Custom CCTV Pipeline Robot Cable | Copper Conductor PVC Insulation & Polyurethane Jacket for Industrial & Railway Applications

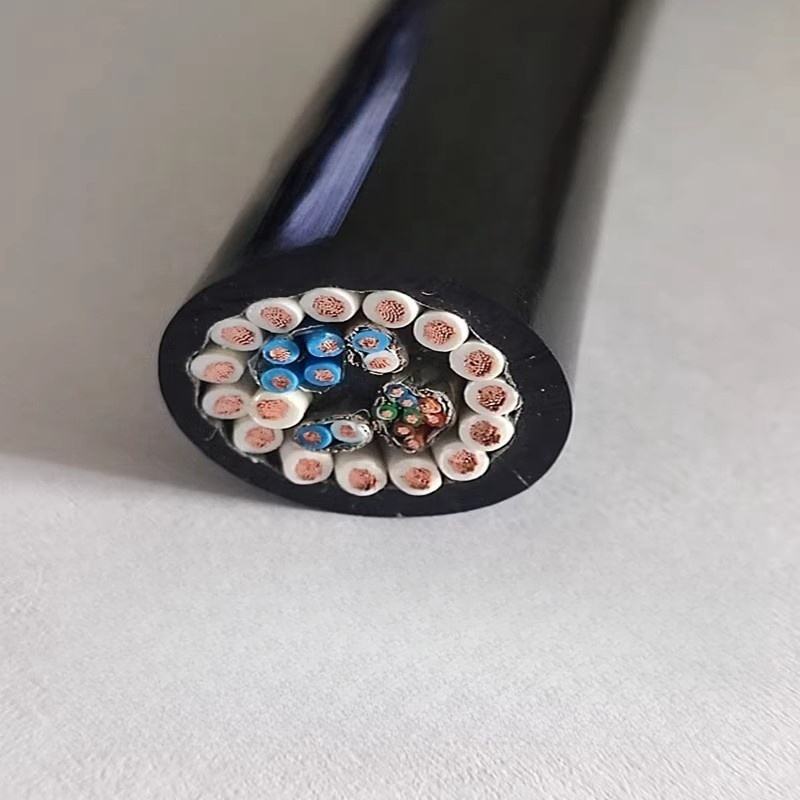

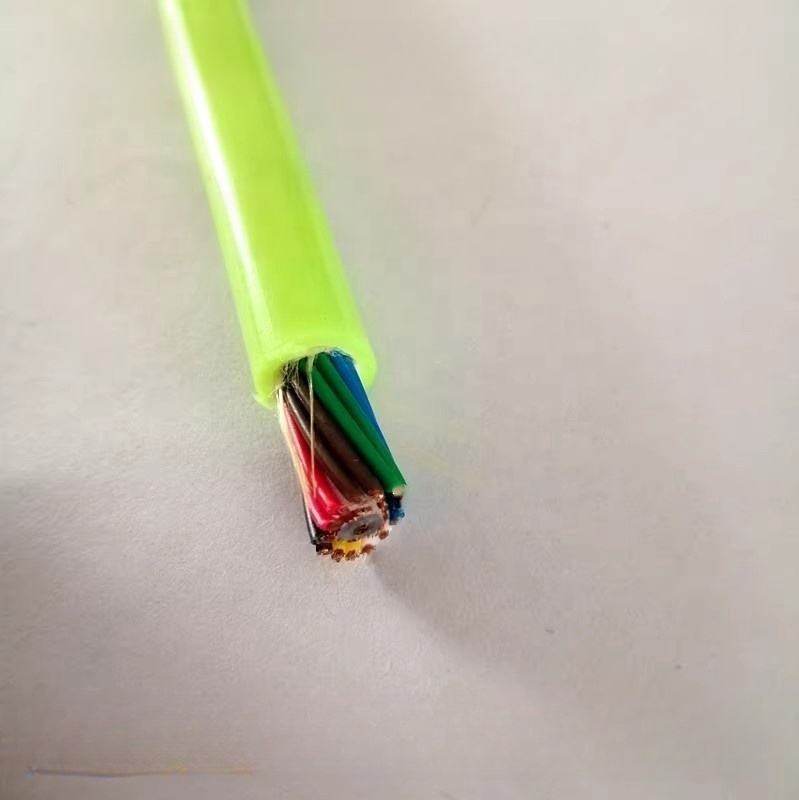

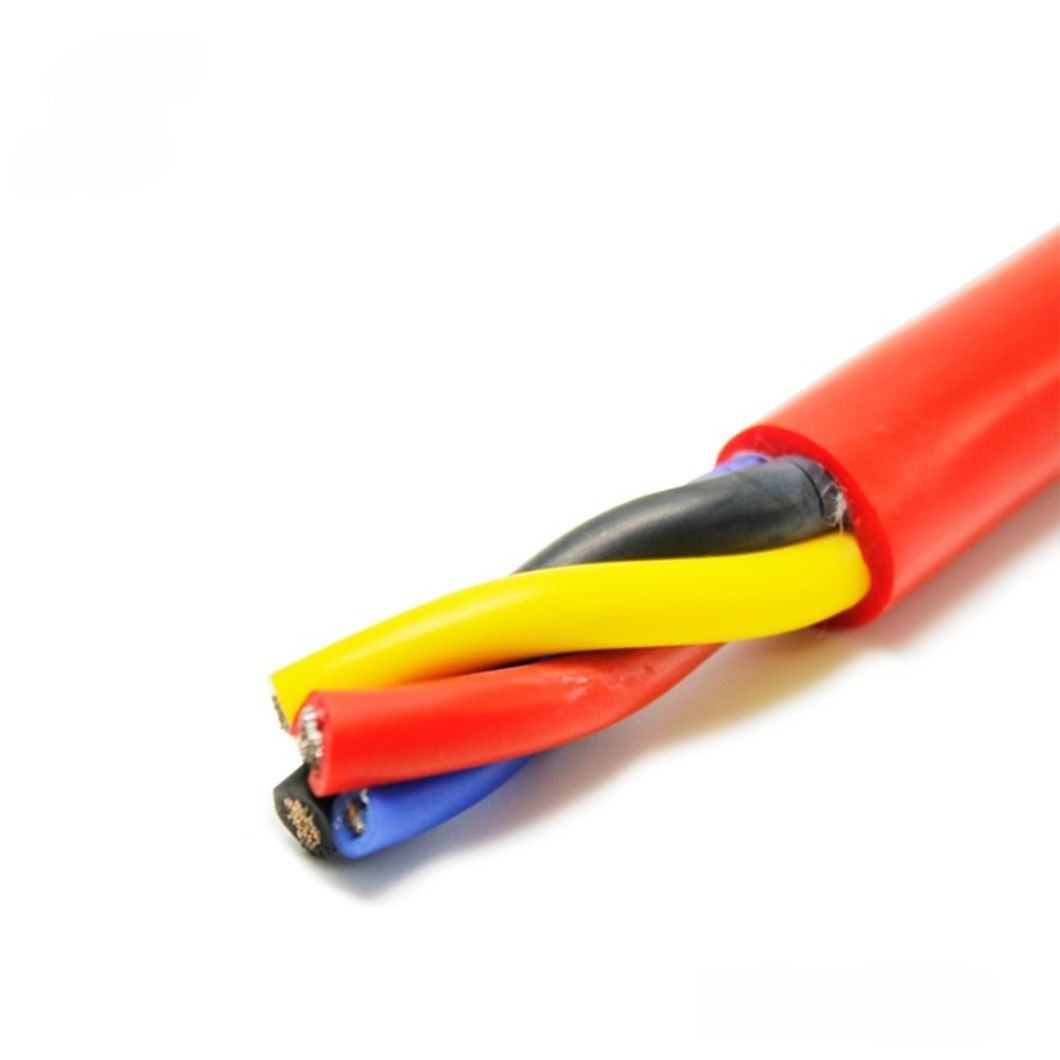

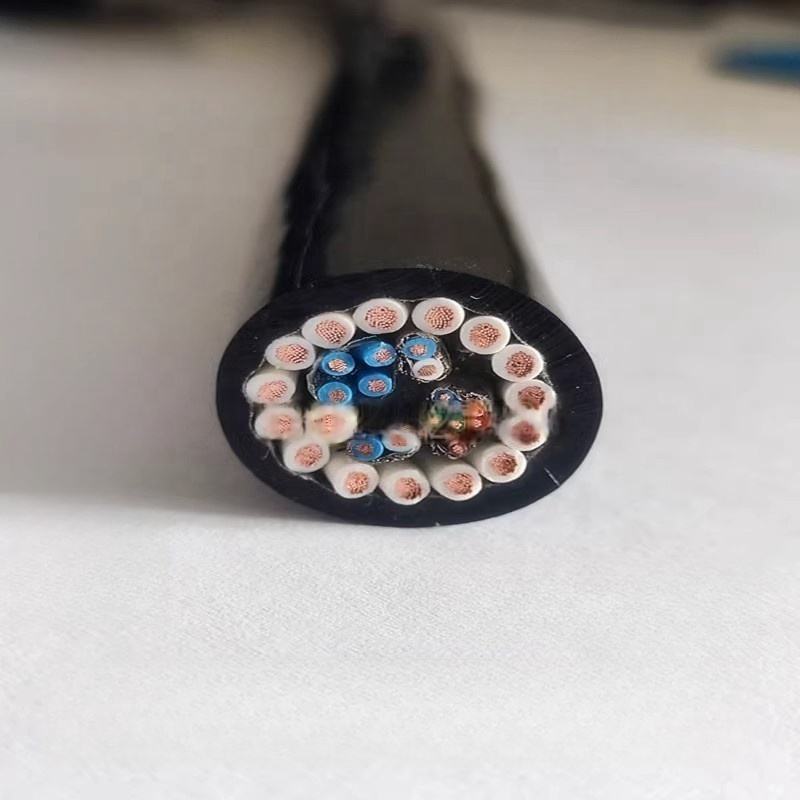

Custom CCTV Pipeline Robot Cable designed for harsh industrial and inspection environments.

Features rugged Polyurethane (PU) jacket for superior abrasion resistance.

High-flex copper conductors ensure durability in drag chain applications.

Resistant to oil, hydrolysis, and temperatures up to 90°C.

Customizable core counts and voltage ratings available.

Custom CCTV Pipeline Robot Cable | Copper Conductor PVC Insulation & Polyurethane Jacket

Engineered for Motion. Built for the Underground.

In the demanding world of industrial inspection and automation, your equipment is only as reliable as its connection. The Custom CCTV Pipeline Robot Cable by Shanghai Ruosheng Wire and Cable Co., Ltd. is engineered specifically for dynamic applications where standard cables fail. Whether you are operating a CCTV sewer crawler, a railway inspection bot, or a drag chain system, this cable delivers uncompromised power and data transmission.

Why Choose Ruosheng High-Flexible Robot Cables?

We don’t just sell cables; we engineer solutions for motion. With over 100 varieties of special cables developed, we understand the physics of drag and flex.

- Ultimate Abrasion Resistance: The outer Polyurethane (PU) jacket is chemically formulated to resist the harsh grinding of concrete pipes, sharp metal edges, and industrial debris. It significantly outlasts standard PVC in abrasive environments.

- High-Flex Life: Featuring fine-stranded Copper Conductors, this cable maintains conductivity even after thousands of bending cycles, making it perfect for drag chains and robotic arms.

- Harsh Environment Ready: Resistant to hydrolysis, microbes, oils, and industrial coolants. Rated for working temperatures up to 90°C.

- Signal Clarity: High-quality insulation ensures your video feed remains crisp and interference-free, critical for precise pipeline defect analysis.

Technical Specifications

|

Feature |

Specification |

|---|---|

|

Conductor Material |

High-Purity Stranded Copper (Class 5/6 Flexibility) |

|

Insulation |

Premium PVC (Polyvinyl Chloride) |

|

Jacket Material |

PUR (Polyurethane) – Abrasion & Oil Resistant |

|

Voltage Rating |

Available in 300V, 500V, 600V, 750V |

|

Temperature Range |

-20°C to +90°C (Dynamic application) |

|

Core Configuration |

Custom (6, 8, 10, 12, 102 cores available) |

|

Applications |

Pipeline Crawlers, CCTV Inspection, Railway Systems, Drag Chains |

|

Certifications |

CE, RoHS Compliant |

Engineered for Your Specific Application

- Sewer & Pipeline Inspection: The anti-friction PU jacket allows the cable to slide smoothly over wet, rough surfaces without snagging or tearing.

- Railway & Transport: Resistant to vibration and temperature fluctuations common in rail infrastructure maintenance.

- Industrial Automation: Ideal for power distribution in moving machinery where space is tight and flexibility is non-negotiable.

Frequently Asked Questions (FAQ)

Q: Can this cable be used underwater?

A: Yes, the Polyurethane jacket offers excellent hydrolysis resistance, making it suitable for damp and wet environments often found in pipeline inspection. For deep submersion requirements, please consult our engineering team for specific depth ratings.

Q: What is the Minimum Order Quantity (MOQ) for custom sizes?

A: We support your growth. For standard customized variations, we offer flexible MOQs. Please contact us with your specific core count and length requirements for a tailored quote.

Q: How does the PU jacket differ from standard PVC?

A: PU (Polyurethane) is mechanically tougher than PVC. It offers superior cut resistance, flexibility at low temperatures, and longer life in dynamic “drag” applications, reducing the frequency of cable replacement.

Q: Do you offer shielded versions for interference protection?

A: Yes, we can manufacture this cable with tinned copper braiding or aluminum foil shielding to protect sensitive video and data signals from electromagnetic interference (EMI).