Custom High‑Flexibility TPE Insulated 2/3‑Core 0.15/0.2 mm² Robotic Cable

.Custom high‑flex TPE insulated robot cable for dynamic motion systems.

.2/3‑core options with 0.15/0.2 mm² selections for power and control.

.High‑strand copper and TPE jacketing resist wear, oil, and mechanical stress.

.Ideal for robotic arms, drag chain applications, and automated equipment.

.Produced by Shanghai Rousheng — specialized in high‑flex drag chain and specialty cables.

The Custom High‑Flexibility TPE Insulated Robotic Cable is engineered for modern automated systems, including robotic arms, manipulators, and other precision motion devices where strength, dynamic flexibility, and reliability are critical. Featuring multi‑strand copper conductors and a TPE (Thermoplastic Elastomer) jacket, this cable combines mechanical toughness with excellent bend resistance, making it ideal for continuous movement, repeated flexing, and confined motion paths.

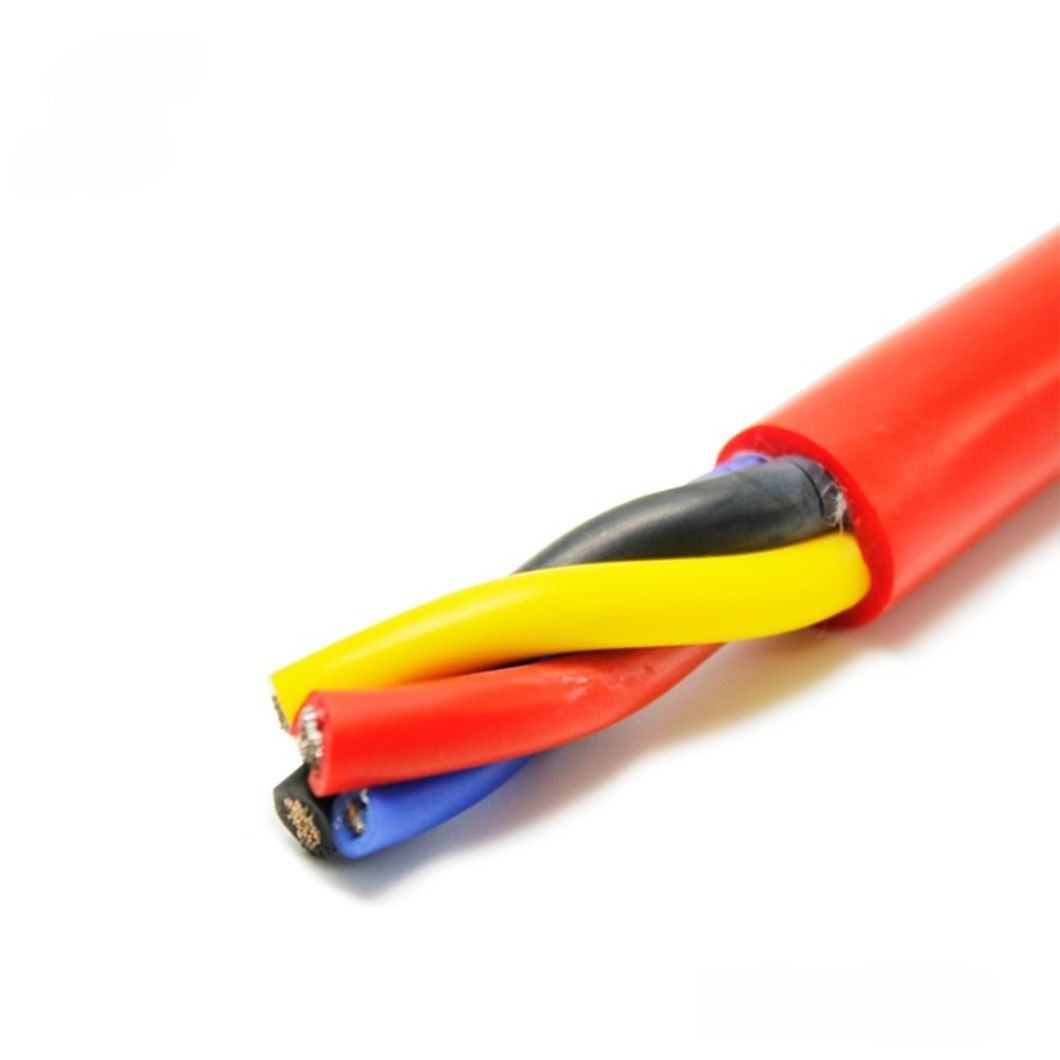

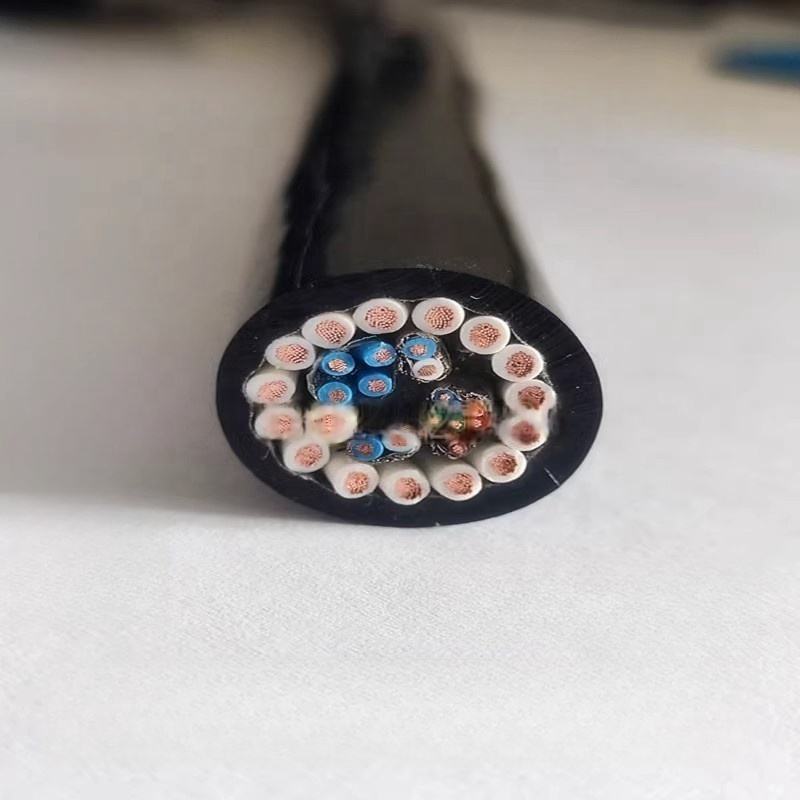

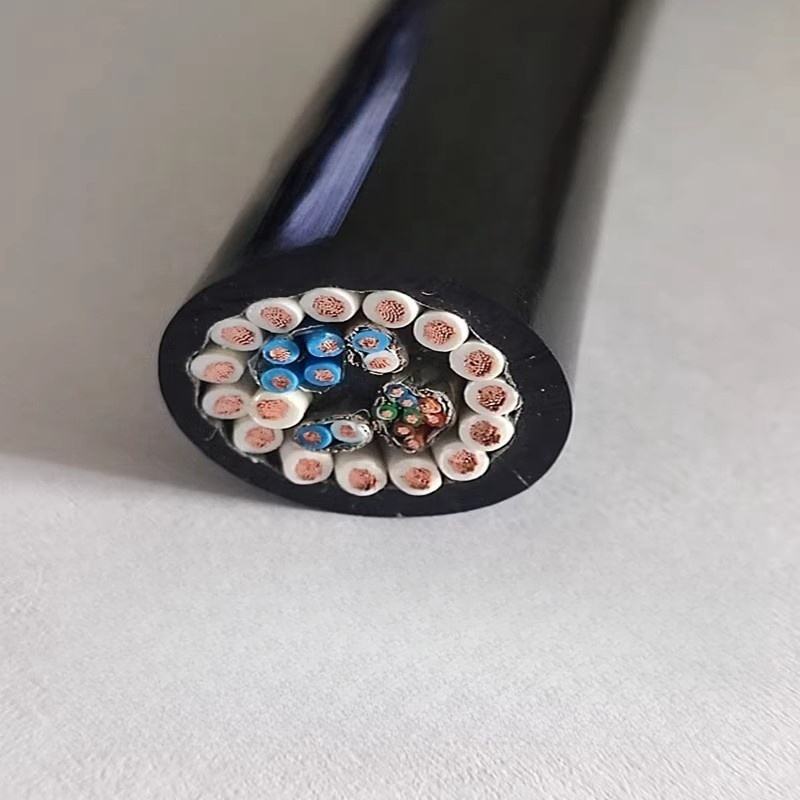

Images above show multi‑core constructions with robust insulation and fill layers designed for mechanical load and motion applications, aligning with what industrial robot cables require.

Why This Cable Matters to You

High Mechanical Performance

-

Built for dynamic motion and drag chain use, this cable tolerates frequent bending and twisting without conductor fatigue.

-

Stranded copper conductors ensure consistent electrical performance even over repeated flex cycles, enhancing long‑term reliability in robotic systems.

TPE Insulation for Tough Environments

-

TPE jacket material delivers excellent resistance to oils, abrasion, wear, and industrial contaminants.

-

Maintains flexibility across wide temperature ranges and resists cracking or stiffness over time.

Compact Yet Powerful Design

-

Supports 2‑core or 3‑core configurations with options for 0.15 mm² or 0.2 mm² conductor sizes to balance mechanical performance and electrical load.

-

Ideal for small to medium power delivery and control signals in robotic systems.

Reliable in Motion

-

Designed to operate reliably in automated environments such as manufacturing lines, machine tools, and robotic arms where cables must withstand constant movement.

Typical Applications

-

Industrial Robot Arms: Power and control wiring in articulated robotic systems.

-

Automated Handling Equipment: Connectors and motion paths where cables bend, twist, and flex frequently.

-

Production & Assembly Lines: Flexible cable routes that require repeated motion without compromising life span.

-

Precision Motion Machinery: Encoders, sensors, and motors in high‑performance mechanical systems.

Technical Specifications

| Feature | Specification |

|---|---|

| Conductor | Stranded Bare Copper |

| Nominal Conductor Size | 0.15 mm² / 0.2 mm² |

| Number of Cores | 2 / 3 |

| Insulation Material | TPE (Thermoplastic Elastomer) |

| Jacket Material | High‑flex TPE |

| Flexibility | High — Suitable for continuous movement |

| Operating Temp Range | ‑40°C to +90°C (typical range) |

| Resistance | Oil, Abrasion, Chemical, Wear |

| Mechanical Stress | Designed for dynamic applications |

| Approvals/Standards | Customizable (IEC, UL, VDE – as required) |

Construction & Material Highlights

Stranded Conductor

Fine‑strand copper bundles deliver exceptional flexibility and fatigue resistance, ideal for robotic motion paths and drag chain routing.

TPE Insulation

Thermoplastic elastomer is chosen for its balance of elasticity and resistance to environmental factors — especially wear and motion stress.

Multi‑Core Assembly

Images show various multi‑core cable structures with internal fillers and protective sheaths to enhance mechanical and electrical performance in complex motion systems.

Customer Value Proposition

-

Enhanced Reliability: Reduces cable failure risks in dynamic robotic systems.

-

Extended Service Life: TPE insulation and flexible conductors resist everyday wear, abrasion, and movement.

-

Customized Solutions: Choose core count, conductor size, and cable length to match your equipment needs.

-

Global Support: Shanghai Rousheng Cable Co., Ltd. provides engineering insight, customization, production, and export services to customers in Europe and over 100 countries.

FAQ — What You Need to Know

Q1: What environments are these robotic cables built for?

A: Designed for continuous flexing, dynamic motion, and mechanical stress, these cables perform reliably in automated, industrial, and robotic arm applications.

Q2: Why choose TPE insulation over PVC?

A: TPE offers better flexibility, abrasion resistance, oil and chemical resistance, and stays soft in low temperature conditions — crucial for dynamic motion uses.

Q3: Can this cable handle repeated bending cycles?

A: Yes — the fine‑stranded copper and TPE jacket are optimized for continuous flex motion and drag chain applications with minimal fatigue.

Q4: Are different specifications available?

A: Yes — you can choose 2 or 3 cores, different conductor cross‑sections, and customized lengths or jacket colors.

Q5: How do I select between 0.15 and 0.2 mm²?

A: 0.15 mm² is often chosen for control/signal wiring with low current; 0.2 mm² supports modest power plus control/signal with a balance of flexibility.