Custom High‑Flex Power, Coaxial Signal & Fiber Optic Umbilical ROV Cable | Multi‑Core Subsea Electrical Cable

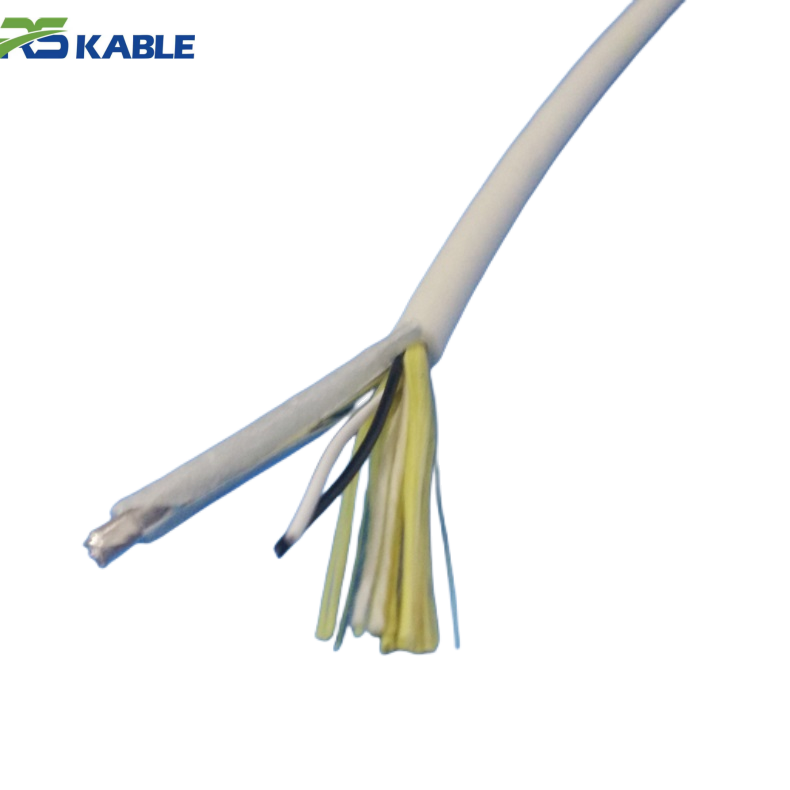

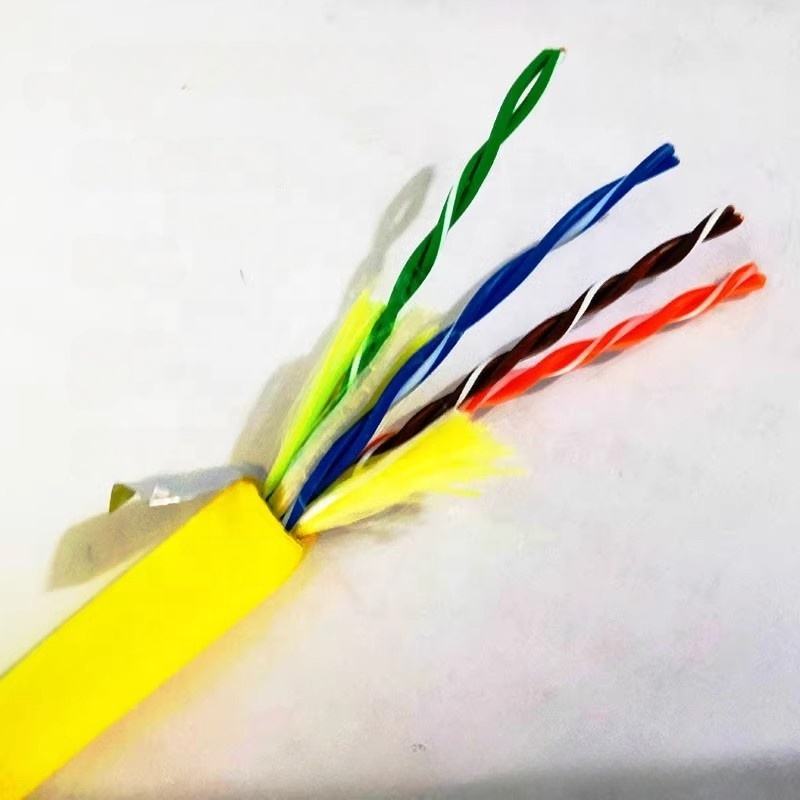

.Customizable core counts (Power/Signal/Fiber)

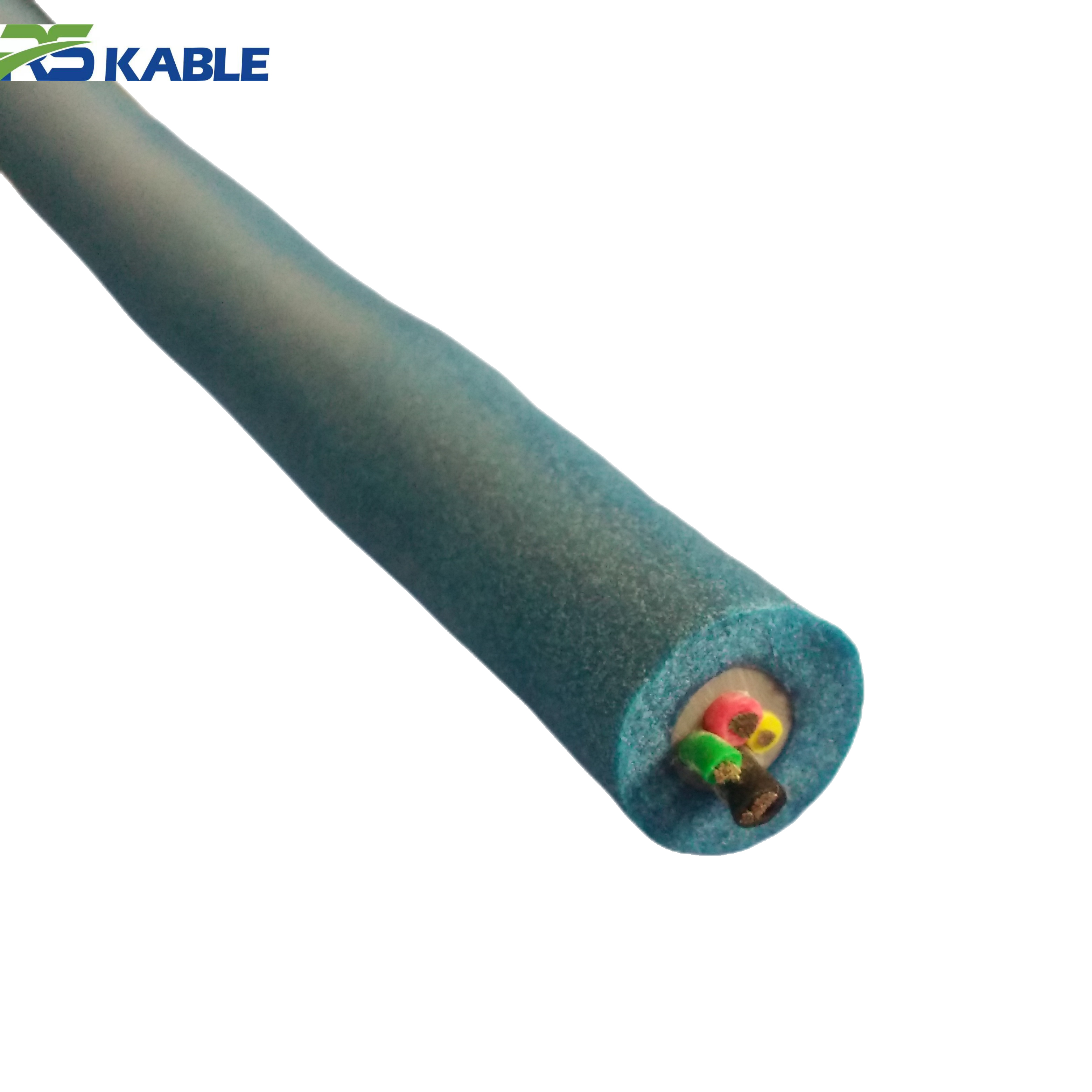

.Neutral buoyancy options available

.High-density shielding for interference-free video

.Saltwater-resistant PUR/Elastomer jacket

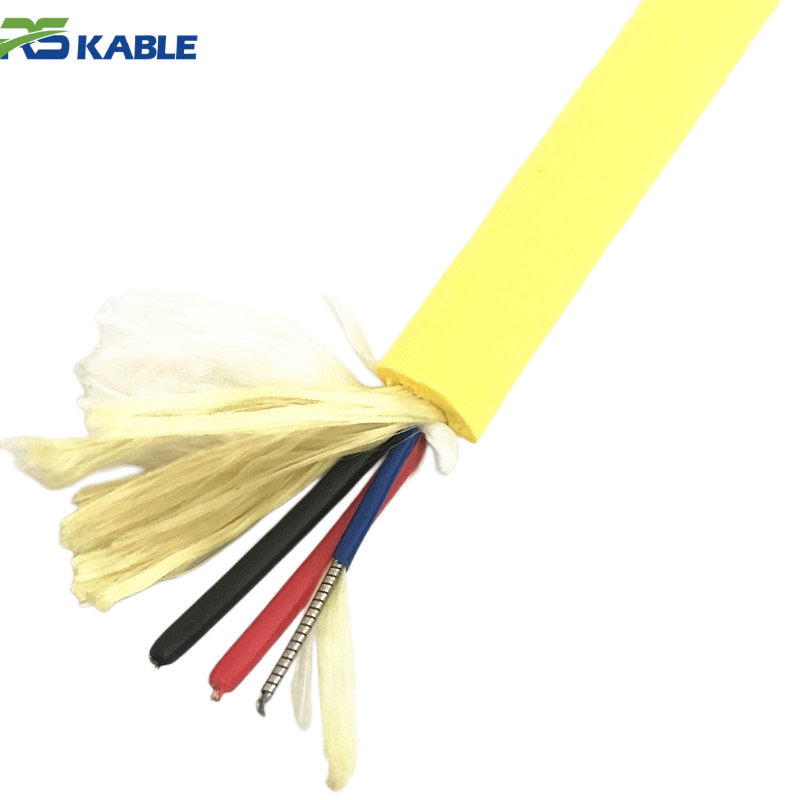

.Kevlar reinforced for high tensile load

In deep-water operations, your tether is your lifeline. This Custom High‑Flex Hybrid ROV Cable is engineered to solve the three most common failure points in subsea operations: signal loss due to electromagnetic interference, sheath degradation from saltwater exposure, and mechanical failure under high tension.

Manufactured by Shanghai Rousheng Wire and Cable Co., Ltd., a specialist in high-flex drag chain and special cables, this umbilical solution integrates power, video (coaxial), and data (fiber optic) transmission into a single, robust line. Whether you are operating inspection class ROVs, underwater crawlers, or deep-sea gliders, this cable ensures stable communication and power delivery in challenging hydrodynamic environments.

Why Choose This Hybrid Umbilical?

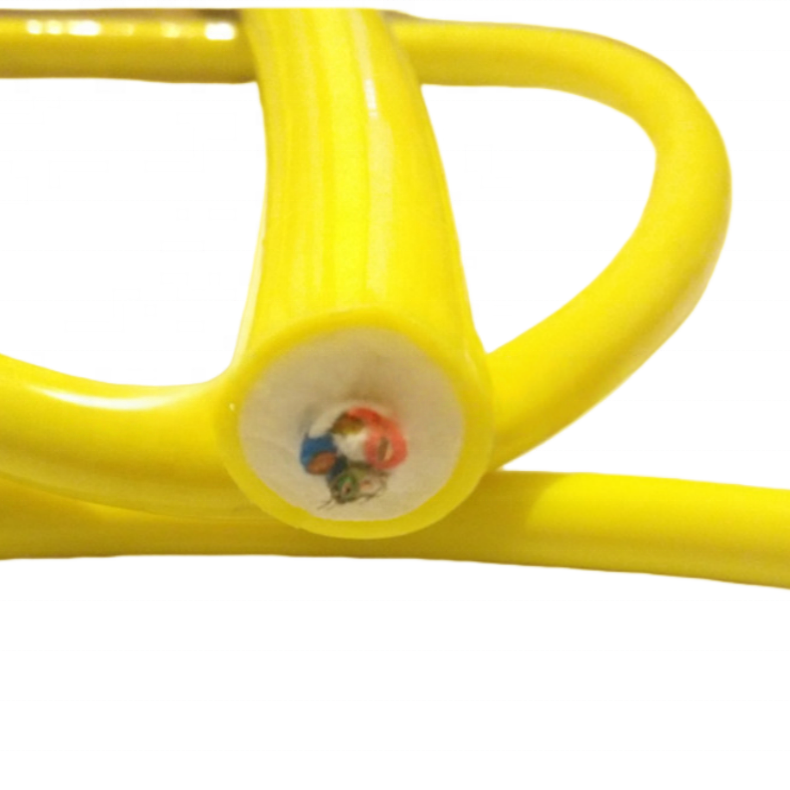

1. Zero Buoyancy & Hydrodynamic Stability

Operating an ROV requires precise maneuverability. We offer Zero Buoyancy (Neutral) options using foam-skin polyethylene or specific structural adjustments. This prevents the cable from sinking and dragging the vehicle down or floating upward and tangling in propellers, ensuring the cable “hovers” neutrally in the water column.

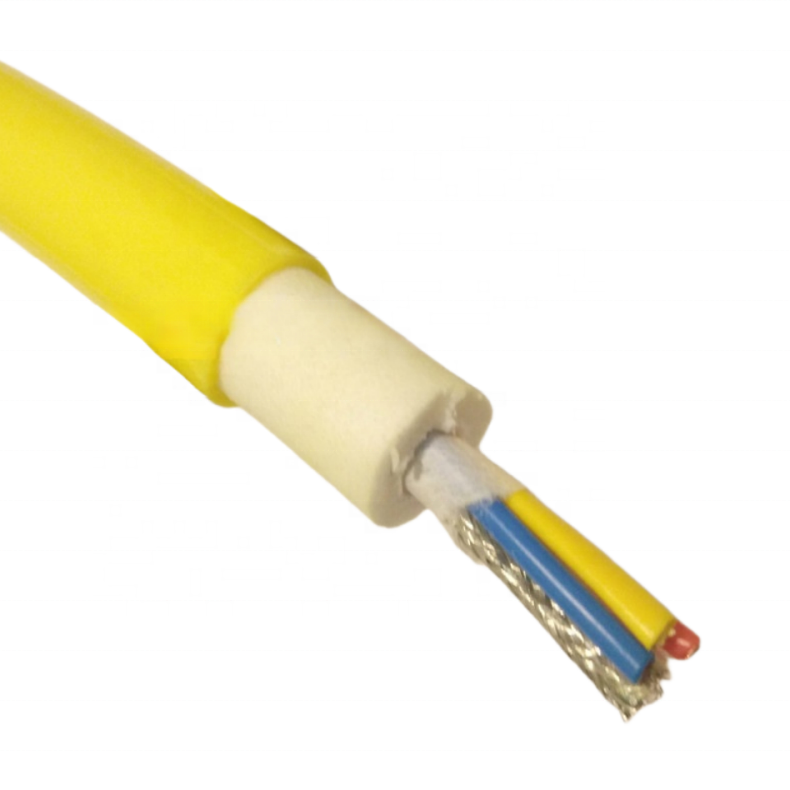

2. Kevlar-Reinforced Tensile Strength

Standard copper cables snap under the weight of deep dives or strong currents. Our cables utilize DuPont Kevlar (Aramid fiber) braiding. This provides exceptional tensile strength—customizable from 100kg to 1000kg—absorbing the mechanical load so the copper conductors don’t have to. This protects the internal cores from breaking during retrieval or towing.

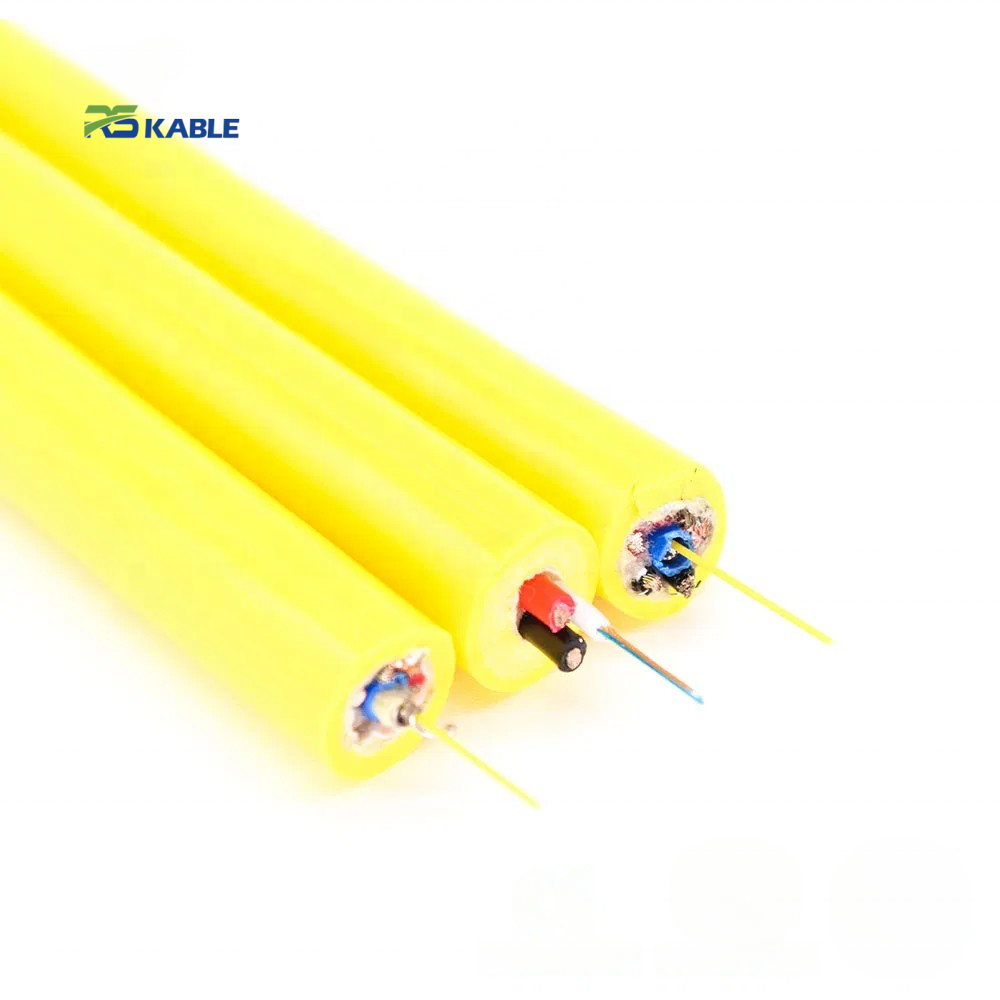

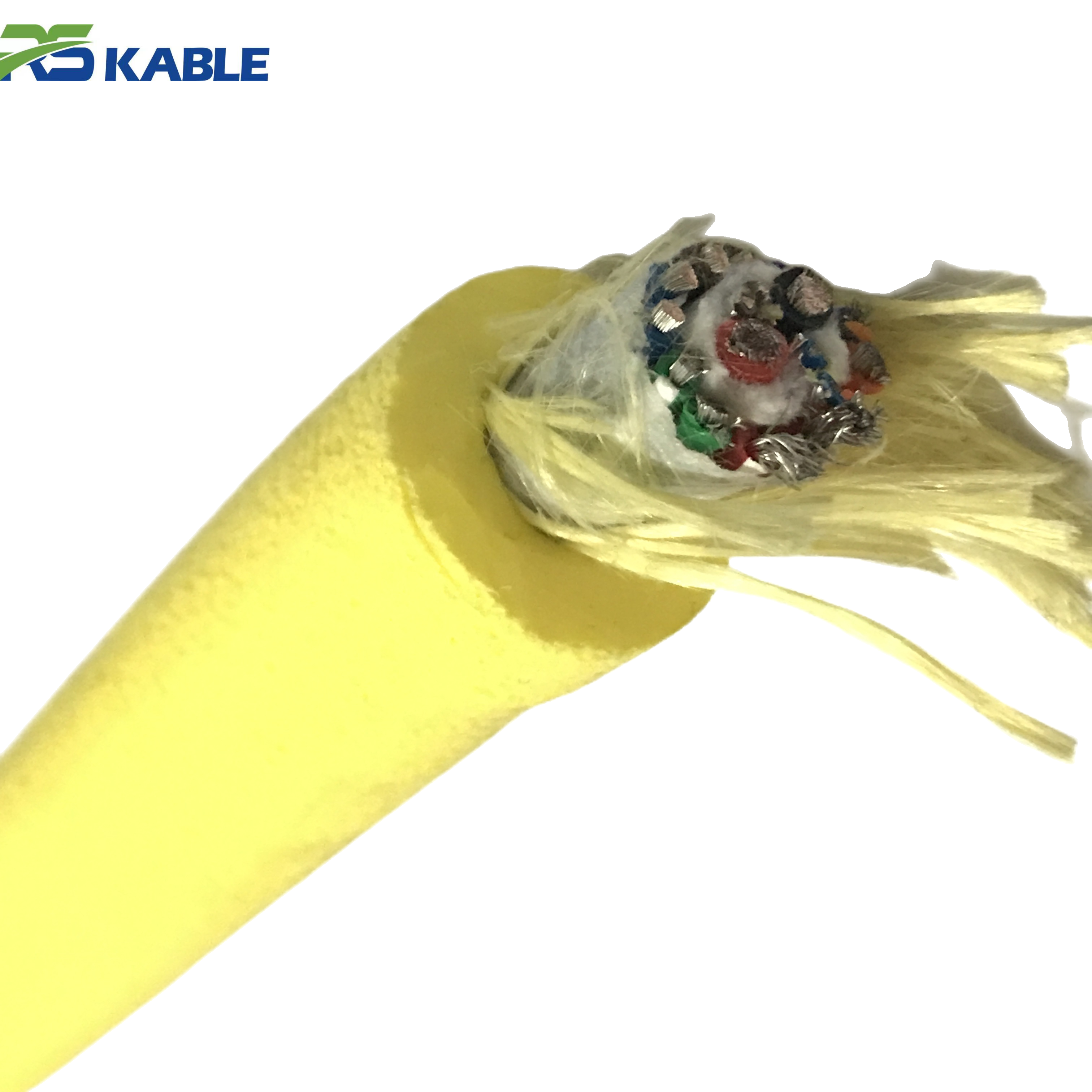

3. Superior Signal Integrity (EMI Shielding)

Subsea environments are noisy. To prevent crosstalk between high-voltage power lines and sensitive data signals, we employ a Double-Layer High-Density Shielding system. This combines aluminum foil wrapping with a tinned copper mesh braid, ensuring clear video feeds and error-free telemetry data even over long distances.

4. Industrial-Grade Durability

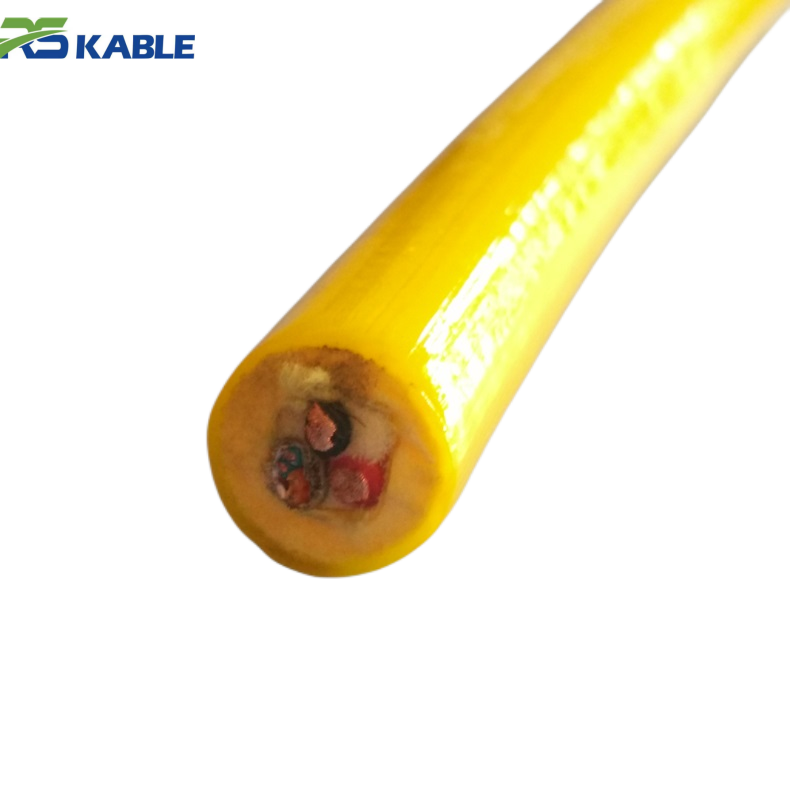

The outer sheath is crafted from a Highly Flexible Elastomer (or PUR/TPU). Unlike standard PVC, this material resists:

- Hydrolysis and Microbes: Won’t break down after prolonged submersion.

- Abrasion: Withstands scraping against ship decks, rocks, or coral.

- Cold Temperatures: Remains flexible and resists cracking in deep-sea freezing conditions.

Technical Specifications

We allow full customization of the internal structure to match your ROV’s power and data requirements.

|

Feature |

Specification Details |

|---|---|

|

Cable Type |

Hybrid Umbilical (Power + Signal + Fiber + Coax) |

|

Rated Voltage |

300V / 600V (Customizable based on application) |

|

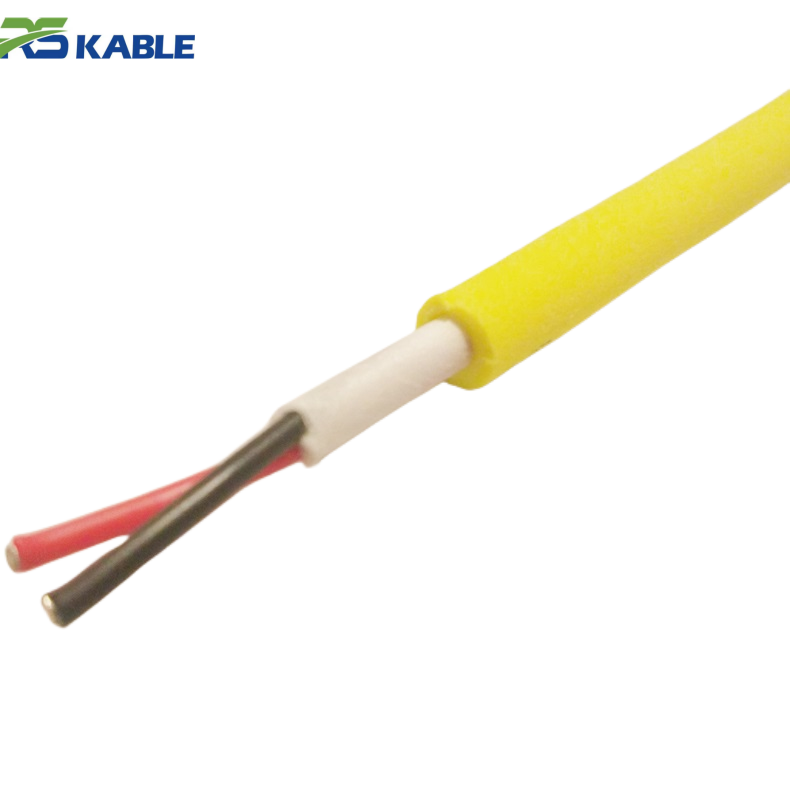

Conductor Material |

Oxygen-free Stranded Copper (High flexibility class) |

|

Insulation Material |

High-Density Polyethylene (PE) or TPE |

|

Outer Sheath |

Saltwater-resistant Polyurethane (PUR) or High-Flex Elastomer |

|

Tensile Member |

Kevlar® Aramid Fiber braiding |

|

Breaking Strength |

Custom: 100kg, 200kg, 500kg, up to 1000kg |

|

Shielding |

Aluminum Foil + Tinned Copper Braid (High coverage >85%) |

|

Optical Fiber |

Single-mode or Multi-mode (1 to 24 cores available) |

|

Power Cores |

Range: 0.5mm² to 6.0mm² (1.0, 1.5, 2.5 common) |

|

Signal Pairs |

Twisted Pair (24AWG / 26AWG) for RS485/RS232 |

|

Depth Rating |

Suitable for Shallow and Deep Sea (Pressure rated designs available) |

|

Operating Temp |

-40°C to +90°C |

Applications

This multi-core hybrid cable is designed for dynamic motion in wet environments:

- Remotely Operated Vehicles (ROV): Main tether or tether management system (TMS) cables.

- Pipe Inspection Robots: Crawlers used in sewage or oil pipelines.

- Oceanographic Instrumentation: Tow cables for sonar and sensors.

- Diving Operations: Umbilicals for diving motors and communications.

- Defense & Military: Submarine systems and unmanned underwater gliders.

Manufacturing & Quality Assurance (E-E-A-T)

Shanghai Rousheng Wire And Cable Co., Ltd. brings years of specialized R&D to the production of complex hybrid cables. Unlike generalist wire suppliers, we focus on high-flex and drag chain applications.

- Customization: We don’t just sell stock. We engineer the cable structure (core count, fiber mode, diameter) to fit your specific connector and winch requirements.

- Testing: All cables undergo rigorous bending, tensile, and insulation resistance testing before shipment.

- Global Export: Trusted by clients in the UAE, Brazil, and Argentina with a focus on reliable delivery and strict quality control.

Frequently Asked Questions (FAQ)

Q: Can you customize the buoyancy of the cable?

A: Yes. We manufacture cables with negative, neutral (zero), or positive buoyancy. For ROVs, we typically recommend neutral buoyancy to minimize drag, which we achieve using specific low-density materials and structural spacing.

Q: What is the Minimum Order Quantity (MOQ) for a custom hybrid design?

A: For standard hybrid structures, our MOQ is typically 100 meters. For highly complex custom designs requiring new extrusion tooling, we can discuss specific batch sizes.

Q: How does the fiber optic element handle bending?

A: Our optical fibers are housed in loose tubes or tight buffers with aramid yarn protection specifically designed to withstand the tight bend radii associated with ROV winches and drums without signal attenuation.

Q: Is this cable suitable for saltwater use?

A: Absolutely. The outer jacket is made from hydrolysis-resistant Polyurethane (PUR) or specialized Elastomer, which is chemically stable in seawater and resists the growth of marine microbes.