Control Cable for Multi‑Axis & Multi‑Joint Robot Systems | Automated Handling & Installation Robotics Cable

Control Cable for Multi‑Axis & Multi‑Joint Robot Systems.

.Designed for 3D torsional stress up to ±360°/m

.High-abrasion PUR jacket for oil & coolant resistance

.Class 6 super-fine copper stranding prevents breakage

.Ideal for 6-axis robots and automated handling systems

.CE & RoHS compliant for global export standards

Downtime is the silent budget killer in modern manufacturing. When a multi-axis robot fails, it’s rarely the motor or the software that gives up first—it’s usually the cable.

Standard “flexible” cables aren’t built for the complex, 3D movements of 6-axis robots or automated handling systems. They might survive the initial installation, but subjected to constant torsion and twisting, the copper inside work-hardens and snaps, or the jacket cracks from abrasion.

At Shanghai Rousheng Wire & Cable, we engineer cabling solutions specifically for these high-stress environments. Our control cables for multi-axis robots are designed to withstand millions of torsional cycles, ensuring your automated installation lines stay running without unexpected interruptions.

The Engineering Behind Torsion-Resistant Cables

Robotics applications differ fundamentally from standard drag chain applications. In a linear drag chain, a cable only needs to bend back and forth. In a multi-joint robot, the cable is twisted, pulled, and bent simultaneously.

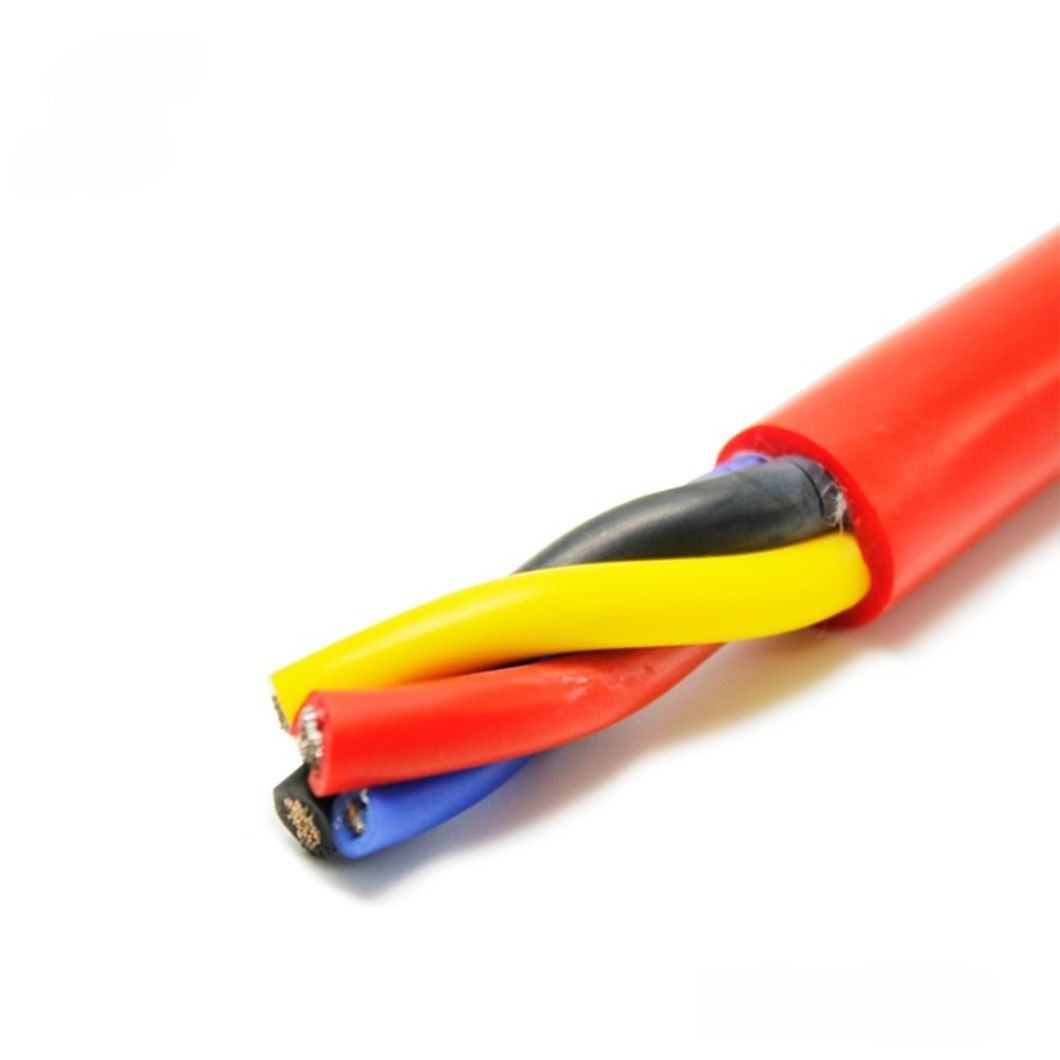

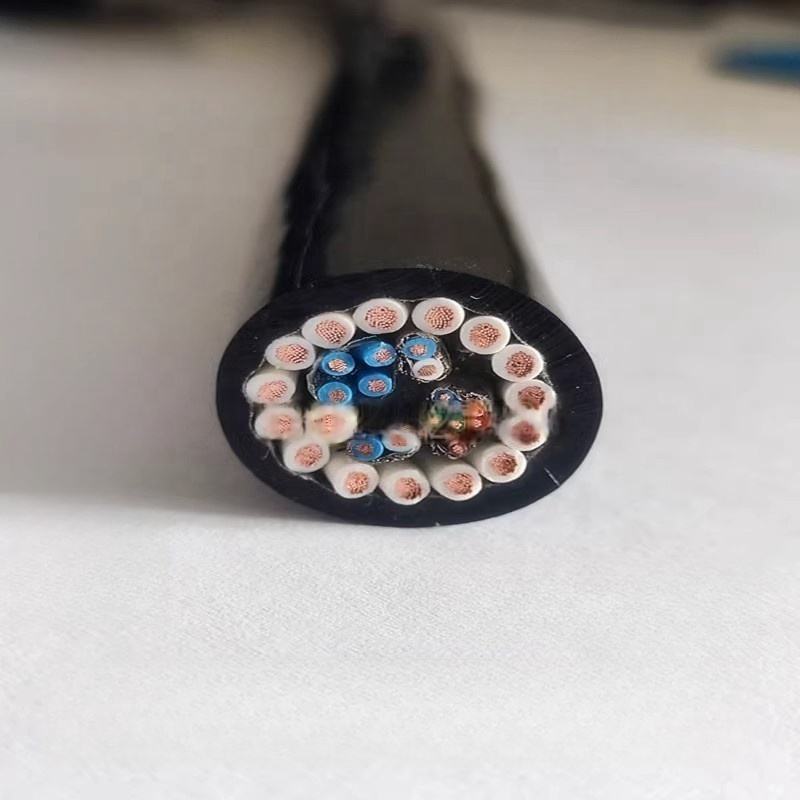

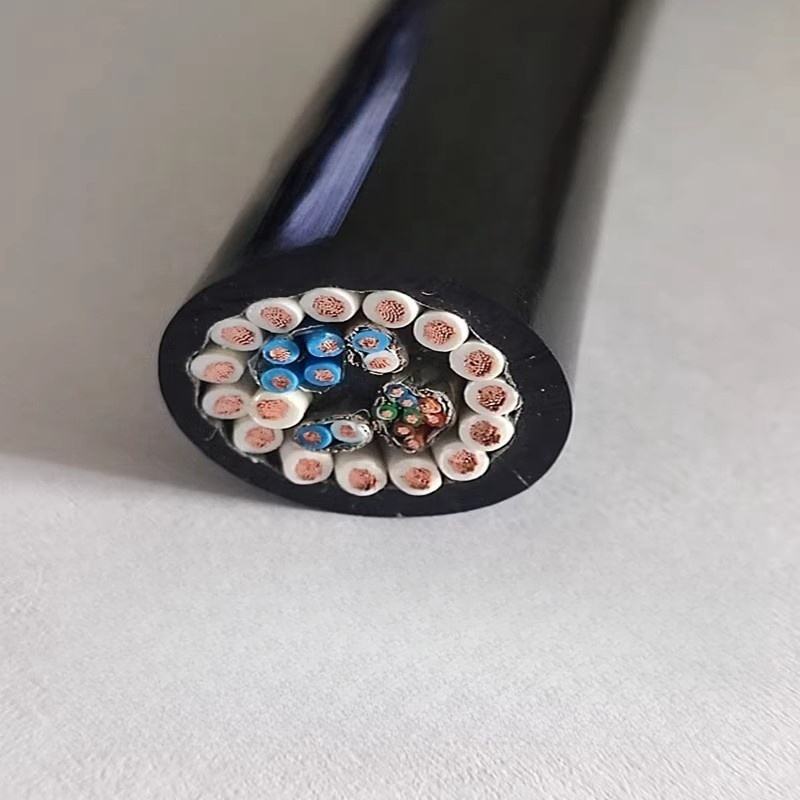

To handle this 3D stress, we use a distinct internal structure:

- Class 6 Super-Fine Stranding: Instead of standard coarse strands, we use ultra-fine copper bundles. These bundles flow over each other like water during movement, preventing the “corkscrewing” effect that destroys lesser cables.

- Slip Plane Technology: We incorporate specific low-friction fleece materials between the conductors and the outer jacket. This allows the internal core to rotate independently from the outer sheath, reducing internal heat and mechanical strain.

- Torsion-Optimized Shielding: Standard braided shields will tear apart under constant twisting. Our cables utilize a specialized spiral or optimized braid angle that expands and contracts with the robot’s movement, maintaining EMC protection without mechanical failure.

Material Matters: PUR vs. TPE

The outer jacket is your first line of defense against the harsh factory floor environment.

- PUR (Polyurethane): The gold standard for machine tools and robotics. It offers exceptional resistance to mineral oils, coolants, and abrasion. If your robot operates in a machining center with cutting fluids, PUR is the necessary choice.

- TPE (Thermoplastic Elastomer): Offers excellent flexibility and low-temperature performance, making it ideal for high-speed pick-and-place applications or cleanroom environments.

Our range covers both options, ensuring you have the right protection for your specific chemical and mechanical environment.

Applications and Industry Use Cases

Our multi-axis control cables are currently deployed across 100+ countries, serving industries where precision and reliability are non-negotiable.

- Automotive Assembly: Welding and painting robots requiring high-torsion power and control feeds.

- Material Handling: Automated palletizing and pick-and-place systems.

- Machine Tools: Multi-axis CNC machines where cables are exposed to coolant and sharp chips.

- Packaging Systems: High-speed pharmaceutical and food packaging lines.

Technical Specifications

Below are the typical specifications for our high-flex robot control series. Please refer to specific datasheets for exact model parameters.

|

Feature |

Specification |

|---|---|

|

Conductor |

Super-fine bare copper strands, Class 6 (VDE 0295 / IEC 60228) |

|

Insulation |

High-mechanical TPE or specialized PP for low capacitance |

|

Outer Jacket |

PUR (Polyurethane) – Halogen Free, Flame Retardant |

|

Torsion Rating |

Up to ±360° per meter (depending on model) |

|

Minimum Bending Radius |

Moving: 7.5x to 10x Cable Diameter |

|

Temperature Range |

Moving: -25°C to +80°C (Fixed: -40°C to +80°C) |

|

Nominal Voltage |

300/500V (Control) or 600/1000V (Power) |

|

Oil Resistance |

Excellent (acc. to DIN EN 50363-10-2) |

|

Certifications |

CE, RoHS, REACH, UL Styles (upon request) |

Frequently Asked Questions (FAQ)

Q: Can I use a standard drag chain cable for a 6-axis robot?

A: Generally, no. Standard drag chain cables are designed for linear bending (rolling flex). They are not designed to handle the twisting forces (torsional flex) of a 3D robot arm. Using a linear cable in a torsion application will likely lead to premature failure.

Q: What is the service life of these cables?

A: While lifespan depends on the specific bend radius, speed, and installation quality, our cables are engineered for millions of cycles. In standard lab tests, our high-flex series consistently outperforms standard control cables by a factor of 10 in dynamic applications.

Q: Do you offer custom lengths or connectorization?

A: Yes. Shanghai Rousheng specializes in customized solutions. We can provide cables cut to specific lengths or fully assembled “ready-to-connect” harnesses to speed up your installation time.

Q: Why is PUR preferred over PVC for robotics?

A: PVC has high surface friction and can stiffen or crack over time when exposed to oil. PUR is mechanically tougher, “slipperier” (low friction), and maintains flexibility longer, which is critical for the high speeds of modern robotics.

Why Partner with Shanghai Rousheng?

Since our inception, Shanghai Rousheng Wire & Cable Co., Ltd. has focused on one thing: mastering cable flexibility. We don’t just sell wire; we engineer movement. With over 100 varieties of special cables and a dedication to R&D, we bridge the gap between European quality standards and cost-effective manufacturing. Whether you are building a new automated cell or retrofitting an existing line, our team ensures your power and data delivery remains uninterrupted.