AUV & UUV Applications | Neutral Buoyancy Cable | Neutral Buoyancy Control | Lightweight Jacket, Low Drag

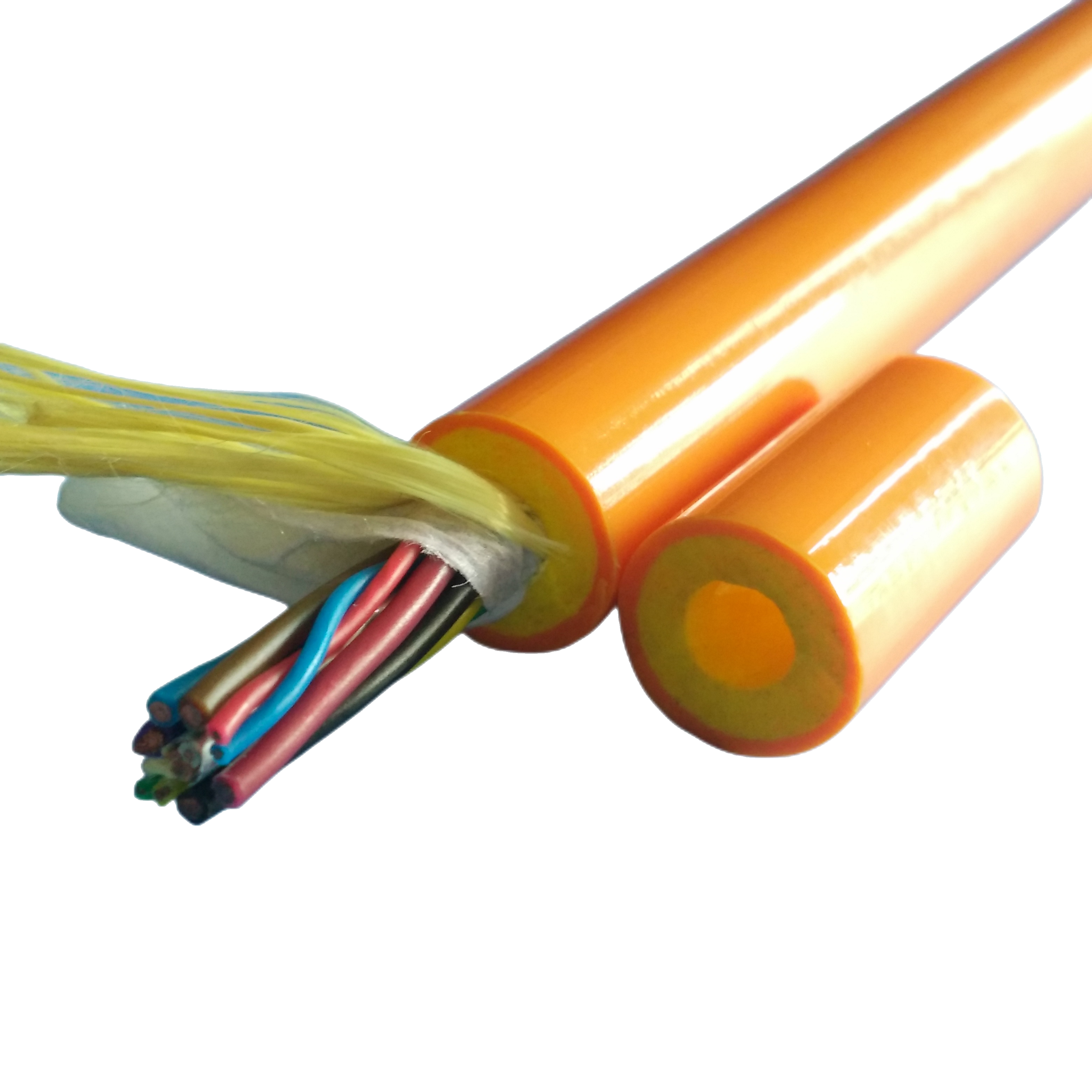

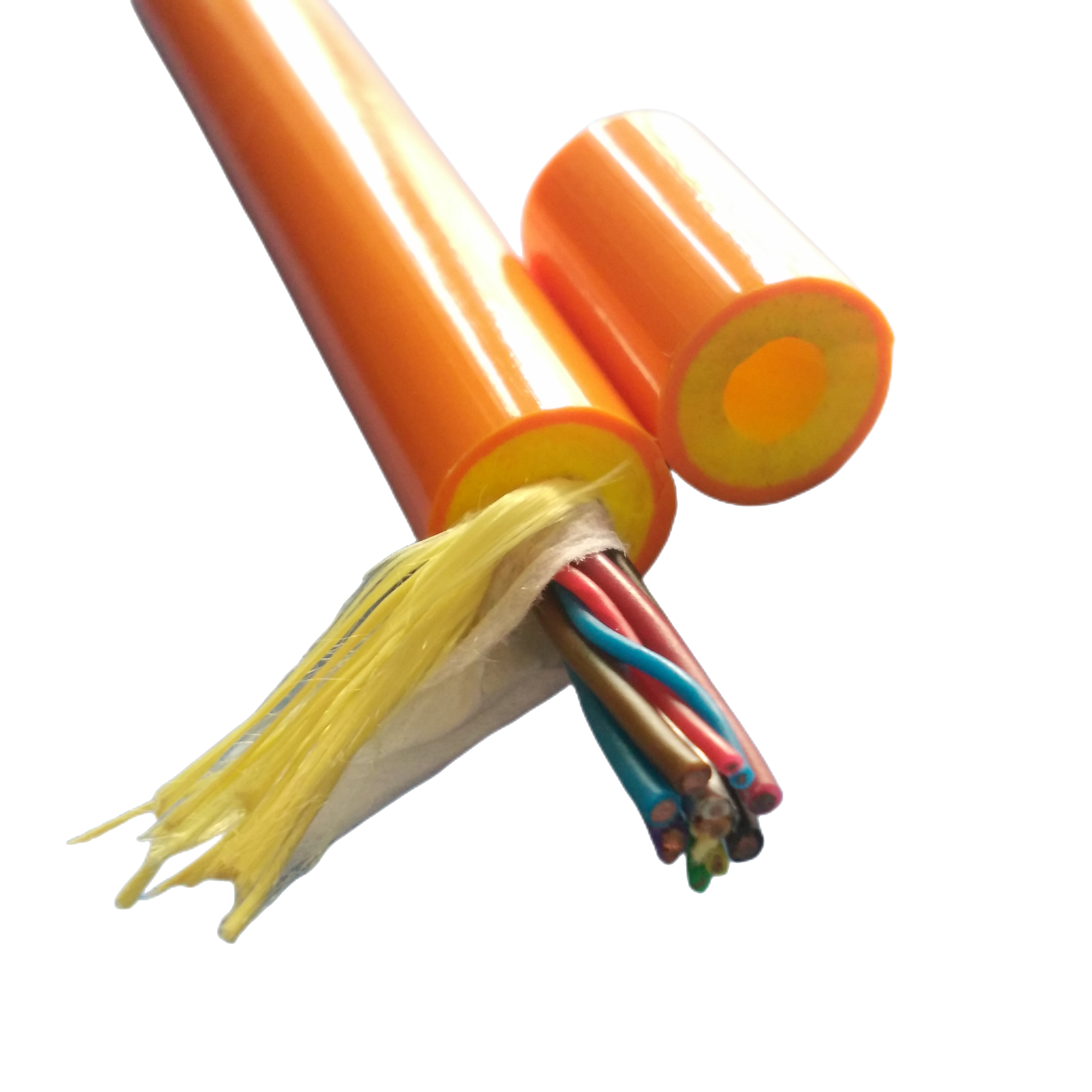

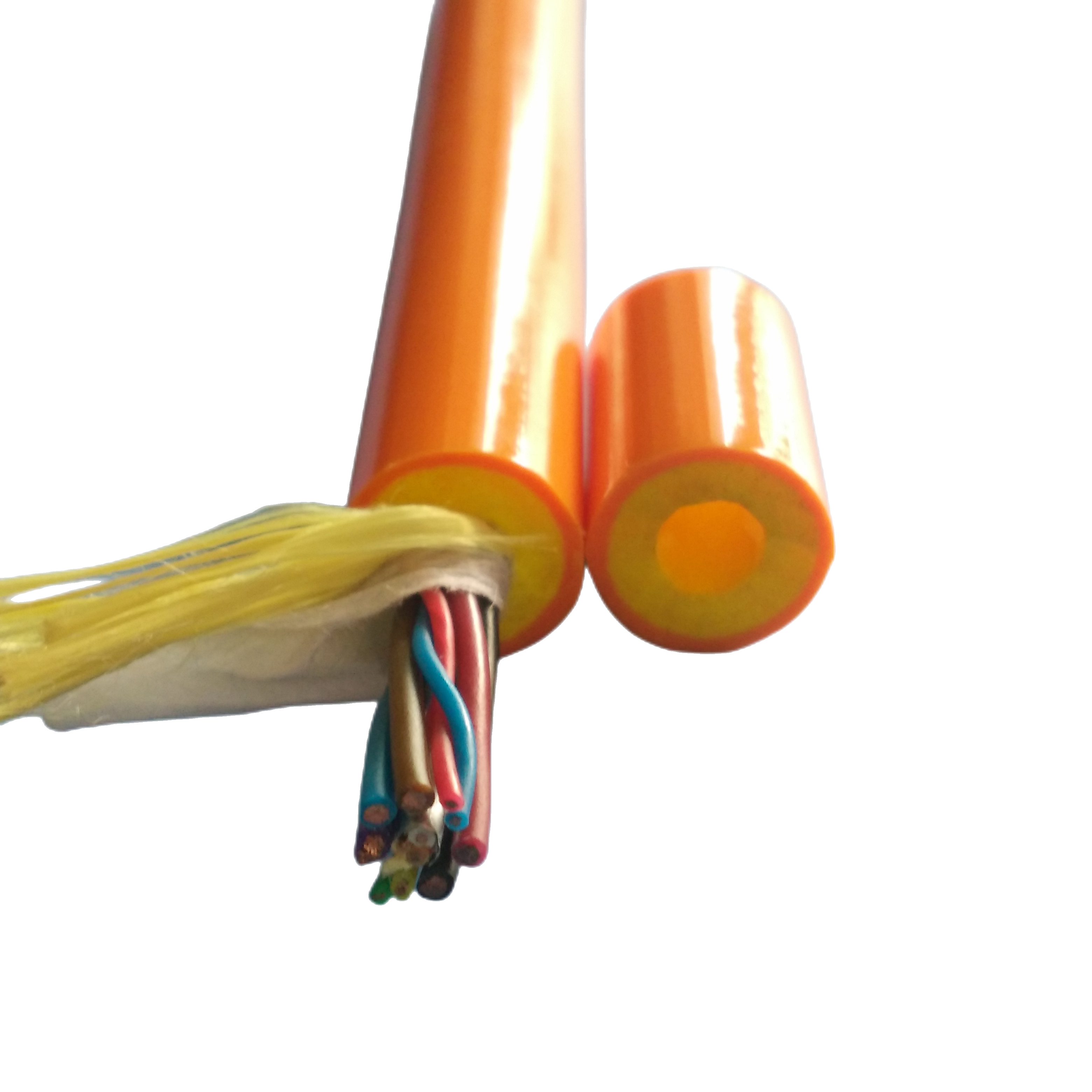

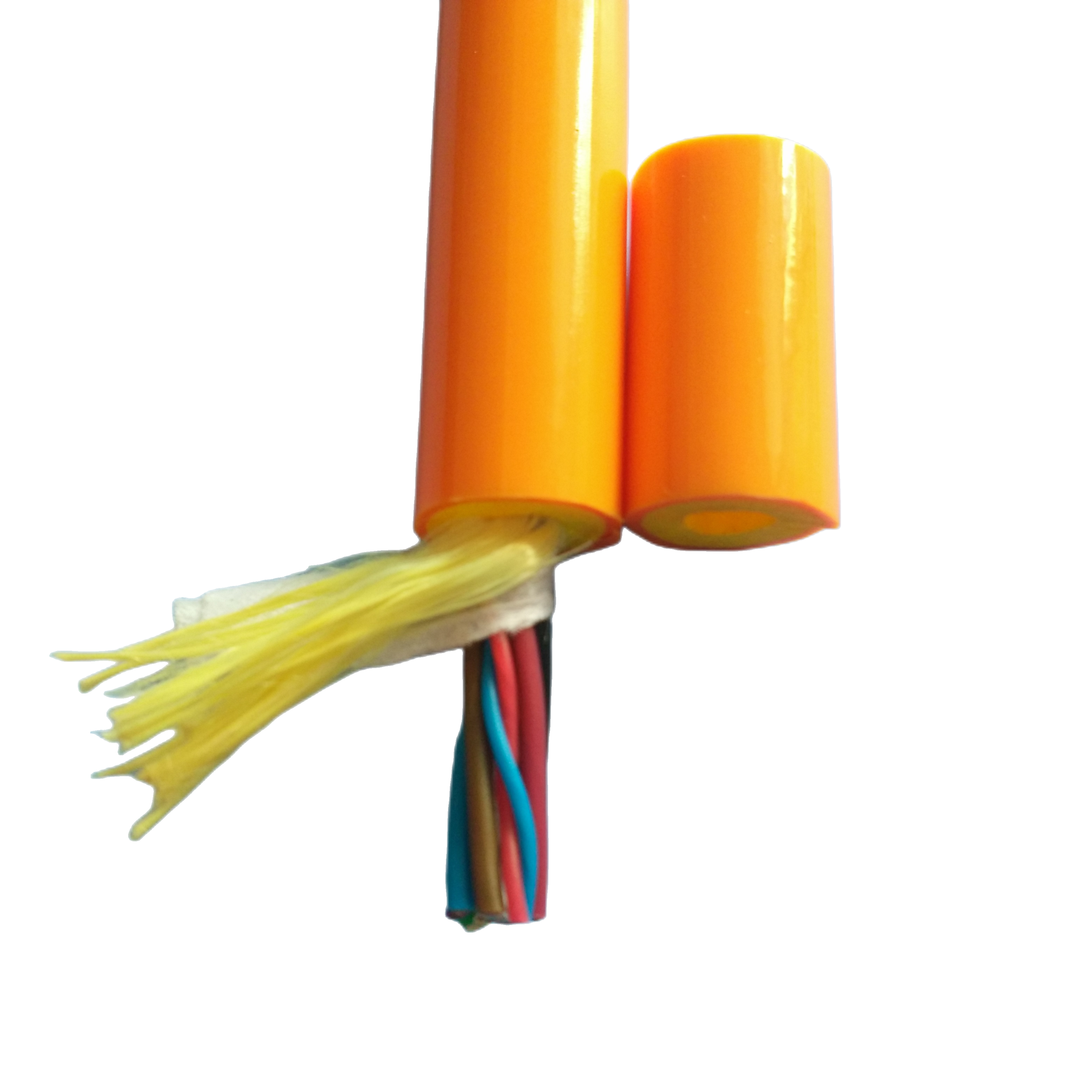

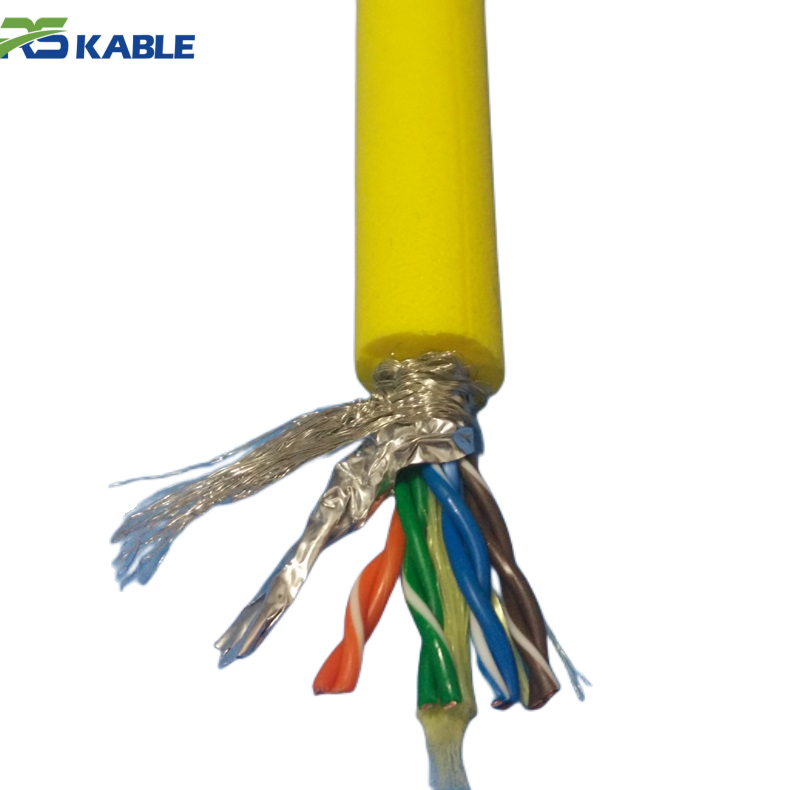

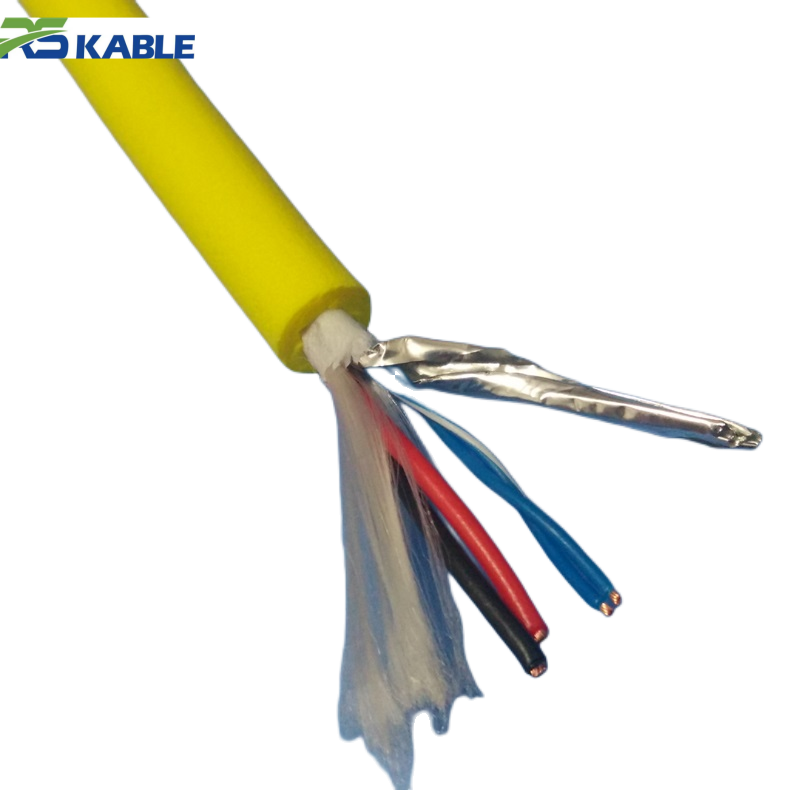

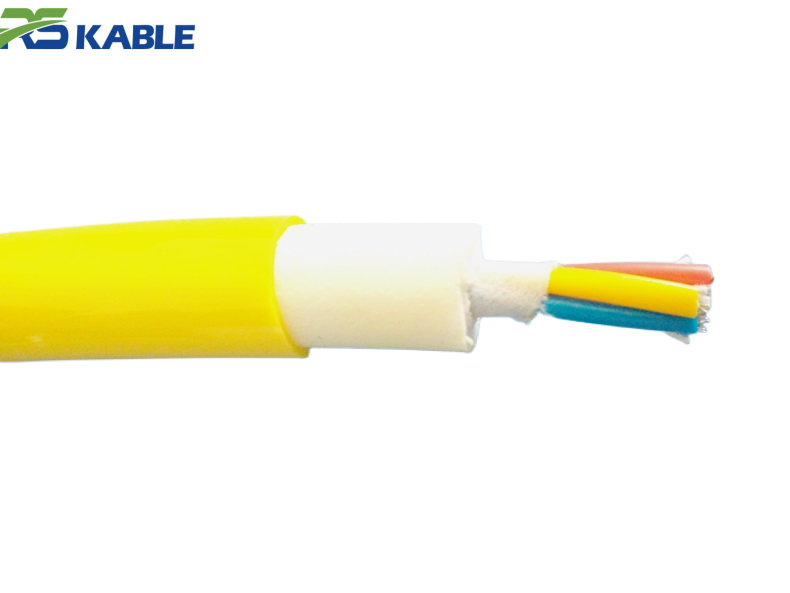

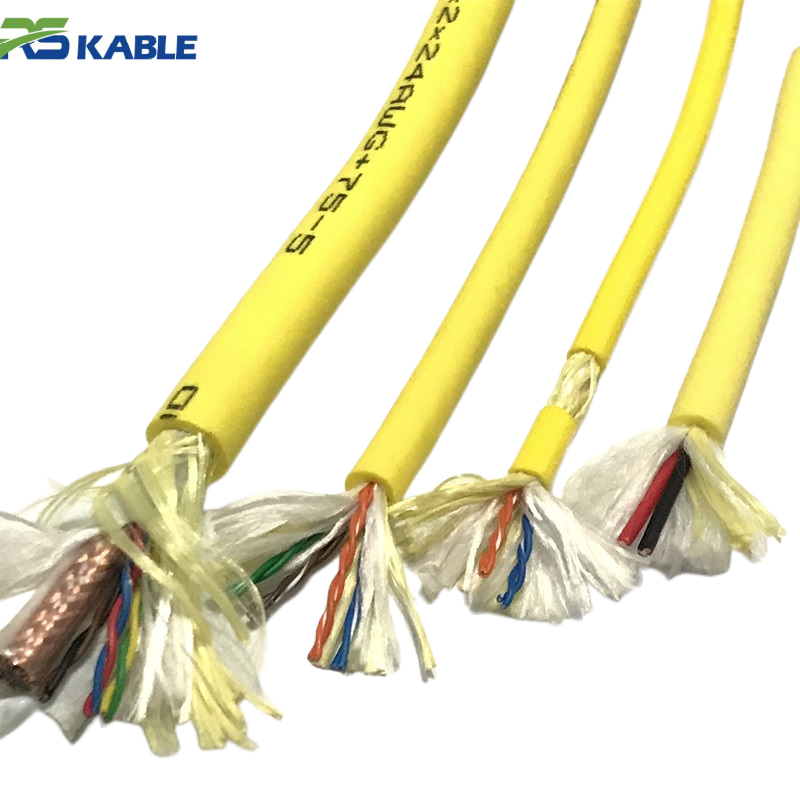

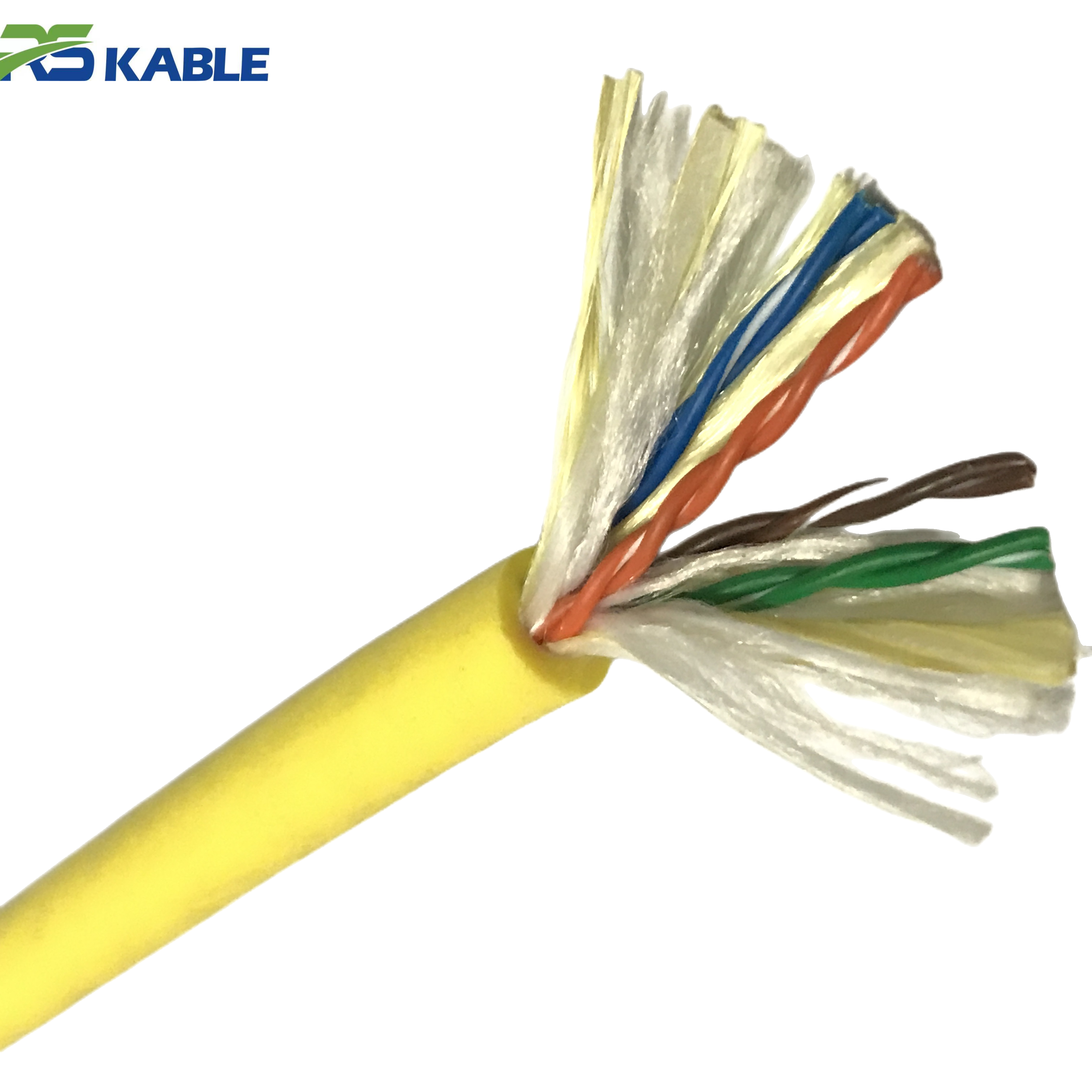

• Conductor: Ultra-fine stranded tinned copper with optimized cross-section for minimal weight and maximum conductivity in power-limited autonomous systems.

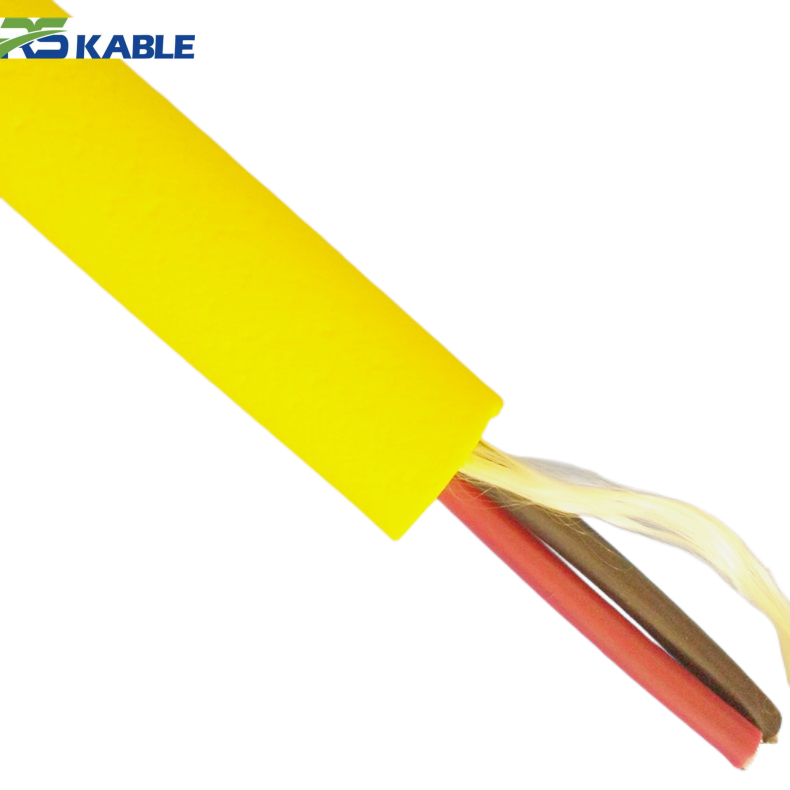

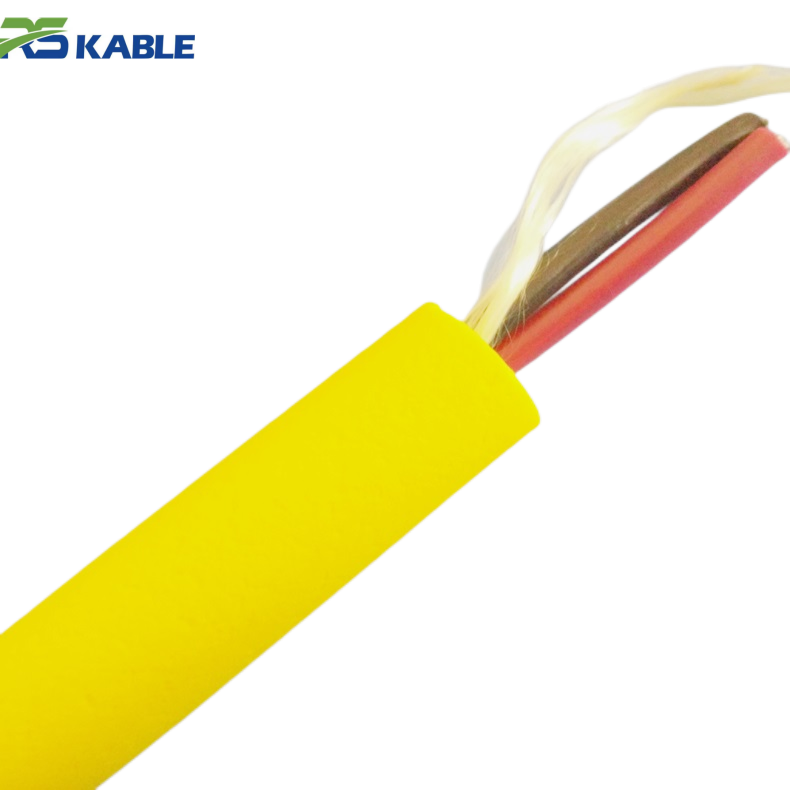

- Jacket: Ultra-lightweight low-drag thermoplastic compound with hydrodynamic matte finish, reducing water resistance and overall tether mass.

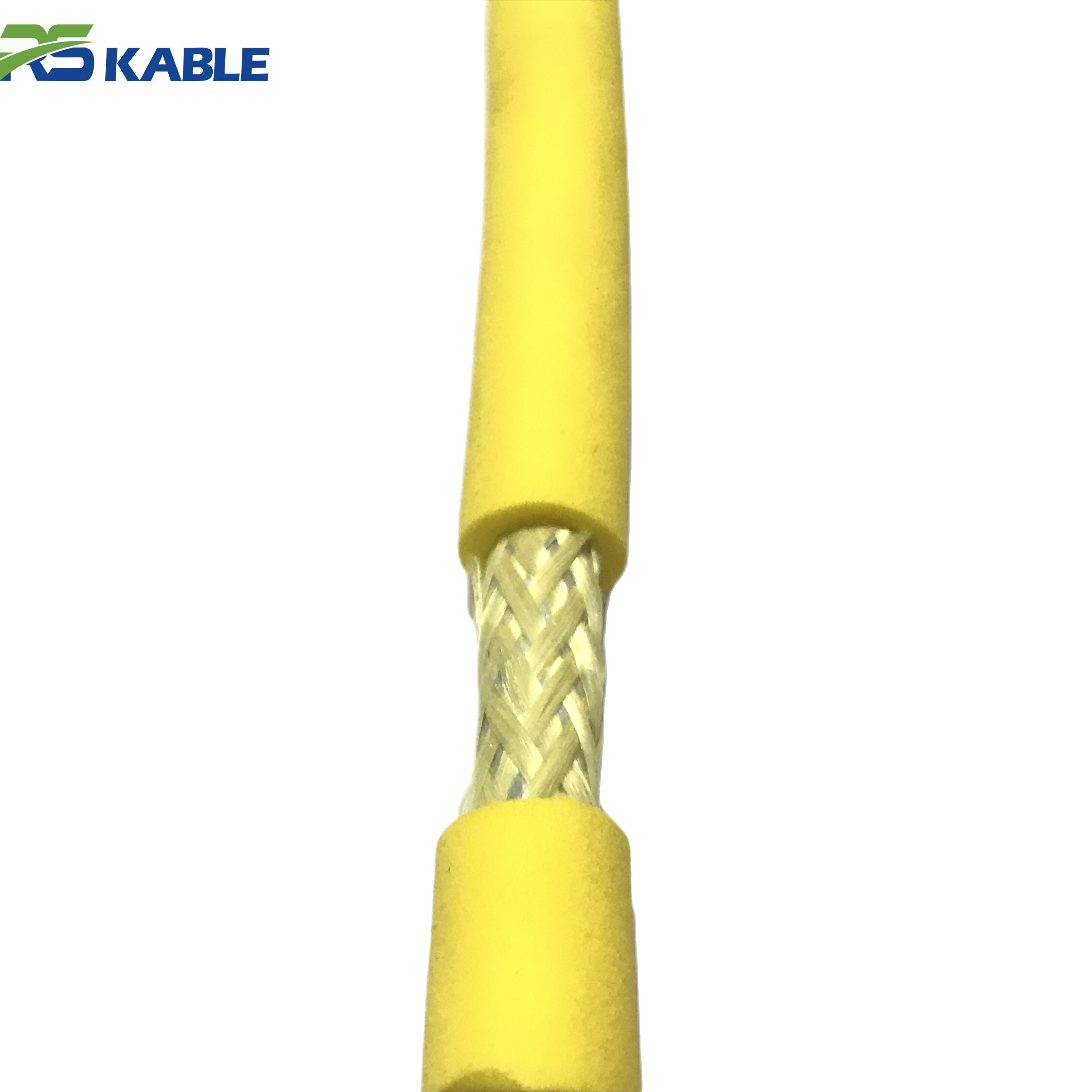

- Structure: Precision foamed insulation combined with high-performance synthetic strength members for exact neutral buoyancy control and compact stowage.

- Performance: Exceptional flexibility with bend radius as low as 5–7x OD, enabling extended mission endurance and energy-efficient operation.

- Environment: Fully optimized for AUV/UUV deployments in varying salinity and temperatures, with low-drag profile supporting long-range autonomous missions up to 6,000+ meters.

AUV & UUV Applications | Neutral Buoyancy Cable | Neutral Buoyancy Control | Lightweight Jacket, Low Drag

Power your autonomous underwater missions with our precision-engineered Neutral Buoyancy Cable—the ideal tether for AUV and UUV platforms requiring exact neutral buoyancy control. Featuring a lightweight jacket, low-drag profile, and multi-stranded conductors, this cable minimizes hydrodynamic resistance while delivering reliable power, high-bandwidth data, and control links for extended-range, energy-efficient operations.

With over 22 years of experience in autonomous underwater vehicle cabling and partnerships with leading AUV/UUV manufacturers worldwide, our solutions are field-proven and manufactured under ISO 9001:2015 certified processes, fully RoHS and REACH compliant, and optionally verified by ABS, DNV-GL, or Bureau Veritas.

Why Choose Our Neutral Buoyancy Cable for AUV & UUV Missions

For AUVs and UUVs, every gram and watt matters. Our Neutral Buoyancy Cable ensures precise buoyancy, lightweight construction, and low-drag performance, enabling longer missions, higher energy efficiency, and reduced thruster load.

Key benefits:

-

Exact neutral buoyancy control: material density calibrated to 1.00–1.02 g/cm³ in seawater

-

Ultra-lightweight jacket: reduces tether weight by up to 30% compared to traditional designs

-

Hydrodynamic low-drag profile: smooth surface minimizes water resistance

-

High-strength synthetic reinforcement: superior strength-to-weight ratio

-

Flexible design: compact stowage and deployment for small vehicles

-

Stable electrical & optical performance: supports wide temperature and pressure ranges

Product Models & Core Attributes

| Model | Core Attributes | Conductor / Fiber Configuration | Rated Depth | Outer Diameter | Weight in Air (per m) |

|---|---|---|---|---|---|

| NB-AUV-4L | 4-core power, low-drag, neutral control | 4 × 1.0 mm² tinned copper | 4,000 m | 14.2 mm | ≤ 180 g |

| NB-AUV-6HY | 6-core hybrid, ultra-light jacket, high bandwidth | 4 × 1.5 mm² + 2 × twisted pair + 2 fibers | 5,000 m | 17.8 mm | ≤ 240 g |

| NB-UUV-8FO | 8-channel fiber-dominant, minimal drag | 2 × 2.0 mm² + 6–12 fiber elements | 6,000 m | 19.5 mm | ≤ 280 g |

| NB-AUV-PRO | Professional-grade, enhanced lightweight armor | 6 × 1.5 mm² + multi-pair + fiber options | 6,000 m | 21.3 mm | ≤ 320 g |

All models use advanced lightweight thermoplastic or composite jackets optimized for low drag and precise neutral buoyancy.

Applications & Mission Scenarios

Our Neutral Buoyancy Cable supports AUV and UUV operations where autonomy, endurance, and efficiency are critical:

-

Long-endurance oceanographic surveys and seafloor mapping

-

Persistent environmental monitoring and water column profiling

-

Military UUV missions (ISR, reconnaissance)

-

Pipeline and subsea cable inspections with minimal energy use

-

Glider augmentation and hybrid propulsion systems

-

Deep-water resource exploration and habitat studies

Long-tail SEO phrases: neutral buoyancy cable for AUV long endurance missions, low-drag tether for UUV autonomous operations, lightweight neutral buoyancy cable for 6000m AUV deployments.

Technical Specifications

| Parameter | Specification | Standard / Notes |

|---|---|---|

| Conductor | Fine-stranded tinned copper (Class 6 ultra-flex) | IEC 60228 |

| Insulation | Lightweight foamed thermoplastic | Optimized for neutral buoyancy and low weight |

| Strength Member | High-performance synthetic fibers (Dyneema® equivalent) | Strength-to-weight ratio >10:1 |

| Shielding | Overall braid + individual pair shields (≥90% coverage) | Low EMI for clean sensor/data signals |

| Outer Jacket | Lightweight low-drag thermoplastic | Hydrodynamic, UV stabilized, seawater-resistant |

| Buoyancy Control | Factory-calibrated neutral (±0.02 g/cm³ tolerance) | Customizable for salinity and temperature |

| Operating Temperature | –35°C to +75°C (submerged) | Wide operational envelope |

| Voltage Rating | 300/600V standard (1 kV options available) | Efficient power transfer |

| Certifications | ISO 9001:2015, RoHS, REACH, optional ABS/DNV | Independently validated |

Frequently Asked Questions (FAQ)

Q: How does the lightweight jacket improve AUV/UUV performance?

A: Reduces tether mass and hydrodynamic drag, extending mission range and lowering energy consumption.

Q: Can buoyancy be precisely tuned?

A: Yes. Factory calibration achieves exact neutral buoyancy for salinity, temperature, and depth.

Q: Is the cable suitable for fully untethered AUVs?

A: While designed for tethered/hybrid modes, its low weight and compact design suit docking umbilicals and recoverable tethers.

Q: Are fiber optic telemetry options available?

A: Yes. Single-mode or multi-mode fibers support high-bandwidth sonar, video, and sensor data.

Q: How is long-term reliability ensured?

A: Through accelerated life testing (flex, pressure, temperature cycling) and proven materials used in multi-year deployments.