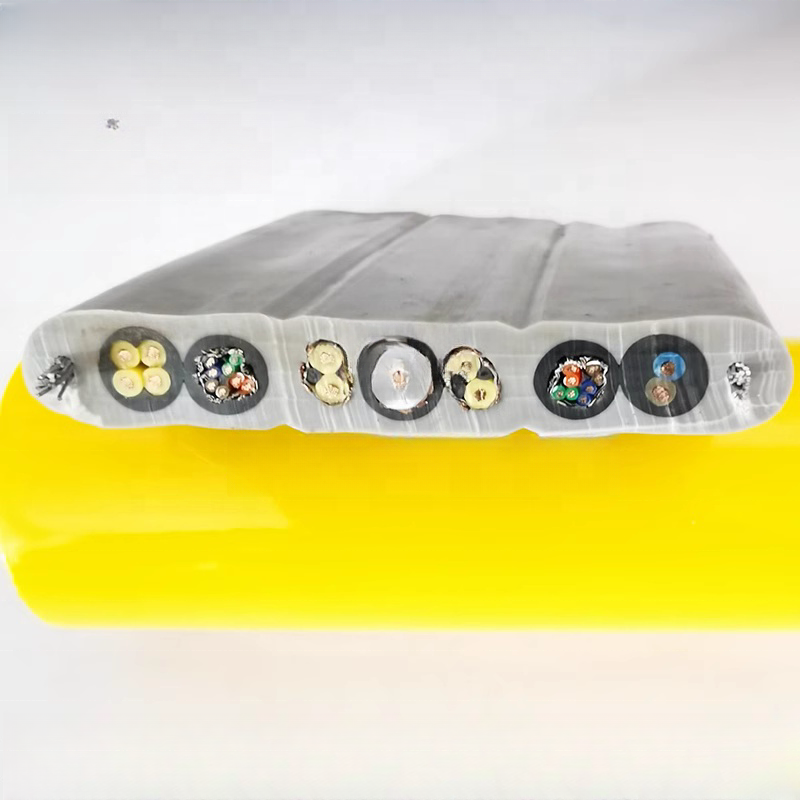

Custom TVVB Flexible Flat Lift Cable | 0.75 mm 3/4/7/12 Core Elevator Cable

. Model: TVVB Flat Traveling Cable

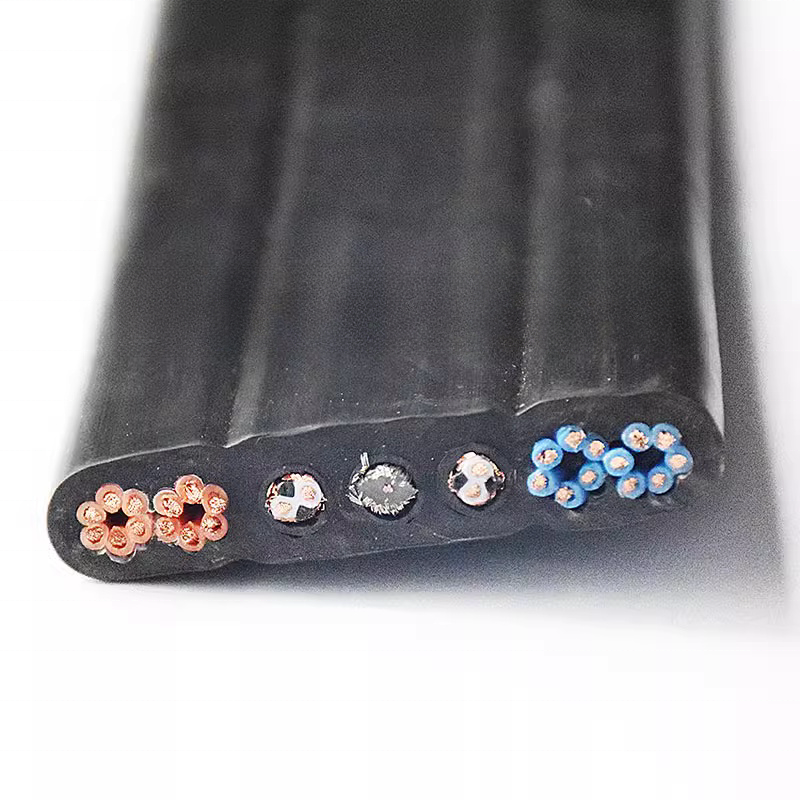

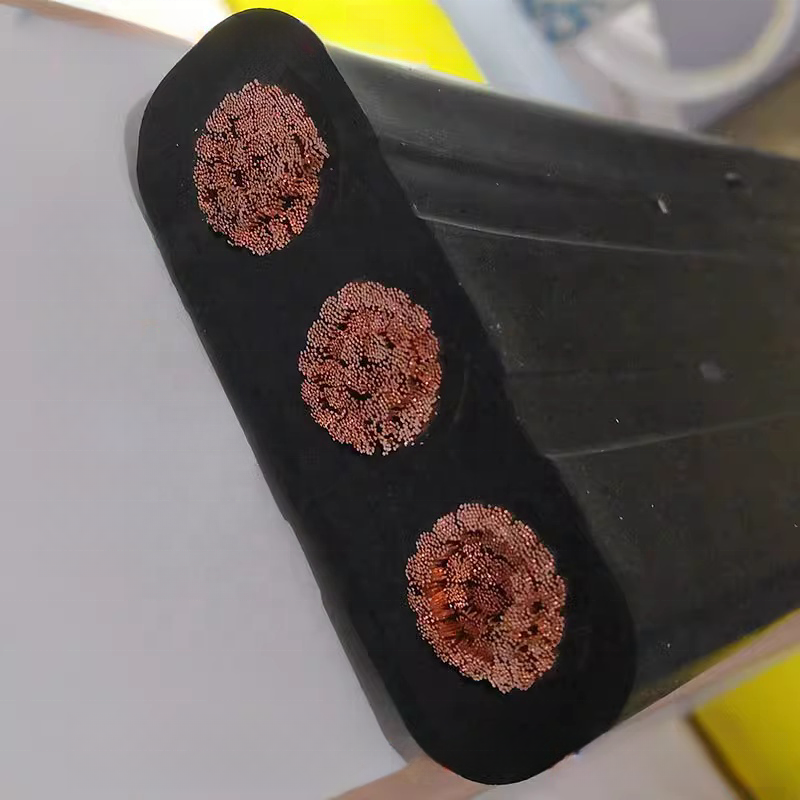

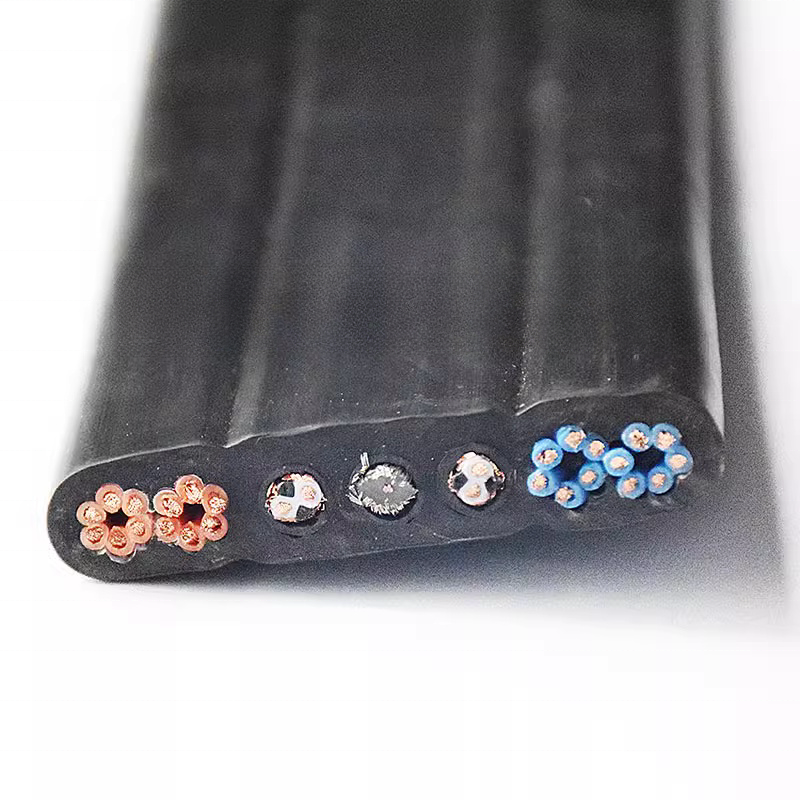

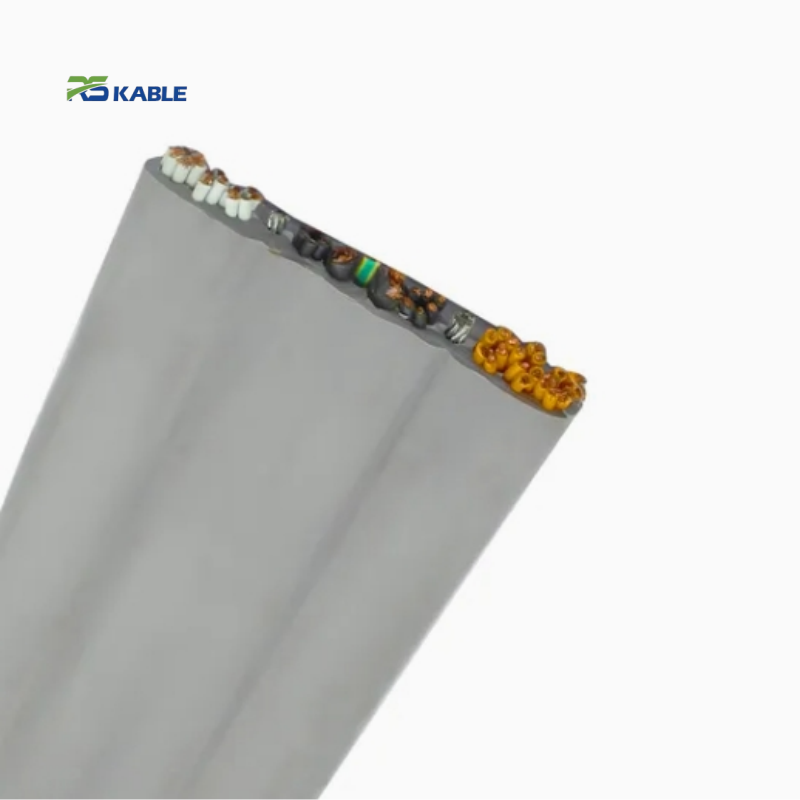

. Conductor: 0.75 mm² Stranded Oxygen-Free Copper

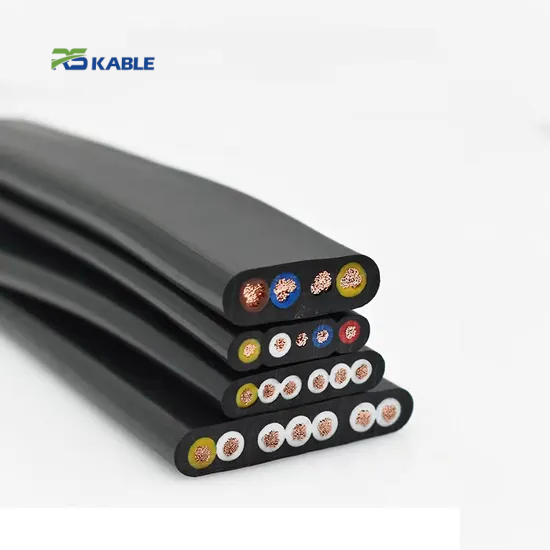

. Core Options: 3, 4, 7, 12, up to 60+

. Jacket: Flame-retardant, Oil-resistant Special PVC

. Application: Passenger Elevators, Cargo Lifts, Gantry Cranes

The Lifeline of Vertical Transportation: Reliable, Flexible, and Built to Last

In the elevator industry, signal integrity and power transmission are non-negotiable. The Custom TVVB Flexible Flat Lift Cable is engineered to withstand the rigorous demands of constant motion, vertical suspension, and bending stress.

Manufactured by Shanghai Ruosheng Wire and Cable Co., Ltd., this cable represents the intersection of safety and durability. With over 100 varieties of special cables in our portfolio and a global footprint spanning Europe and beyond, we understand that every lift system has unique requirements. Whether you need a standard 12-core control cable or a custom 3-core power solution, Ruosheng provides the flexibility—literally and figuratively—that your project demands.

Why Choose Ruosheng TVVB Flat Cables?

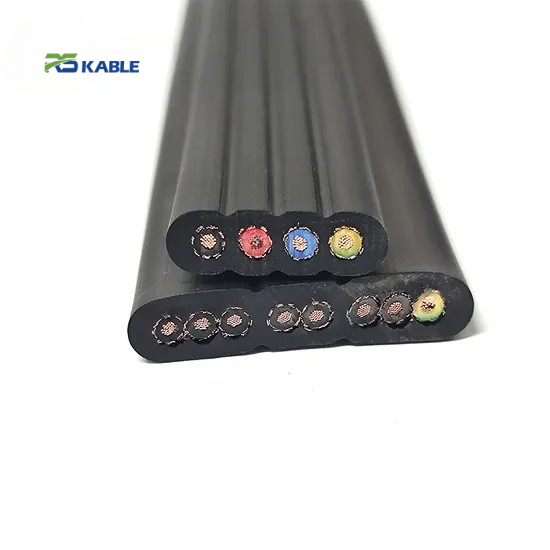

Unlike standard round cables that can twist or knot during operation, our flat parallel structural design ensures stability during high-speed travel.

- Superior Flexibility: Engineered with high-quality, fine-stranded oxygen-free copper and special soft insulation materials. This design allows for a smaller bending radius and millions of flex cycles without conductor fatigue.

- Tangle-Free Operation: The flat geometry allows the cables to stack neatly in the elevator shaft, significantly reducing the risk of spiraling or kinking that leads to system downtime.

- Customization at Scale: While we offer standard 0.75 mm² configurations, we specialize in tailoring the core count (3 to 60+ cores) and integrating steel wire reinforcement for high-rise applications with long suspension lengths.

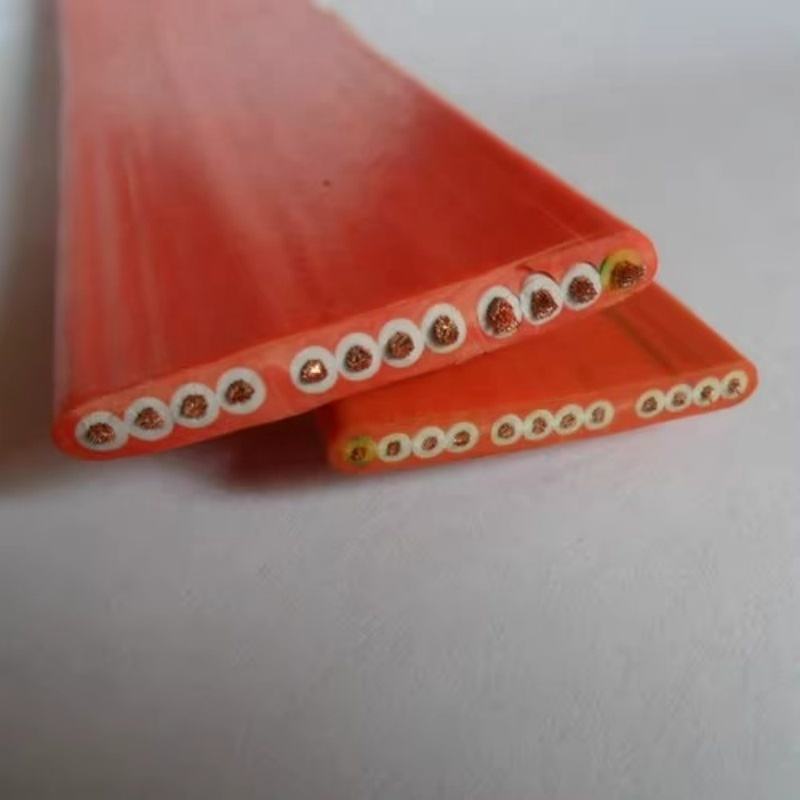

- Safety Compliance: Our cables utilize flame-retardant special PVC/Rubber composite sheathing, offering excellent resistance to oil, cold, and aging, ensuring compliance with strict global safety standards.

Technical Specifications

We offer fully customizable configurations. Below is the standard data for our popular 0.75 mm² series.

|

Property |

Specification |

|---|---|

|

Model |

TVVB (Flat Elevator Traveling Cable) |

|

Conductor Material |

Class 5 / Class 6 Stranded Oxygen-Free Copper |

|

Insulation/Sheath |

Special Flexible PVC / Nitrile Composite (Oil & Cold Resistant) |

|

Rated Voltage |

300/500V (for ≤0.75mm²); 450/750V (for ≥1.0mm²) |

|

Core Cross-Section |

0.75 mm² (Standard) |

|

Available Cores |

3, 4, 7, 12 (Standard Stock); 6, 16, 18, 24, 30+ (Custom) |

|

Temperature Range |

-15°C to +70°C (Static); -5°C to +70°C (Flexing) |

|

Free Suspension |

Max 45m (Standard); >80m requires steel wire reinforcement |

|

Travel Speed |

Up to 4.0 m/s |

|

Standards |

IEC60227-6, EN50214, CE, RoHS |

Note: For installations exceeding 45 meters of free suspension length, please request our reinforced version with dual steel support wires to prevent tensile strain on the copper conductors.

Frequently Asked Questions (FAQ)

Q: What is the difference between TVVB and round elevator cables?

A: TVVB (flat) cables are specifically designed for the tight bending radii of elevator operation. Their flat shape dissipates heat better and prevents the “corkscrew” twisting effect common in round cables over long vertical distances.

Q: Can you customize the core color coding?

A: Yes. Our standard manufacturing follows the IEC/EN code (Black cores with white numbering + 1 Green/Yellow Ground), but we can customize insulation colors for specific project identification requirements upon request.

Q: Is this cable suitable for outdoor panoramic elevators?

A: Standard TVVB is designed for indoor shafts. For outdoor panoramic lifts, we recommend our upgraded weather-resistant jacket option, which provides enhanced protection against UV radiation and extreme cold. Please specify “Outdoor Use” when quoting.

Q: What is the Minimum Order Quantity (MOQ) for custom sizes?

A: For standard specifications (like 12-core 0.75mm), we often have stock available for shorter lengths. For fully custom configurations, the MOQ is typically 100 meters, with a production lead time of 10–15 days.

Q: How do you ensure the quality of the copper?

A: We use only 99.99% oxygen-free copper. Lower-grade copper (like CCA) increases resistance and heat, risking fire. You can test our cable by checking the conductor resistance—it will always meet or exceed IEC standards.