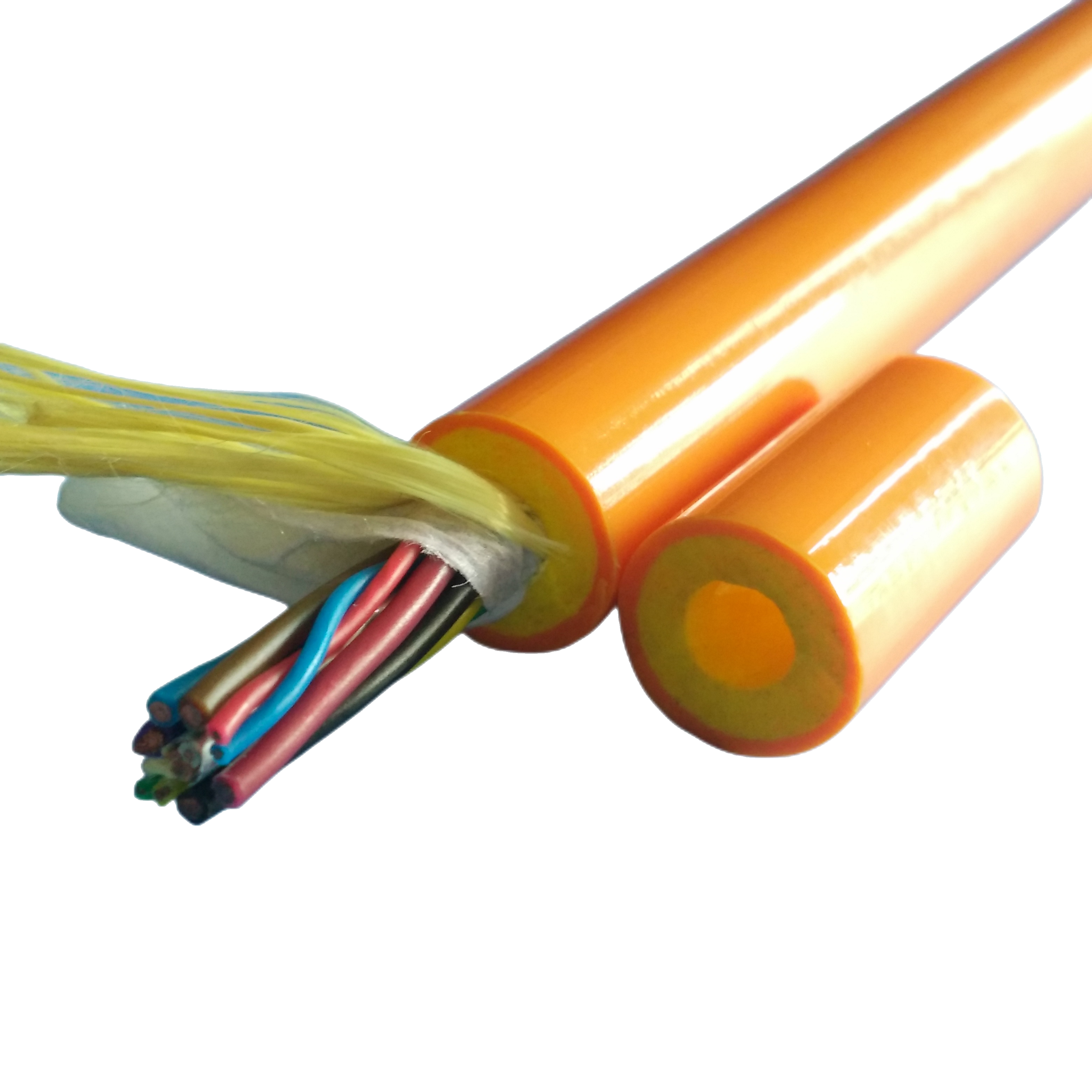

• Jacket: TPU or polyurethane abrasion-resistant outer layer, engineered for seawater, biofouling, and chemical resistance while maintaining low drag and hydrodynamic stability.

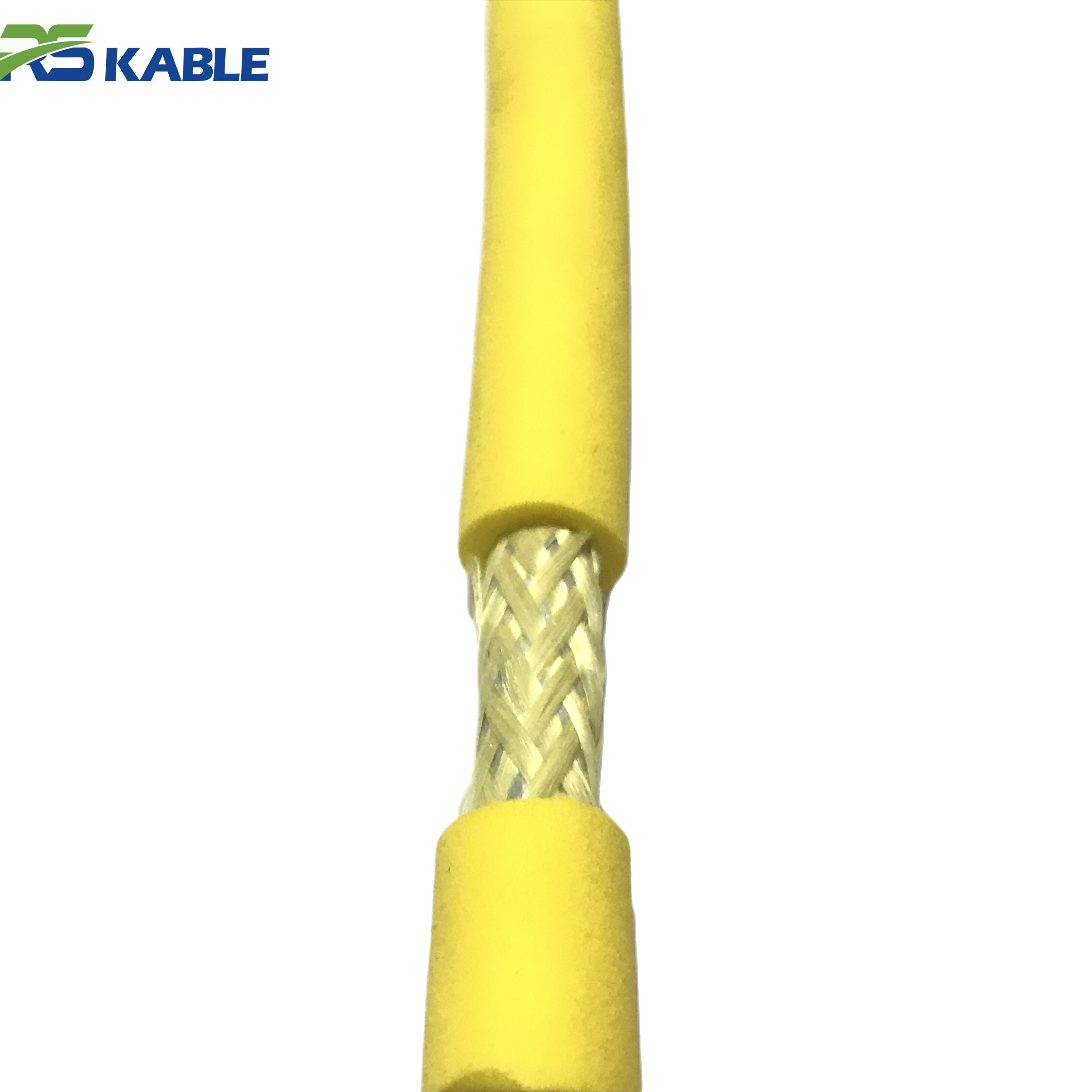

• Structure: Anti-twist helical core with reinforced aramid/Kevlar strength members, precision foamed insulation, and triple-layer shielding for stable neutral buoyancy and mechanical integrity.

• Performance: Exceptional torsional resistance and flexibility, bend radius 5–7×OD, ensuring reliable operation for ROV/AUV missions up to 7,000 meters deep with minimal drag.

• Environment: Fully optimized for deep ocean exploration, supporting variable salinity, temperatures –40°C to +75°C, and long-term deployments in extreme subsea conditions.

Deep Ocean Exploration | Neutral Buoyancy Cable | Anti-Twist Design | Reinforced Core, Stable Structure

Maximize the performance of your deep ocean missions with our engineered Neutral Buoyancy Cable. Designed for extreme subsea exploration, this cable features an anti-twist construction, reinforced core, and precisely calibrated buoyancy for stable handling and reliable power, control, and data transmission. Ideal for ROVs, AUVs, and manned submersibles operating at great depths.

Produced under ISO 9001:2015 certification, fully RoHS and REACH compliant, and verified by ABS/DNV where required, our solutions are trusted by scientific, commercial, and defense operators worldwide.

Why Choose Our Neutral Buoyancy Cable for Deep Ocean Missions?

Operating in the deep ocean presents unique challenges: cable twisting, tension variations, and drag can impact vehicle stability and mission outcomes. Our Neutral Buoyancy Cable is engineered to address these challenges with:

-

Anti-twist core design to prevent rotational stress on ROV/AUV tethers

-

Reinforced aramid/Kevlar strength members for enhanced mechanical stability

-

Precisely neutral buoyancy to reduce vertical forces and energy consumption

-

Durable outer jacket resistant to abrasion, biofouling, and saltwater corrosion

-

Optimized for dynamic deployments, ensuring signal integrity and safe operations in complex underwater environments

Product Models and Core Attributes

| Model | Core Attributes | Conductor / Fiber Configuration | Rated Depth | Outer Diameter | Buoyancy Control |

|---|---|---|---|---|---|

| NB-DOE-4P | 4 power cores, anti-twist, reinforced | 4 × 2.0 mm² tinned copper | 5,000 m | 18.5 mm | Neutral (~0 kg/m) |

| NB-DOE-6H | 6-core hybrid, shielded, high-strength | 4 × 1.5 mm² + 2 × coax/fiber hybrid | 6,000 m | 21.0 mm | Neutral (~0 kg/m) |

| NB-DOE-4FO | 4 power + fiber optic, low-drag jacket | 2 × 2.0 mm² + 2–4 fiber elements | 6,500 m | 22.8 mm | Neutral (~0 kg/m) |

| NB-DOE-HD | Heavy-duty reinforced, triple-shield | 6 × 2.5 mm² + multi-pair + fiber | 7,000 m | 26.0 mm | Neutral (~0 kg/m) |

All models use seawater-resistant TPU or polyurethane jackets, multi-layer shielding for EMI reduction, and aramid strength members for superior tensile and torsional stability.

Applications and Use Cases

Our Neutral Buoyancy Cable supports a wide range of deep ocean operations, including:

-

Deep ocean scientific research and seabed mapping

-

Hydrothermal vent and biodiversity exploration

-

Subsea pipeline and cable inspection

-

Long-duration AUV/ROV missions in extreme depths

-

Military and defense submersible operations

-

Subsea mining and resource surveys

Long-tail keywords: anti-twist neutral buoyancy cable for deep ocean, reinforced core tether for 7000m exploration, stable structure subsea cable for ROV/AUV.

Key Technical Specifications

| Parameter | Specification | Notes / Standard |

|---|---|---|

| Conductor | Tinned multi-stranded copper (Class 5/6) | IEC 60228 |

| Insulation | Foamed PE or XLPE for buoyancy and dielectric control | Low water absorption, stable dielectric |

| Strength Member | Aramid/Kevlar braided core | Tensile load ≥2,500 kg |

| Shielding | Triple-layer foil + braid + polymer | ≥90% coverage for EMI/RFI suppression |

| Outer Jacket | TPU or polyurethane, abrasion-resistant | Resistant to biofouling and corrosion |

| Buoyancy | Neutral in seawater | Density 1.01 ± 0.02 g/cm³ |

| Operating Temperature | –40°C to +75°C | Suitable for extreme ocean conditions |

| Voltage Rating | 300/600V standard (1kV optional) | Safe for power/control circuits |

| Certifications | ISO 9001, RoHS, REACH, optional ABS/DNV | Verified for reliability |

Frequently Asked Questions (FAQ)

Q: How does the anti-twist design work?

A: The cable uses helically twisted cores and reinforced aramid members to prevent rotation under torsion, ensuring stable ROV/AUV operation.

Q: Can the buoyancy be customized for specific salinity or freshwater conditions?

A: Yes. Factory calibration allows precise neutral buoyancy adjustments to suit varying water densities.

Q: Is this cable suitable for long-term deployments at extreme depths?

A: Absolutely. Tested up to 7,000 meters with high-strength cores, abrasion-resistant jackets, and multi-layer shielding.

Q: Are fiber optic channels available for high-speed data transmission?

A: Yes. Fiber-optic integration is available for hybrid power/data or video/control applications.

Q: Can you provide pre-terminated or connector-ready assemblies?

A: Yes. Full pre-termination with SubConn®, SEACON, or custom connectors is offered along with electrical and pressure testing.