How to Choose ROV Cables for Deep-Sea Operations

In the demanding world of deep-sea exploration, Remotely Operated Vehicles (ROVs) play a vital role across offshore oil and gas, marine science, subsea construction, renewable energy, and search-and-recovery missions. These unmanned underwater systems operate in some of the harshest environments on Earth—often at depths exceeding 6,000 meters.

At the heart of every successful ROV deployment lies a critical component: the ROV cable, commonly referred to as the umbilical cable or tether. This cable is far more than a physical connection—it is the ROV’s lifeline, delivering power, transmitting high-bandwidth data and video, and carrying precise control signals between the vehicle and the surface vessel.

Choosing the right ROV cable for deep-sea operations is not simply a matter of matching specifications. It directly affects mission reliability, operational safety, data quality, and total lifecycle cost. A poorly selected cable can result in signal loss, mechanical failure, or complete mission abort under extreme hydrostatic pressure.

In this comprehensive guide, we combine ROV cable selection principles with underwater and fiber optic cable performance insights to help you make informed, future-proof decisions.

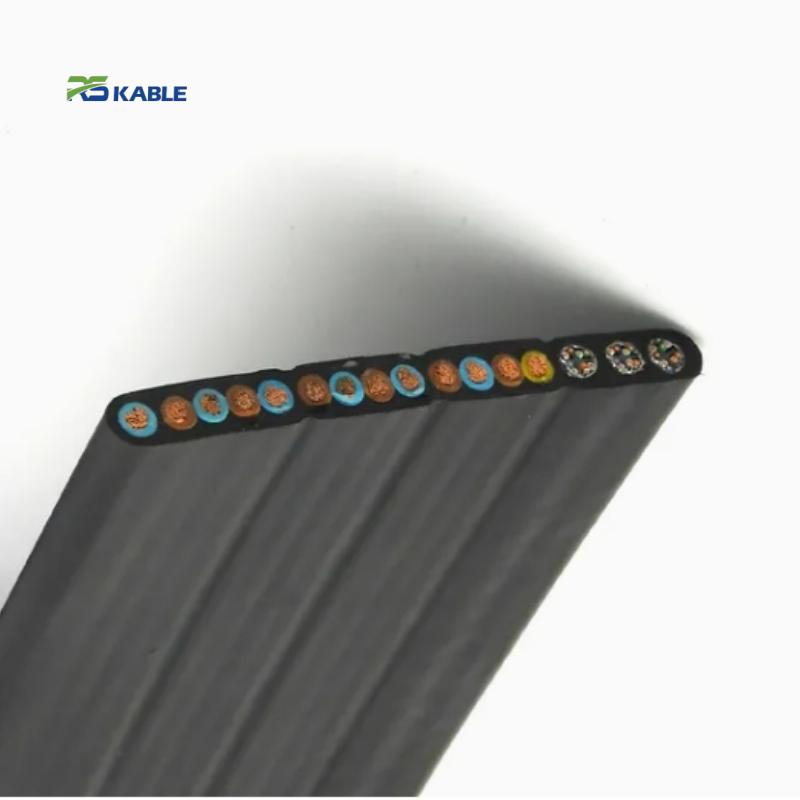

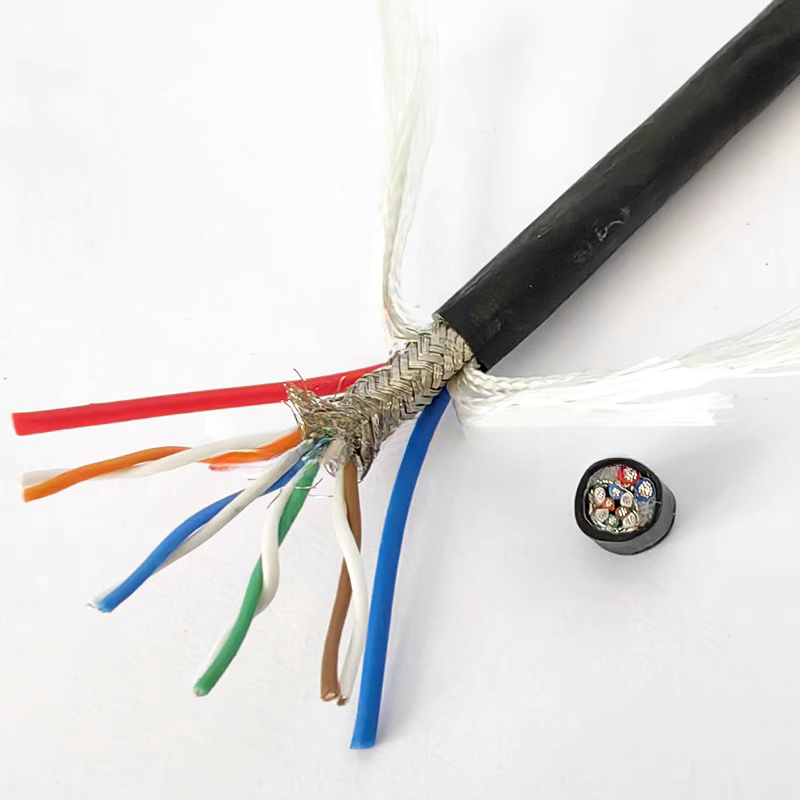

Neutral Buoyancy 2-4-6-8 Core Underwater ROV Cable – 24AWG & 26AWG Power & Signal Tether

This neutrally buoyant underwater ROV tether cable integrates multiple cores (2, 4, 6, or 8) with 24AWG and 26AWG conductors, engineered for reliable power and signal transmission in marine and subsea robotic applications. Designed for smooth drag, excellent flexibility, and stable communication underwater, this tether cable is suitable for remotely operated vehicles and subsea instrumentation systems. Neutral buoyancy construction minimizes drag and reduces load on ROV deployment systems. :contentReference

What Are ROV Cables and Why Are They Critical?

ROV cables are specialized electro-optical composite underwater cables designed to connect a remotely operated vehicle to its topside control system. Unlike standard underwater power or data cables, ROV umbilicals must perform multiple functions simultaneously:

-

Transmit electrical power to thrusters, manipulators, and tools

-

Carry high-speed data for real-time video, sonar, and sensor feedback

-

Deliver control signals for precise navigation and task execution

In deep-sea environments, cables are exposed to:

-

Extreme hydrostatic pressure (up to 1,000 atmospheres)

-

Near-freezing temperatures

-

Corrosive saltwater

-

Continuous dynamic motion (bending, twisting, tension)

Modern ROV cables increasingly integrate fiber optic underwater cable elements, enabling low-latency, high-bandwidth transmission for HD and 4K video, advanced telemetry, and complex sensor arrays.

Industry studies consistently show that cable-related issues are one of the leading causes of ROV downtime. Selecting the right cable can extend service life to 10–20 years with proper design and maintenance.

Key Factors to Consider When Selecting ROV Cables

Choosing an ROV cable is a multidisciplinary engineering decision. The following factors are critical for deep-sea applications.

1. Buoyancy: Neutral, Positive, or Negative?

Buoyancy control is one of the most important design considerations.

-

Neutral buoyancy cables are the industry standard for deep-sea ROVs. They neither sink nor float, minimizing drag, reducing tension on the vehicle, and improving maneuverability.

Neutral buoyancy is typically achieved using foamed polyethylene or syntactic materials combined with aramid fibers (Kevlar®). -

Positive buoyancy cables float slightly and are more common in shallow-water or special-purpose applications.

-

Negative buoyancy cables sink and are sometimes used in heavy work-class ROVs where stability in strong currents is required.

For operations below 2,000 meters, neutral buoyancy is almost always preferred to optimize vehicle performance and reduce energy consumption.

2. Tensile Strength and Mechanical Durability

Deep-sea ROV cables experience high tensile loads during deployment, recovery, and operation in currents.

Key indicators include:

-

Breaking strength: commonly 10,000–50,000 kg, depending on ROV class

-

Reinforcement layers: aramid fibers (Kevlar, Vectran) for high strength-to-weight ratio

-

Optional steel armoring: used in high-risk environments requiring additional abrasion or cut resistance

A cable with insufficient tensile capacity risks catastrophic failure, particularly during emergency recovery.

3. Data Transmission and Fiber Optic Integration

Modern ROV missions depend heavily on data quality.

-

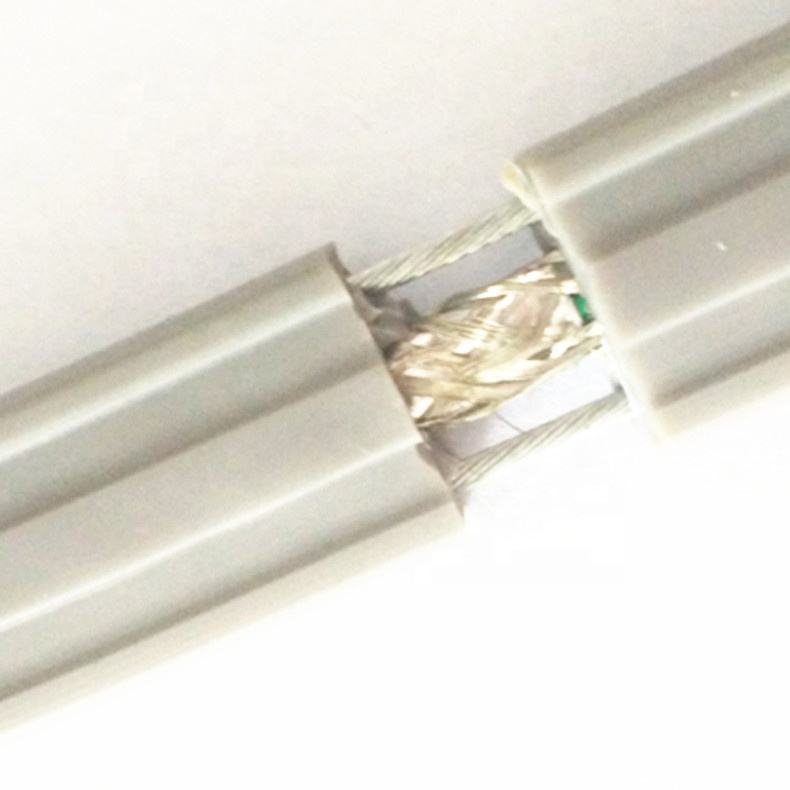

Fiber optic cables underwater offer unmatched bandwidth, low attenuation, and immunity to electromagnetic interference.

-

Single-mode fibers are preferred for long-distance, deep-sea transmission.

-

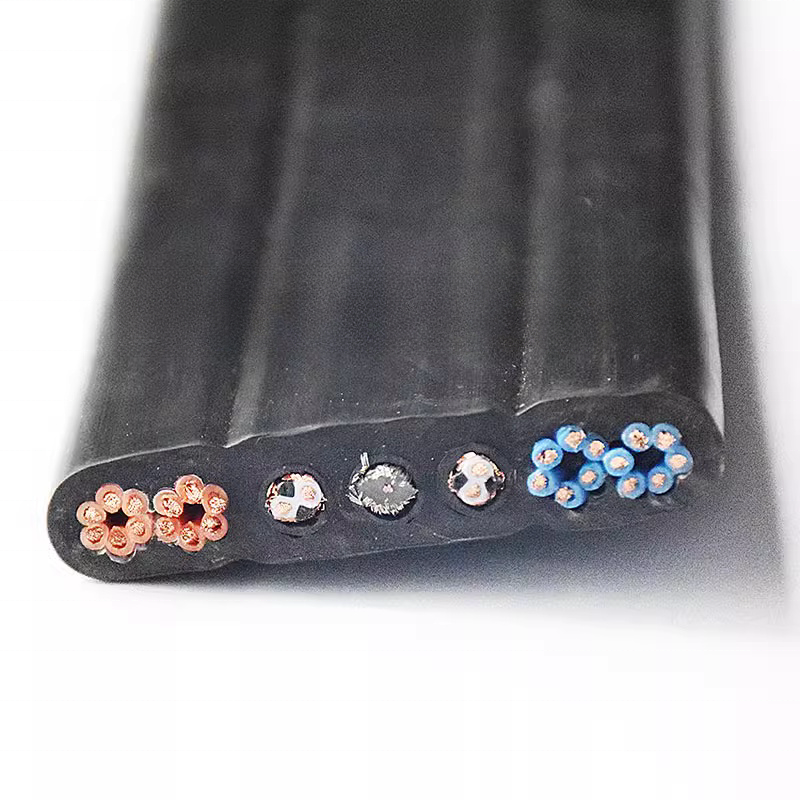

Hybrid electro-optical ROV cables combine copper power conductors, fiber optics, and coaxial elements in a single structure.

For applications involving HD, 4K, or 8K video, multi-beam sonar, or AI-assisted analysis, cables with 2–12 fiber cores (or more) are increasingly common.

4. Power Delivery Requirements

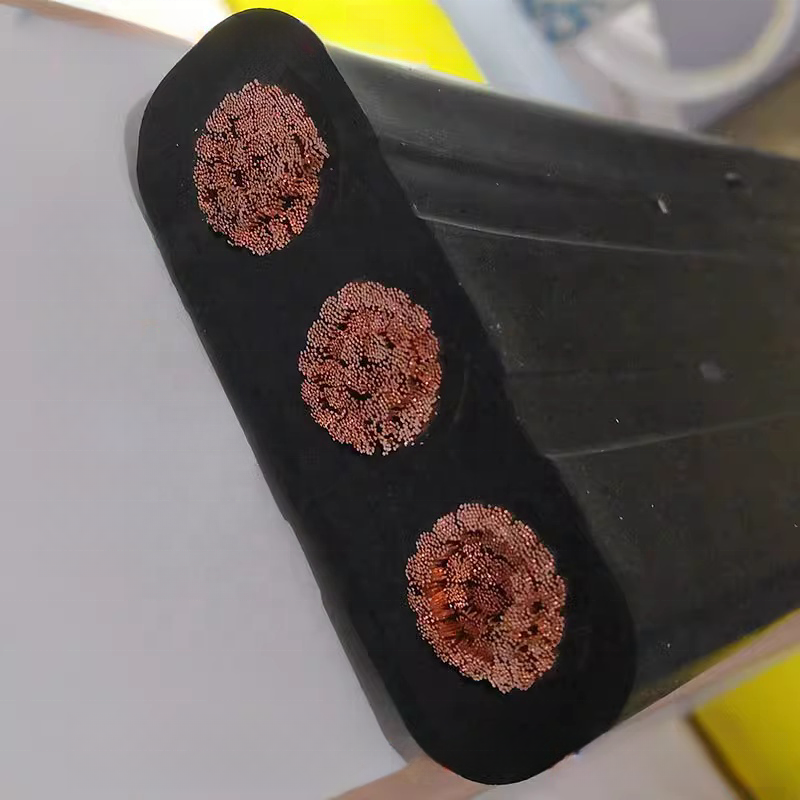

Reliable power transmission is essential for ROV propulsion and tooling.

-

Copper conductor sizing must account for voltage drop over long distances (often several kilometers).

-

High-voltage designs (1–6 kV) are used for heavy work-class ROVs to reduce current and conductor size.

-

Insulation materials such as EPR or XLPE ensure electrical stability under pressure.

Power requirements vary significantly between observation-class ROVs and heavy work-class ROVs, making system-level planning essential.

5. Environmental Resistance and Jacket Materials

Deep-sea cables must withstand extreme environmental stress:

-

Hydrostatic pressure exceeding 10,000 psi

-

Long-term seawater immersion

-

Oil, chemicals, and hydraulic fluids

-

Abrasion against seabed structures

Common outer jacket materials include:

-

Polyurethane (TPU) – excellent abrasion resistance and flexibility

-

Polyethylene (PE) – strong chemical and water resistance

-

Special elastomers for extreme temperature ranges

High-quality underwater cables often comply with IEC, IEEE, API, or ISO standards for subsea use.

6. Flexibility, Bend Radius, and Weight

Dynamic performance is just as important as static strength.

-

Minimum bend radius is typically 10–20× cable diameter

-

High flexibility reduces internal fatigue and fiber damage

-

Lightweight designs reduce load on winches and handling systems

Typical deep-sea ROV cable diameters range from 20 to 50 mm, depending on configuration.

7. Length and Customization

Standard ROV cable lengths range from 2,000 to over 10,000 meters, but many projects require custom designs.

Customization options include:

-

Fiber count and type

-

Power conductor size

-

Buoyancy tuning

-

Armoring structure

-

Compatibility with specific ROV platforms

Custom-designed umbilicals consistently outperform generic solutions in deep-sea environments.

Types of ROV Cables for Deep-Sea Applications

Common configurations include:

-

Neutral Buoyancy ROV Umbilicals – optimized for deep water

-

Electro-Optical Composite Cables – power + fiber optics + control

-

Armored ROV Cables – added protection for harsh environments

-

Lightweight Tethers – for observation-class ROVs

-

Heavy-Duty Work-Class Umbilicals – for construction and intervention tasks

Testing Standards and Quality Assurance

High-quality ROV cables undergo rigorous testing, including:

-

Cyclic bending and torsion tests

-

Tensile and crush resistance

-

Hyperbaric pressure testing

-

Long-term seawater immersion

Standards such as IEC 60228, IEEE 1580, NEK 606, and offshore oil & gas specifications are commonly referenced.

Common Mistakes to Avoid

-

Underestimating operating depth

-

Choosing cost over lifecycle reliability

-

Ignoring buoyancy optimization

-

Using insufficient fiber optic capacity

-

Relying on non-marine-grade industrial cables

These mistakes often result in higher downtime and replacement costs.

Maintenance Best Practices

-

Routine visual inspection of jackets

-

Proper spooling to avoid kinks

-

Scheduled electrical and optical testing

-

Controlled storage conditions

With proper care, high-quality ROV cables can exceed 10–20 years of service life.

The Future of ROV and Underwater Cable Technology

Emerging trends include:

-

Higher fiber density for data-intensive missions

-

Advanced composite reinforcement materials

-

Embedded sensors for real-time cable health monitoring

-

Environmentally friendly materials for sustainable subsea operations

Growth in offshore wind, deep-sea mining, and marine research continues to drive innovation.

FAQ

What is the difference between an ROV umbilical and a tether cable?

Umbilicals are primary, multi-function cables carrying power and data; tethers are usually lighter secondary lines.

How deep can ROV cables operate?

High-end designs exceed 10,000 meters, depending on system configuration.

Are fiber optic ROV cables necessary?

Yes, for deep-sea missions requiring HD video and high-speed data.

What does neutral buoyancy mean?

The cable has near-zero weight in water, reducing drag and improving control.

How long do ROV cables last?

Typically 10–20 years with proper design and maintenance.

Can ROV cables be repaired underwater?

In most cases, repairs are performed topside using splicing techniques.