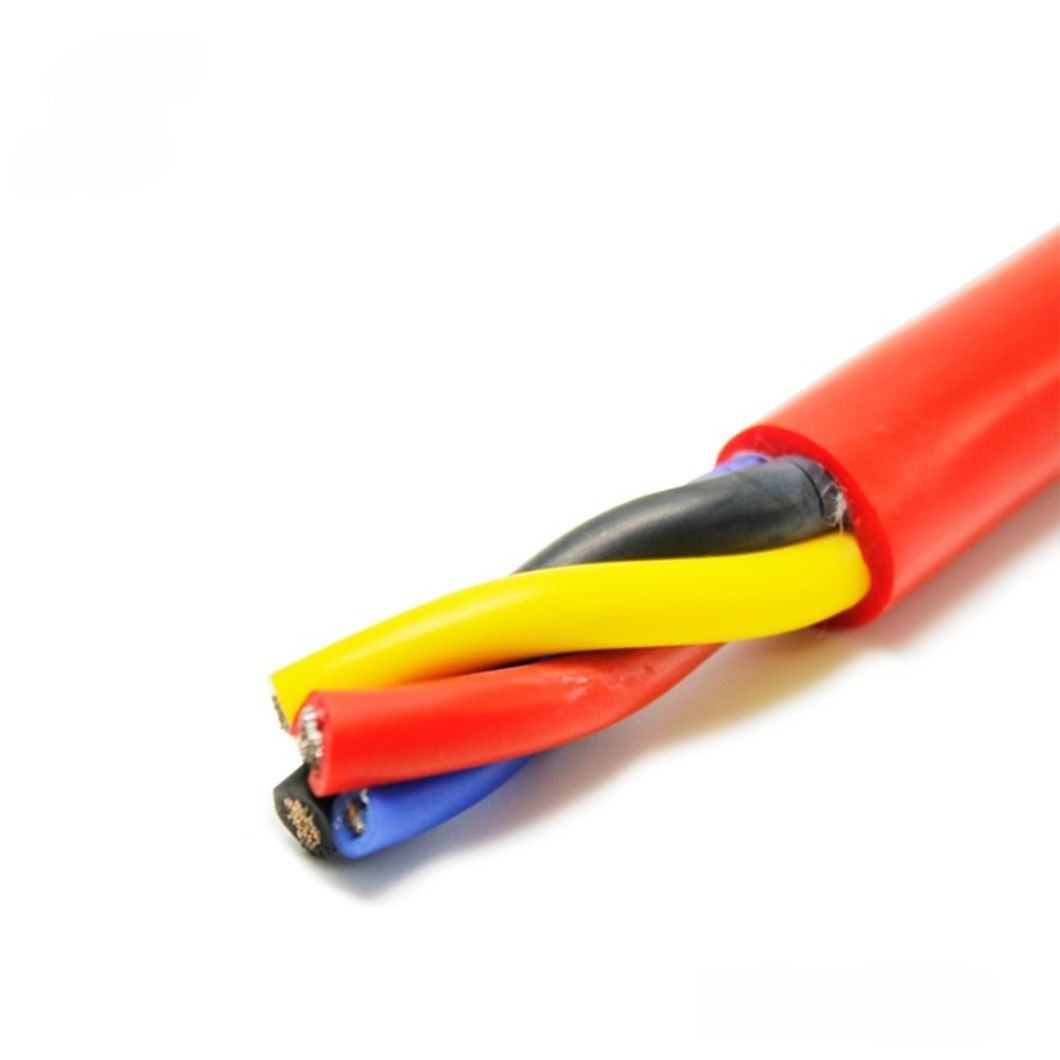

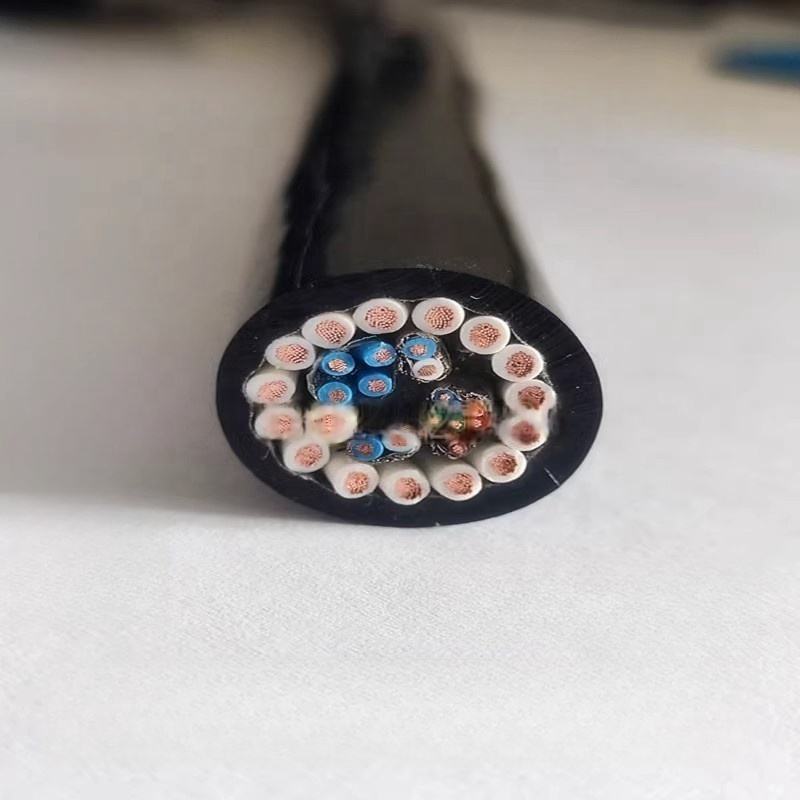

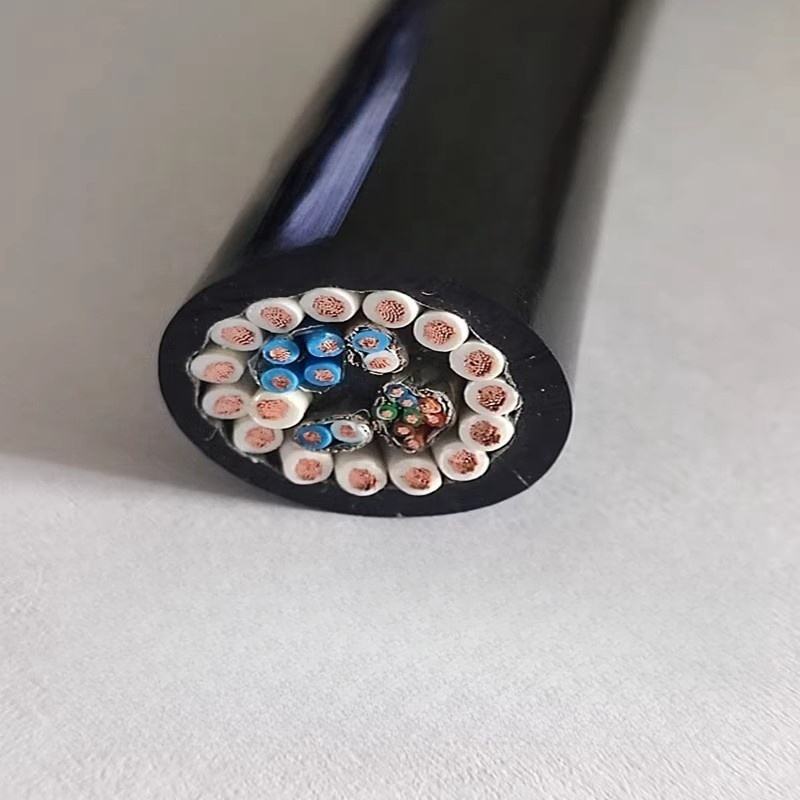

4/6/8/10/16‑Core Shielded Twisted Pair Network Cable + 2/3/4/5/6‑Core Power Integrated High‑Flex Drag Chain Cable

.High‑flex multi‑core shielded twisted pair network and power cable for industrial drag chain use.

.Combines 4–16 data pairs and 2–6 power cores in a single rugged jacket.

.Shielded pairs improve signal quality and reduce interference.

.Suitable for automation, robotics, control panels and dynamic installations.

.Custom configurations and OEM/ODM support available from Shanghai Rousheng Cable Co., Ltd.

A versatile high‑flex industrial cable combining shielded twisted pair network cores with integrated power conductors in a single robust assembly. Designed for drag chain systems, automated machinery, robotics, conveyor lines, and control applications, this cable offers dependable signal and power transmission in environments with repeated motion. The multi‑core structure simplifies wiring, reduces installation complexity, and improves maintenance efficiency.

Shanghai Rousheng Wire & Cable Co., Ltd. specializes in the development, production, and global supply of high‑flex drag chain cables and specialty cables across 100+ product families, delivering customized solutions for OEM/ODM applications worldwide.

Dual Function: Data + Power in One Cable

This cable integrates:

-

Shielded twisted pair network cores (4/6/8/10/16 cores) for reliable data and communication signals, minimizing electromagnetic interference (EMI).

-

Power cores (2/3/4/5/6 cores) for direct supply to motors, sensors or control devices.

Combining these in a single jacket simplifies installation and removes the need for separate power and network pathways.

High Flexibility for Drag Chain Use

The cable’s construction supports repeated bending and movement within drag chain systems. Shielded pairs maintain signal integrity even with continuous flexing, while the power cores support stable current delivery. Drag chain applications (e.g., CNC machines or robotic arms) benefit from this integrated design with reduced cable wear and improved machine uptime.

Enhanced Shielding & Signal Integrity

Individual twisted pairs with shielding help protect against noise and crosstalk — an important factor in industrial environments where motors and switching gear generate interference.

Key Features

-

Multi‑Core Design

Combines multiple shielded network pairs with power cores for complete signal and power routing in one cable. -

Shielded Twisted Pair (STP)

Improves EMI resistance and preserves high‑quality data transmission in electrically noisy industrial environments. -

High Flexibility

Suitable for drag chain and moving parts, reducing mechanical stress and extending service life. -

Robust Protection

Durable PVC jacket resists abrasion, oil, chemicals and physical wear. -

OEM/ODM Customization

Supports tailored core counts, conductor sizes, insulation types and jacket colours.

Typical Applications

-

Automated manufacturing lines

-

Industrial robots and multi‑axis systems

-

Control cabinets and panel wiring

-

Power and communication routing in machine tools

-

Conveyors and logistics equipment

-

Sensor and instrumentation networks

Product Construction & Materials

| Component | Description |

|---|---|

| Conductors | Fine multi‑strand copper (network and power cores) |

| Shielding | Foil and/or braided shielding around twisted pairs |

| Insulation | TPE (Thermoplastic Elastomer) for flexibility and thermal resistance |

| Sheath | Rugged PVC outer jacket |

| Core Options | 4–16 shielded network + 2–6 power cores (configurable) |

Mechanical Features

-

Drag Chain Flexibility: engineered for repeated motion with low bending fatigue

-

Shielded Pairs: strong protection from external interference

-

Colour‑coded Cores: simplifies identification and termination during installation

Technical Specifications (Typical)

| Attribute | Specification |

|---|---|

| Conductor Material | Multi‑strand Copper |

| Insulation Material | TPE (flexible) |

| Sheath Material | PVC (standard) |

| Core Configuration | 4/6/8/10/16 twisted pairs + 2/3/4/5/6 power cores |

| Voltage Rating | Standard industrial low voltage |

| Shield Type | Foil + braided shield (as required) |

| Temperature Range | Typical ‑20°C to +80°C |

| Flex Life | Designed for drag chain motion |

| OEM/ODM Options | Core counts, conductor gauge, insulation/jacket materials |

Frequently Asked Questions (FAQ)

Q1: What is the advantage of integrated network + power cable?

A1: Combining signal and power in one cable reduces wiring complexity, installation time, and potential points of failure compared to separate runs.

Q2: Why use shielded twisted pairs in this cable?

A2: Shielding reduces electromagnetic interference and maintains stable communication performance, especially in industrial environments with motors and high‑frequency switching.

Q3: Is this cable suitable for drag chain motion?

A3: Yes — the cable is engineered for repeated bending and movement within drag chain systems, improving durability and service life.

Q4: Can this cable be customized?

A4: Absolutely. Core counts, conductor material, insulation/jacket types, and lengths can be tailored to meet specific project requirements.

Q5: What environments is this cable best suited for?

A5: Ideal for industrial automation, robotics, conveyors, machine tools and other applications needing combined power and network routing.