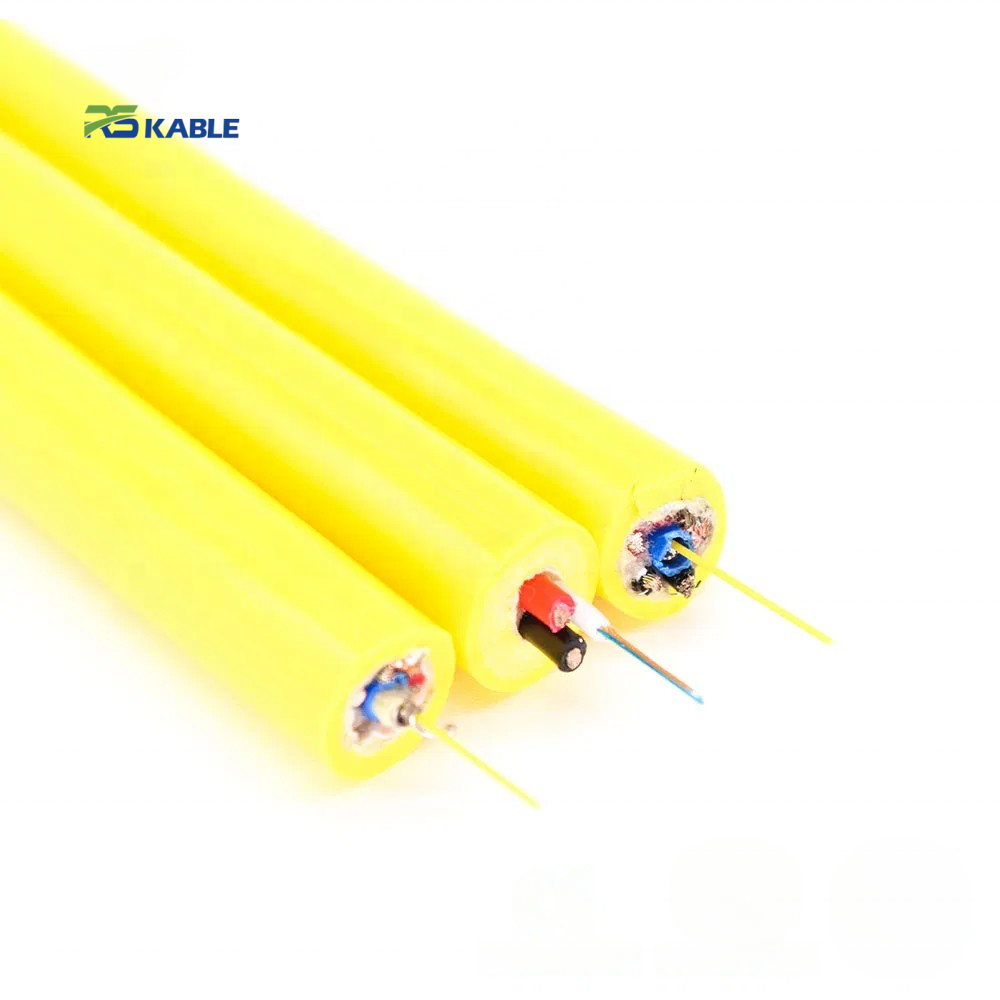

Custom Twisted Pair Anti-Seawater ROV Umbilical Cable | 2/4/6/8 Core Underground Robot Cable for Subsea Applications

.Engineered twisted pair subsea cable with anti‑seawater protection for ROV and robotics applications.

.Available in 2/4/6/8 core configurations to support power, control, and signal needs.

.Rugged construction resists corrosion, abrasion and flex stress in demanding environments.

.Custom lengths and jacket materials tailored to industrial deployment requirements.

.Produced by Shanghai Rousheng — specialists in high‑flex and special‑purpose cable solutions.

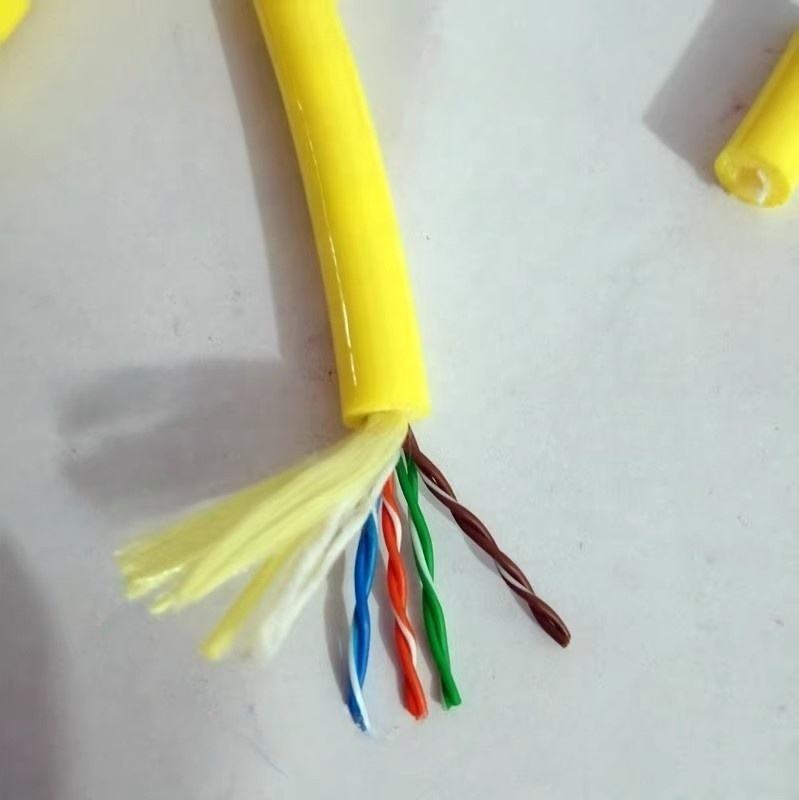

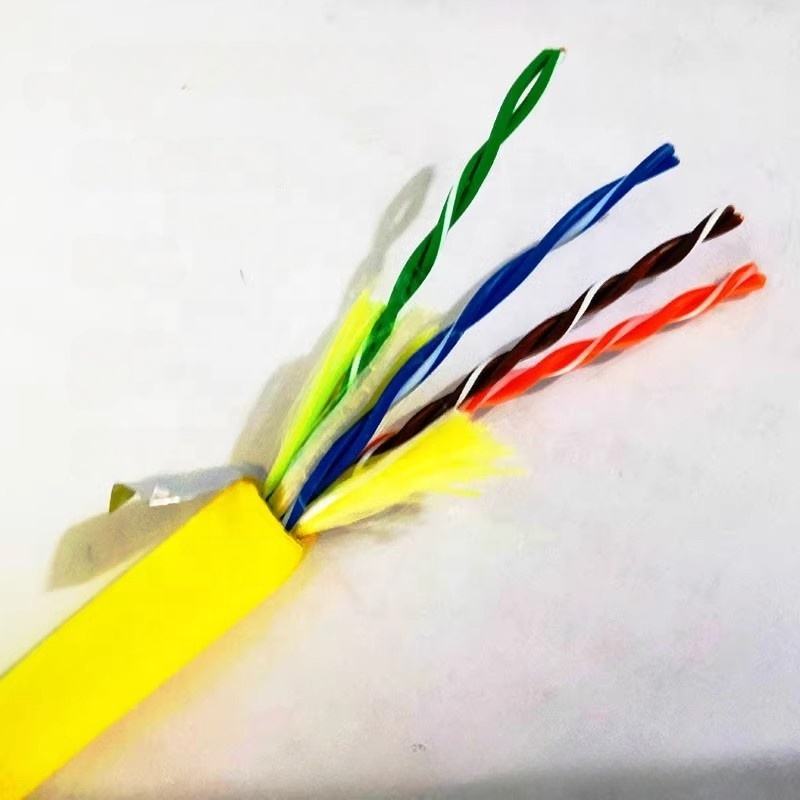

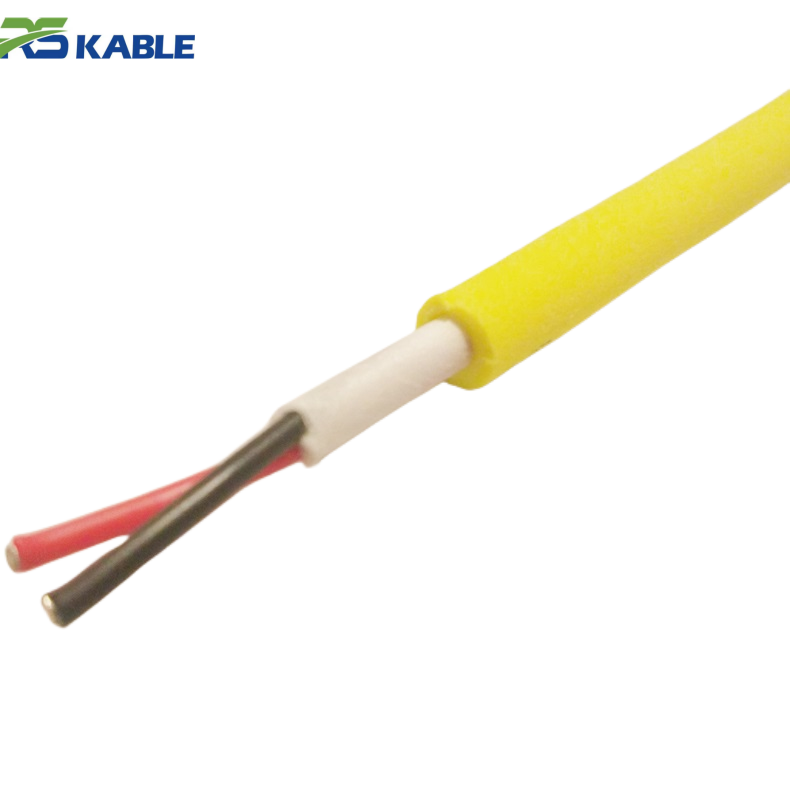

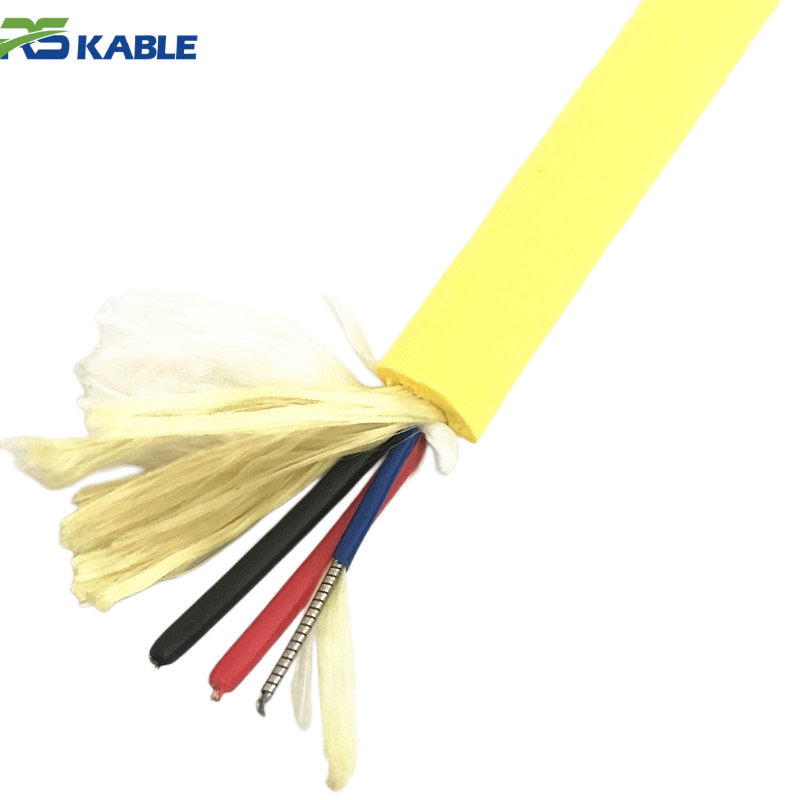

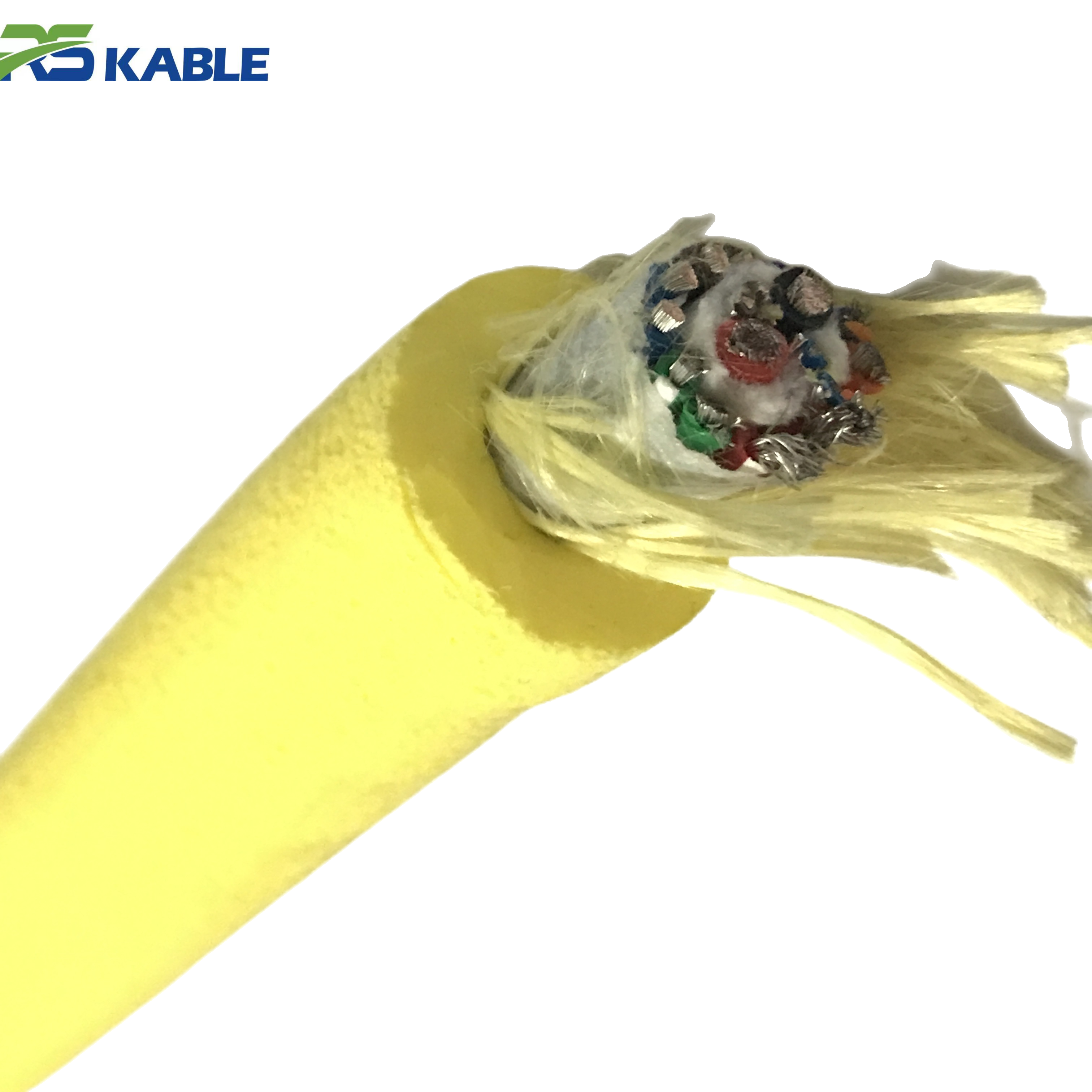

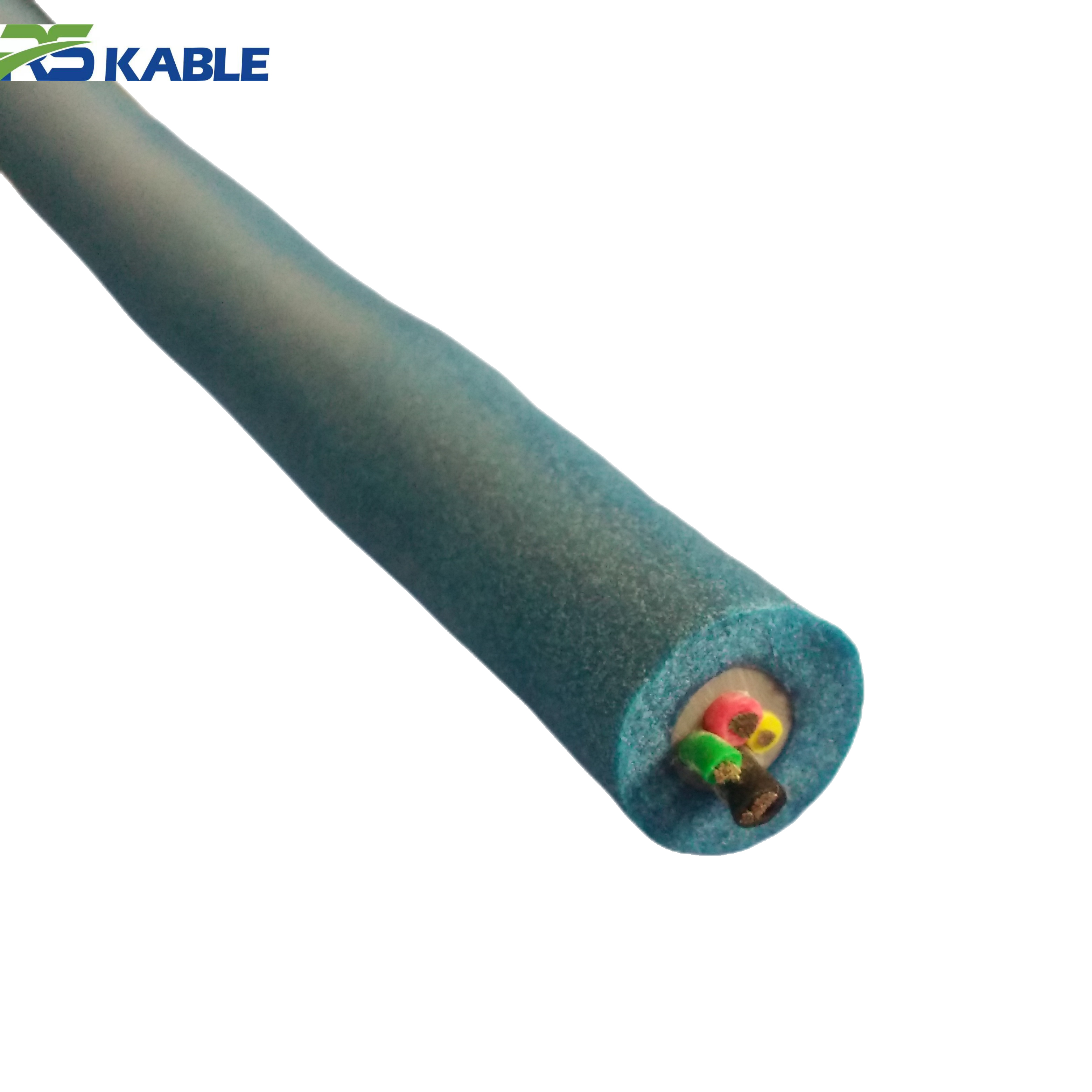

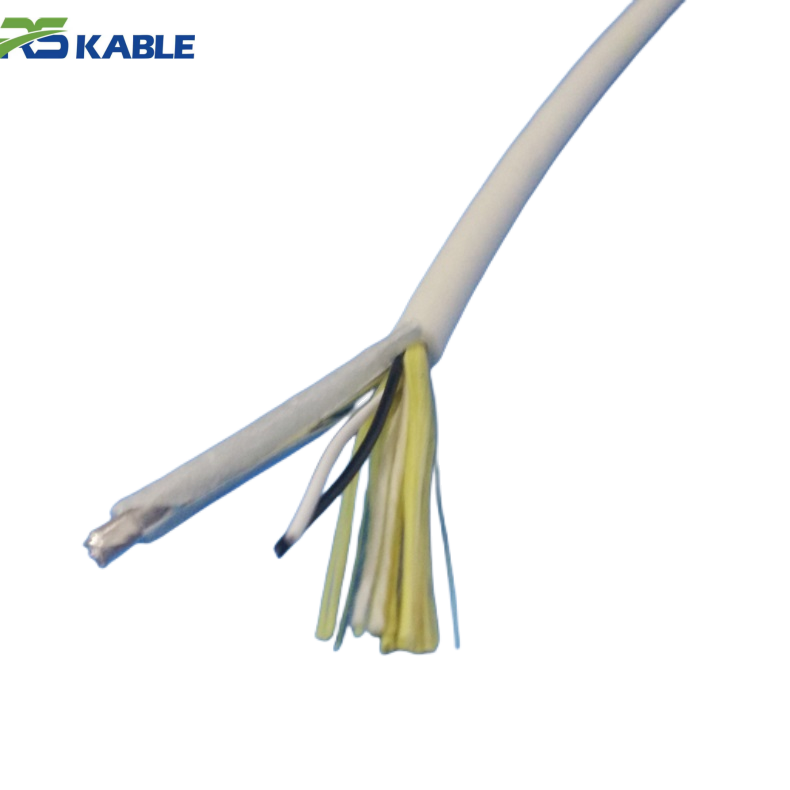

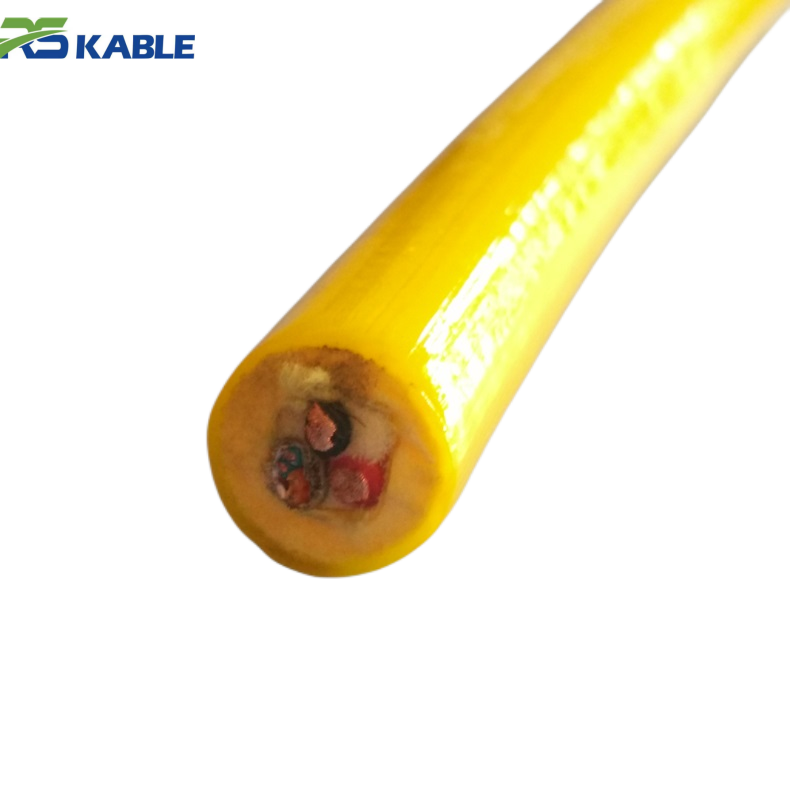

This subsea‑ready ROV umbilical cable is specifically engineered to meet the demands of underwater and underground robotics systems. It integrates robust twisted pair conductors with protective layers designed to resist seawater corrosion, mechanical abrasion, and long‑term deployment stresses. Available in 2, 4, 6, and 8 core configurations, the cable supports power, signal, and communication needs for ROVs, inspection robots and ancillary subsea equipment.

Shanghai Rousheng Wire & Cable Co., Ltd. has decades of experience in developing and manufacturing more than 100 types of high‑flex and special‑purpose cables. Every product is built for reliability, serviceability and global performance.

Built for Harsh Environments

-

Seawater Resistance: Outer jackets and internal materials are selected to withstand corrosive marine conditions and long‑term submersion.

-

Mechanical Durability: Reinforced construction reduces damage from abrasion, repeated flexing and tension during deployment and retrieval.

Flexible and Customizable

-

Twisted Pair Design: Minimizes electromagnetic interference and supports stable signal transmission.

-

Core Options: Choose from 2, 4, 6 or 8 core layouts to match your power and communication requirements.

-

Custom Lengths & Jackets: Cable length and outer jacket material can be tailored to your application.

Optimized for Underwater & Underground Robotics

-

ROV Umbilical Use: Designed for remotely operated vehicles requiring stable electrical and signal continuity.

-

Underground Robotic Systems: Suitable for tethering subsurface inspection robots where moisture resistance and flexibility are essential.

Technical Specifications

| Attribute | Details |

|---|---|

| Cable Type | Twisted Pair Umbilical Cable |

| Core Count | 2 / 4 / 6 / 8 cores |

| Conductor | Stranded Copper |

| Pair Configuration | Twisted Pair |

| Insulation | PE / Custom Options |

| Jacket | PUR / TPE / Other Rugged Materials |

| Seawater Protection | Enhanced Water‑Resistant Construction |

| Operating Temp | Industrial Range |

| Application | ROV, Subsea & Underground Robots |

Design Highlights

Corrosion & Water Resistance

Specialized materials prevent water ingress and resist the corrosive effects of saltwater, ensuring signal integrity and longevity.

Flexibility Under Load

The stranded conductor structure ensures the cable remains flexible even under movement or vibration, reducing stress on connectors and winches.

Modular Core Design

Different core configurations let you balance electrical, control, and communication requirements in a single cable assembly.

Installation & Handling Tips

-

Bend Radius: Follow recommended bend radius guidelines during installation to avoid internal damage.

-

Connector Compatibility: Pair with appropriately rated subsea or industrial connectors for sealing performance.

-

Storage & Handling: Keep clean and free of sharp bends to preserve cable integrity.

Frequently Asked Questions

Q1: What makes this cable suitable for seawater environments?

A: The cable uses water-resistant insulation and rugged jackets that inhibit moisture penetration and withstand prolonged exposure.

Q2: Can I choose different core counts?

A: Yes, you can specify 2, 4, 6 or 8 core configurations based on your power and communication needs.

Q3: Is the cable flexible enough for ROV tethering?

A: Yes. The stranded conductor design and flexible jackets are specifically chosen to support dynamic use in tethered systems.

Q4: Can the cable be customized in length?

A: Absolutely. Length can be tailored to project requirements.

Q5: What outer jacket materials are available?

A: Common options include PUR and TPE, selected for flexibility and abrasion resistance.