Custom TVVBG24 Flat Elevator Traveling Cable | High‑Flex Power & Signal Tether for Hoist Systems

.High-tensile dual steel wire support for long suspension lengths

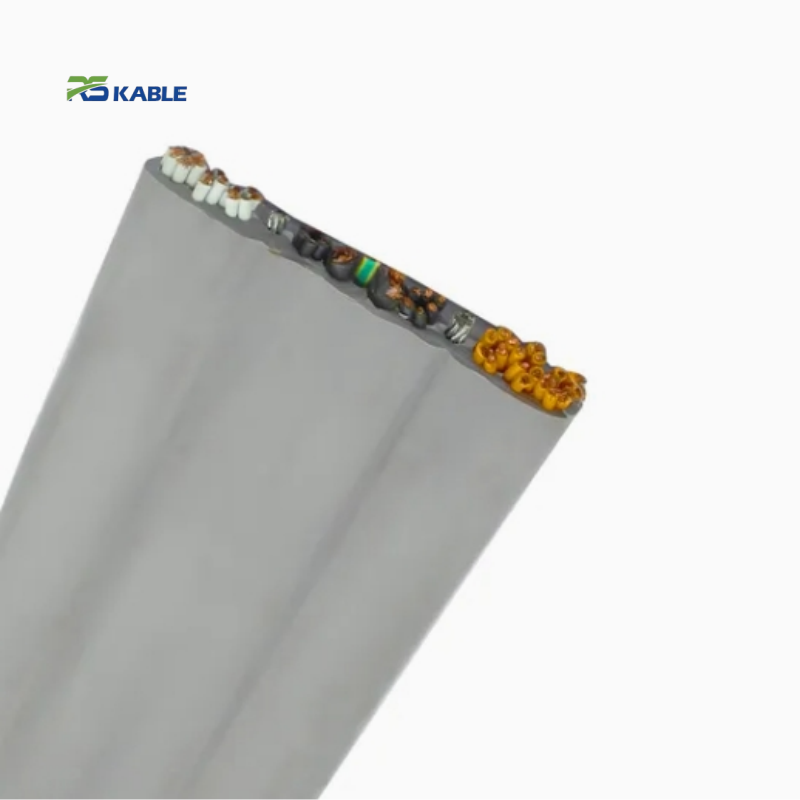

.Special soft PVC sheath ensures smooth loop formation and minimal bending radius

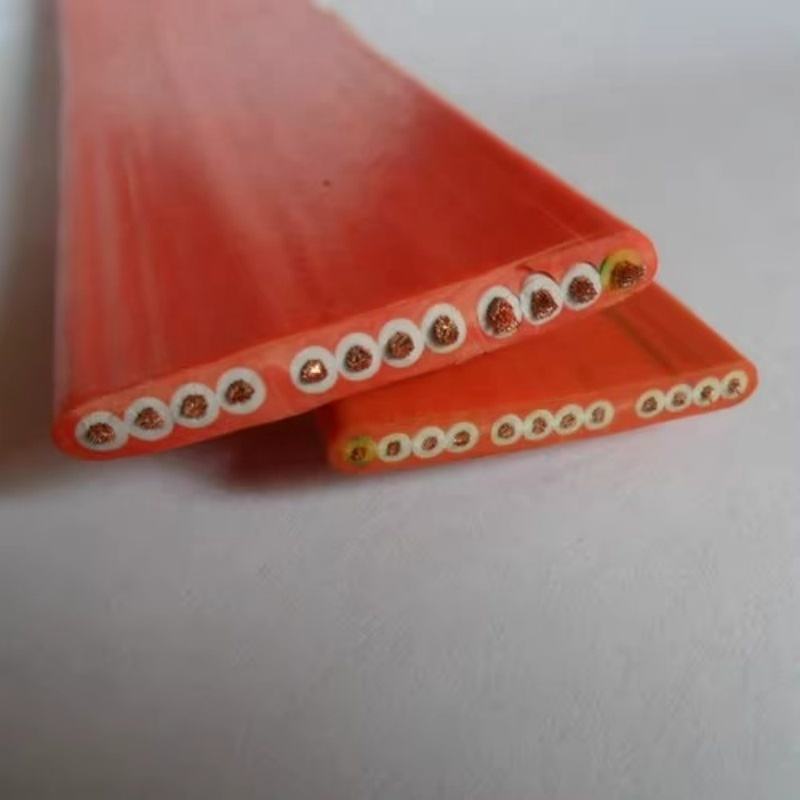

.Rated for 300/500V and 450/750V applications with oxygen-free copper

.Oil, abrasion, and cold-resistant (-15°C) for harsh shaft environments

.Direct from Shanghai Ruosheng factory with custom core counts available

Elevator systems demand more than just standard wiring; they require a lifeline that provides consistent power and data transmission while enduring constant motion. The TVVBG24 Flat Elevator Traveling Cable is engineered specifically for this purpose.

Manufactured by Shanghai Ruosheng Wire & Cable Co., Ltd., a specialist in high-flex and drag chain solutions, this cable addresses the two biggest headaches in vertical transportation: cable twisting and mechanical fatigue. Unlike standard round cables, our flat design stacks cores side-by-side to minimize the bending radius and eliminate the internal stress that leads to corkscrewing.

Whether you are retrofitting a mid-rise freight elevator in Berlin or specifying components for a high-speed passenger lift in Dubai, this cable offers the tensile strength and flexibility required for safety and longevity.

Why Engineering Teams Choose the TVVBG24

1. Built for Suspension (Steel-Reinforced)

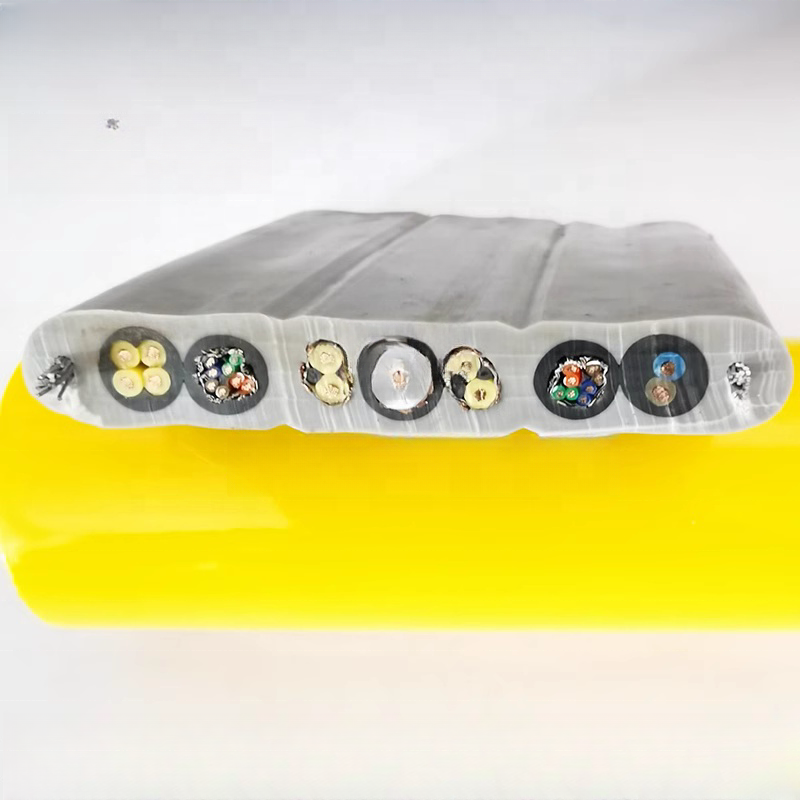

The “G” in TVVBG signifies the inclusion of dual galvanized steel wire ropes integrated directly into the outer sheath. This reinforcement absorbs the tensile load, allowing for longer free-hanging lengths without stretching the copper conductors. It effectively prevents the “elongation” issues common in tall hoistways.

2. Extreme Flexibility & Small Bending Radius

Space in the elevator shaft is premium real estate. Our special soft PVC compound allows for a tighter bending radius compared to standard rubber cables. The flat profile ensures the cable folds neatly upon itself during the ascent and descent, reducing the space required for the loop.

3. Cold & Oil Resistant durability

Elevator shafts are not always climate-controlled. The TVVBG24 features a specialized outer sheath that remains flexible down to -15°C and resists cracking. It is also formulated to resist oil and grease, common contaminants in industrial lift environments.

Technical Specifications

|

Feature |

Specification |

|---|---|

|

Product Model |

TVVBG24 (Flat Traveling Cable with Steel Support) |

|

Rated Voltage |

300/500V (for signal/control sections); 450/750V (for power sections >1.5mm²) |

|

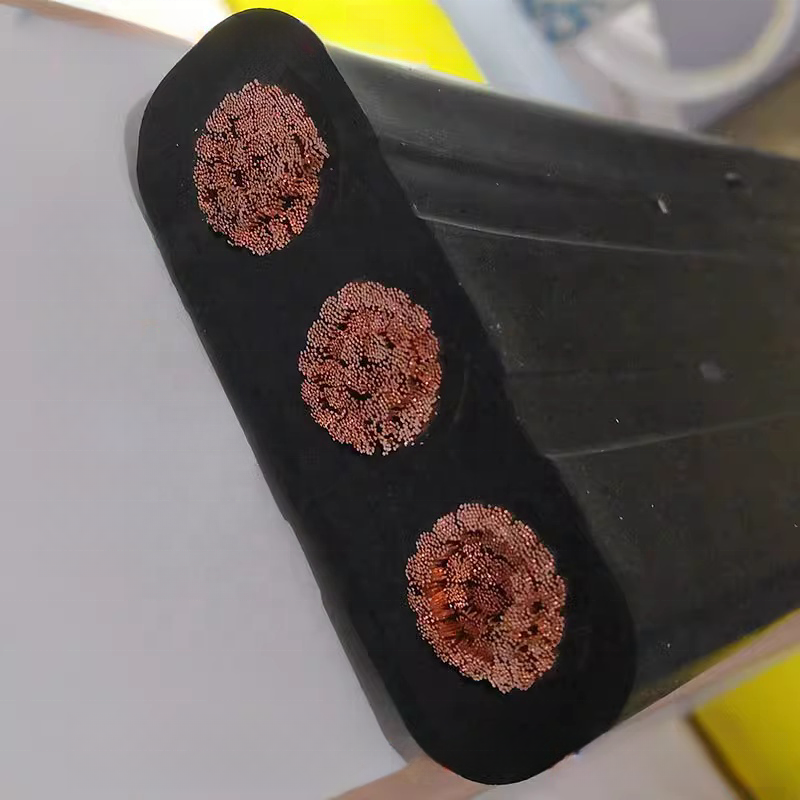

Conductor Material |

Oxygen-free Fine Stranded Copper (Class 5 Flexibility) |

|

Insulation Material |

Special Soft PVC (Polyvinyl Chloride) |

|

Reinforcement |

Dual Galvanized Steel Wire Ropes (integrated in sheath) |

|

Sheath Material |

Cold-resistant, Flame-retardant specialized PVC |

|

Operating Temperature |

-15°C to +70°C (Static installation allows lower temps) |

|

Test Voltage |

2500V |

|

Flame Retardancy |

Compliant with IEC 60332-1 standards |

|

Standard Length |

Custom cut or bulk drums (100m, 500m, 1000m) |

Customization: The “Factory Direct” Advantage

At Shanghai Ruosheng, we don’t just stock cable; we engineer it. Because we control the manufacturing process, we can adapt the TVVBG24 to your specific project requirements:

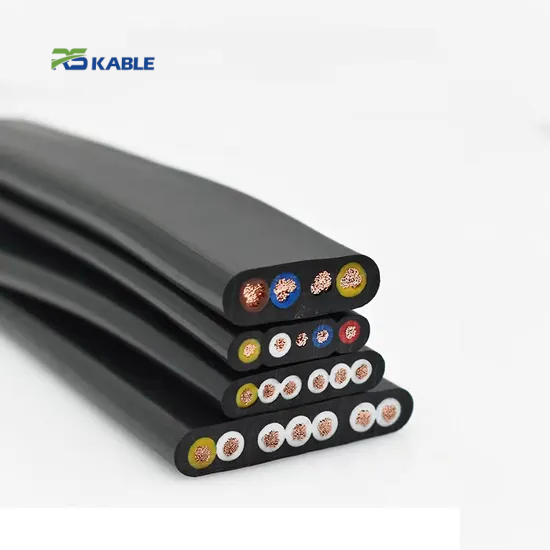

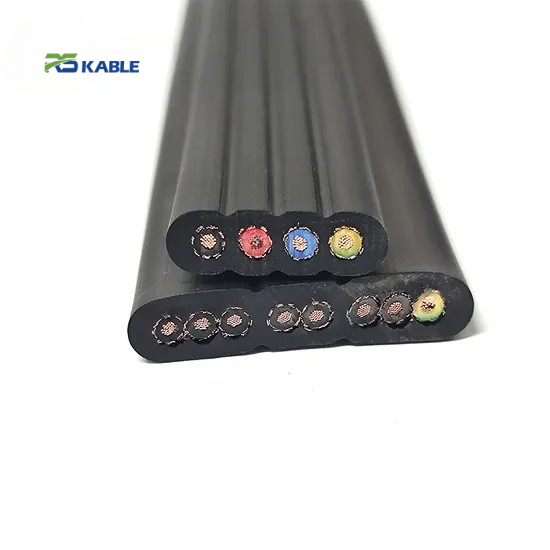

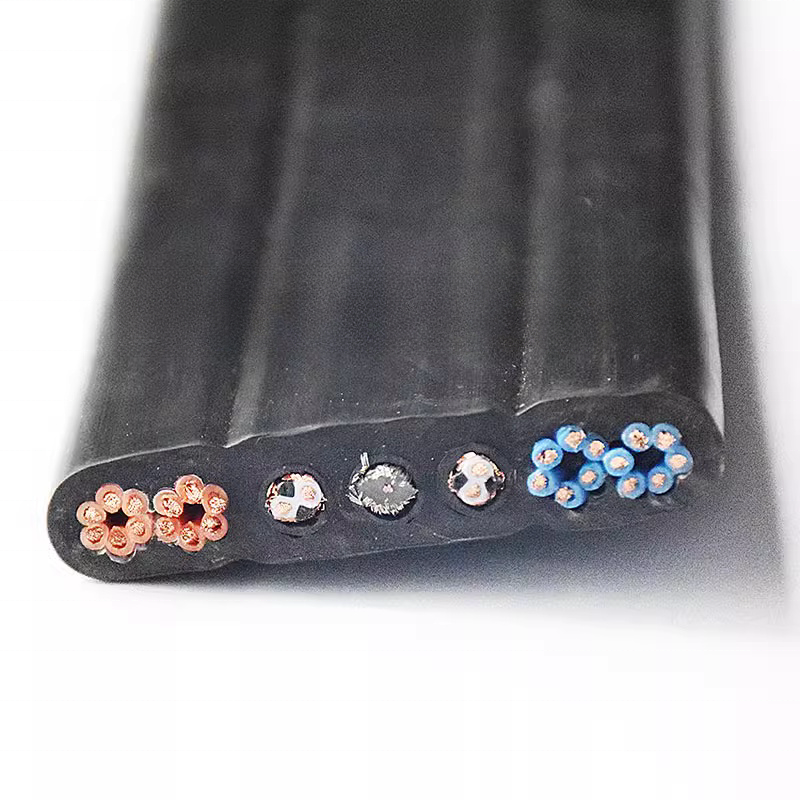

- Hybrid Cores: Combine power cables (up to 40 cores) with shielded pairs for data communication or fiber optics in a single flat tether.

- Identification: Custom text printing on the sheath for branding or easy circuit identification during maintenance.

- Dimensions: Modifications to width and thickness to fit specific guide rails or clamps.

Frequently Asked Questions (FAQ)

Q: What is the difference between TVVB and TVVBG cables?

A: The primary difference is tensile strength. TVVB is a standard flat cable suitable for lower heights. TVVBG includes two steel wires in the outer sheath, providing the extra suspension support needed for taller buildings and longer travel distances.

Q: What is the recommended free suspension length for this cable?

A: Thanks to the steel wire reinforcement, the TVVBG24 typically supports a free suspension length of up to 80 meters. For heights exceeding this, please consult our engineering team for a customized strengthening solution.

Q: Does this cable meet European standards?

A: Yes. Our cables are manufactured in strict accordance with relevant IEC and EN standards for lift cables. We use VDE-compatible PVC compounds to ensure compliance with European safety and environmental regulations (RoHS).

Q: Can this cable be used for outdoor construction elevators?

A: While the TVVBG24 is robust, it is primarily designed for enclosed shaftways. For outdoor construction hoists exposed to direct UV radiation and extreme weather, we recommend our specialized outdoor-rated hoist cables. Contact us for the specific model.

Q: How do you package the cable to prevent damage during shipping?

A: We understand that flat cables can be damaged if spooled incorrectly. We use high-strength wooden drums or reels, ensuring the cable is laid flat without twisting, and wrap it in protective plastic for ocean or air freight.