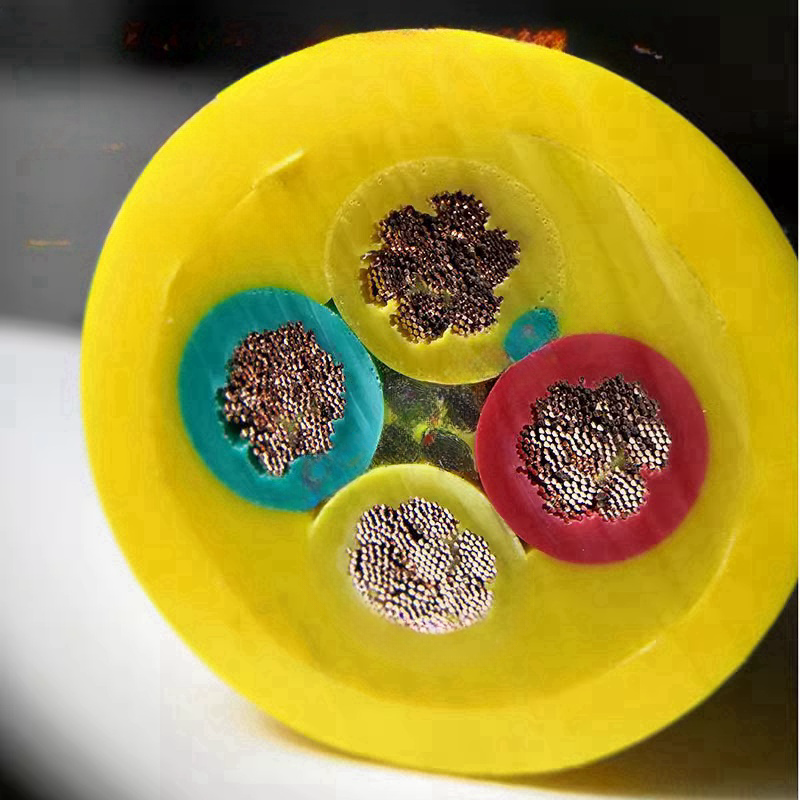

Custom Industrial 3-Core PVC Reel Cable 3×16/25 + 1×10/16 | Copper Conductors with Steel Reinforcement

.Core configuration: 3 Power + 1 Ground (e.g., 3×16+1×10)

.Voltage rating: 600/1000V for heavy industrial power

.Integrated steel wire prevents conductor breakage under tension

.Minimum bending radius of 8x OD for smooth reeling

.Flame retardant to IEC 60332-1-2 standards

.Customizable jacket materials for oil or extreme cold resistance

Stop replacing cables that can’t handle the tension. Engineered for high-stress reeling systems.

In heavy industrial environments like ports, mines, and manufacturing plants, standard cables fail under the constant stress of retraction and payout. The Ruosheng Custom Industrial Reeling Cable is built specifically to solve this problem. By integrating high-tensile steel wire reinforcement directly into the cable structure, we ensure the mechanical load is carried by the steel—not the copper conductors—preventing breakage and costly downtime.

Whether you are powering a gantry crane or a mobile conveyor system, this cable delivers the flexibility of Class 5 copper with the rugged durability needed for dynamic drum operations.

Why Choose This Steel-Reinforced Reeling Cable?

1. Zero-Tension Copper Transmission

The primary failure point in reeling cables is conductor elongation. Our design utilizes integrated steel wire reinforcement to absorb the tensile load. This ensures your power and control signals (3×16/25 + 1×10/16 configurations) remain stable, even during rapid acceleration or vertical lifts.

2. Engineered for Continuous Flexing

We use VDE 0295 / IEC 60228 Class 5 tinned copper conductors. Unlike standard solid wire, these finely stranded cores are designed to withstand thousands of bending cycles over reeling drums without work-hardening or snapping.

3. Adaptable Jacket Materials

While our standard high-grade PVC jacket offers excellent weather and abrasion resistance for general industrial use, we understand that every environment is different.

- Standard PVC: Ideal for indoor/outdoor general manufacturing.

- Upgrade to PUR/TPU: Recommended for extreme environments requiring cut resistance, oil resistance, or sub-zero flexibility (down to -40°C).

4. Global Compliance & Safety

Manufactured by Shanghai Ruosheng Wire Cable Co., Ltd., this cable meets IEC 60227-5 and EN 50525-2-5 standards. It is flame retardant (IEC 60332-1-2), ensuring safety in high-risk industrial zones.

Technical Specifications

|

Feature |

Specification |

|---|---|

|

Model |

RSTLKABLE (Custom Series) |

|

Core Configuration |

3 Power Cores + 1 Ground (e.g., 3×16+1×10, 3×25+1×16) |

|

Rated Voltage |

600/1000V (for cross-sections >6.0mm²) |

|

Conductor Material |

Stranded Tinned Copper (Class 5 flexible) |

|

Tensile Member |

Integrated Steel Wire Reinforcement |

|

Insulation |

PE (Polyethylene) for low capacitance |

|

Outer Sheath |

Special PVC (Standard) or PUR/TPU (Optional) |

|

Operating Temp |

-10°C to +80°C (Standard) | Custom: -40°C to +105°C |

|

Bending Radius |

Mobile/Reeling: 8x Cable Outer Diameter |

|

Test Voltage |

2500V / 4000V |

Common Applications

This cable is specifically designed for dynamic machinery where the cable is constantly moving, winding, or unwinding:

- Port Machinery: Ship-to-shore cranes and gantry cranes.

- Material Handling: Vertical lift systems and hoisting equipment.

- Mining: Conveyor systems and drag chains.

- Construction: Temporary power reels and festive/event power supply.

Tailored to Your Project Requirements

At Shanghai Ruosheng, we don’t just sell cable off the shelf; we configure it to your specific machine.

- Extreme Cold? We can formulate the sheath to remain flexible at -40°C for Siberian or Nordic climates.

- High Wear? Upgrade to a Polyurethane (PUR) matte finish for superior abrasion resistance against concrete or steel edges.

- Specific Lengths? We cut to order, reducing your scrap waste.

Frequently Asked Questions (FAQ)

Q: Why is steel reinforcement necessary for drum cables?

A: Standard copper cables will stretch and eventually break under their own weight or the tension of a reeling drum. Steel reinforcement acts as a central strength member, absorbing this physical stress so the copper conductors can simply transmit power without mechanical strain.

Q: Can this cable be used for vertical hanging applications?

A: Yes. The steel reinforcement makes it ideal for vertical hoist or elevator applications where the cable must support its own weight over long distances.

Q: What is the difference between the PVC and TPU jacket options?

A: PVC is cost-effective and suitable for most general outdoor/indoor applications. TPU (Thermoplastic Polyurethane) is a premium material that is significantly more resistant to cuts, oil, grease, and extreme cold. If your cable drags over rough surfaces, we recommend TPU.

Q: What is the minimum bending radius I should maintain?

A: For reeling applications (dynamic movement), you must maintain a radius of at least 8 times the cable’s outer diameter. Tighter bends can damage the internal structure over time.

Q: Does this cable meet European standards?

A: Yes, our manufacturing process aligns with EN 50525-2-5 and IEC standards, making it suitable for export to European and global markets.