How Long Do Underwater Cables Last?

Underwater cables—often referred to as submarine cables or subsea cables—quietly support much of modern life. They carry international internet traffic, transmit electricity from offshore energy projects, and enable deep-sea exploration and monitoring. Despite operating in one of the harshest environments on Earth, these cables are designed to function reliably for decades.

A common and reasonable question is: how long do underwater cables actually last?

There is no single number that applies to all cases. In practice, underwater cable lifespan depends on cable type, environment, mechanical stress, and how the system is managed over time. While a 25-year design life is often cited in the industry, real-world service life can be significantly shorter—or much longer.

This article explains what that lifespan really means, how different underwater cables age, and what determines whether a cable reaches the end of its life early or continues operating well beyond expectations.

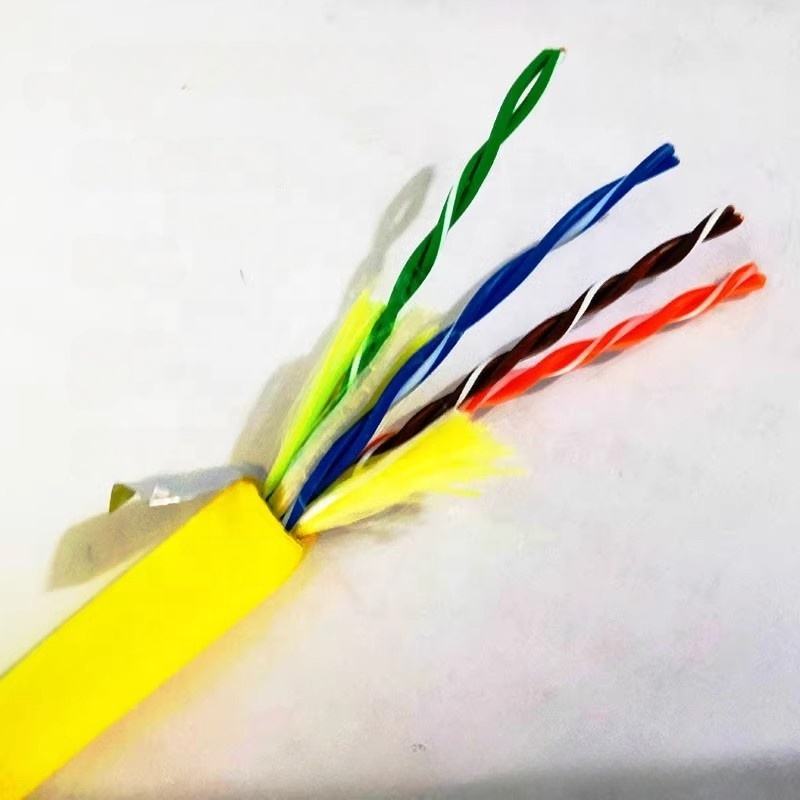

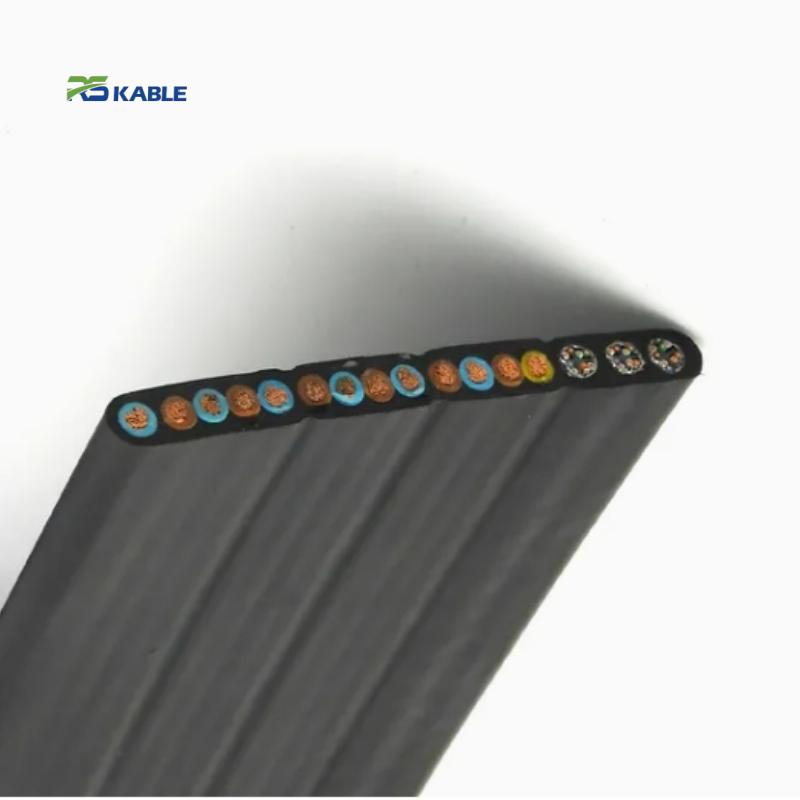

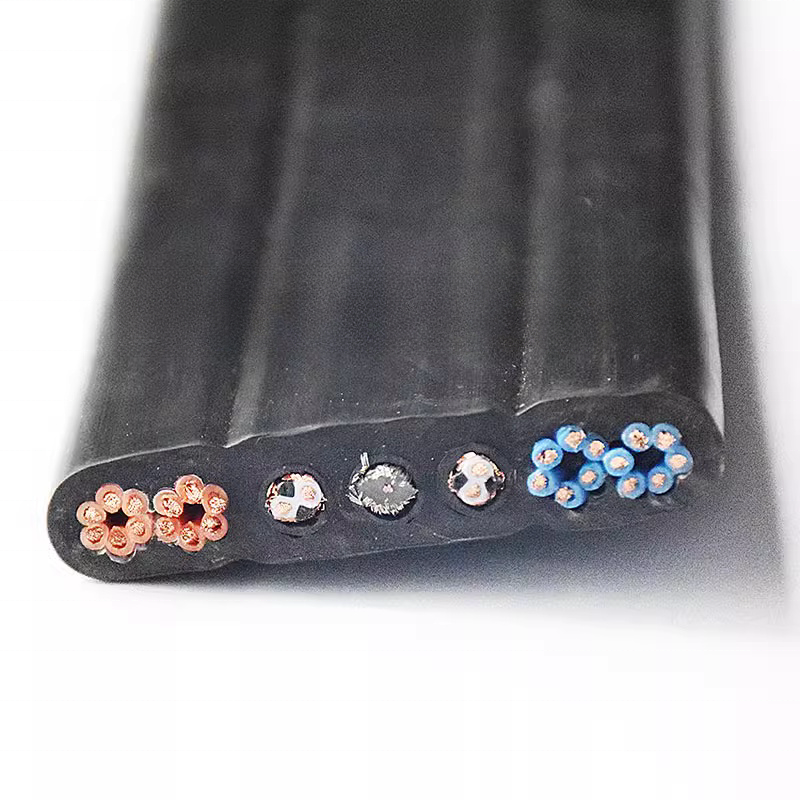

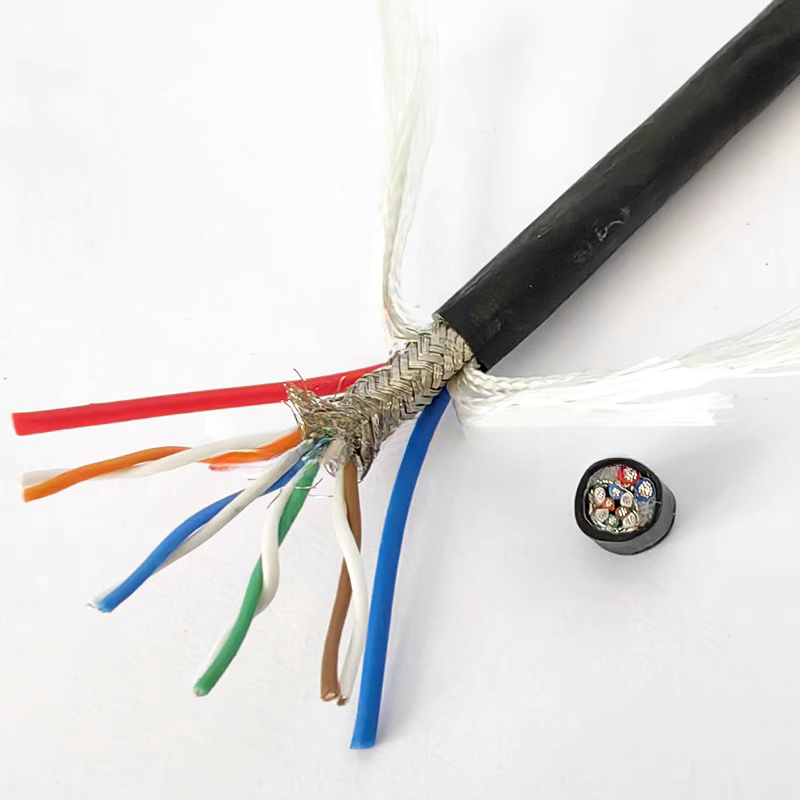

Custom Twisted Pair Anti-Seawater ROV Umbilical Cable – 2/4/6/8 Core | Underground & Subsea Robot Cable

High-performance custom twisted pair ROV umbilical cable designed for subsea and underwater robotic applications. Features anti-seawater corrosion resistance, flexible twisted pair cores in options of 2, 4, 6 or 8 cores, and rugged construction for reliable signal and power transmission in demanding subsea environments. Perfect for ROVs, underwater robots, and offshore cable systems.

The Meaning of “Design Life” in Underwater Cables

When manufacturers specify a design life—most commonly 25 years—they are defining a period during which the cable is expected to operate safely, predictably, and economically under normal conditions.

Design life does not mean:

-

the cable will fail after 25 years

-

the cable becomes unsafe at year 26

Instead, it reflects assumptions about material aging, risk exposure, and long-term operating cost. Many cables remain functional long after their nominal design life, especially when they are installed in stable environments and protected from external damage.

In fact, a large number of submarine cables are retired not because they fail, but because they no longer meet modern performance or capacity requirements.

Lifespan Differences by Cable Function

Underwater cables serve very different roles, and their longevity varies accordingly.

Submarine Fiber Optic Communication Cables

These are the cables most people think of first—the global network that carries international internet and data traffic.

-

Typical design life: ~25 years

-

Actual service life: often 25–40 years

Optical fibers themselves degrade very slowly. When installed in deep water, far from anchors and fishing activity, they experience minimal mechanical stress. As a result, physical failure is relatively rare.

However, many telecom cables are decommissioned earlier than their physical limits because newer systems can carry far more data using advanced fiber and modulation technologies. In other words, obsolescence often arrives before structural failure.

Subsea Power Cables

Power cables used for offshore wind farms, oil and gas fields, and island interconnectors are built to handle high electrical loads for long periods.

-

Typical lifespan: 30–40 years

These cables rely heavily on insulation performance. Materials such as XLPE are designed to resist electrical aging, moisture ingress, and thermal cycling. When load conditions remain within design limits and installation quality is high, subsea power cables often meet or exceed their intended lifespan.

Failures, when they occur, are more often related to mechanical damage near shore than internal electrical degradation.

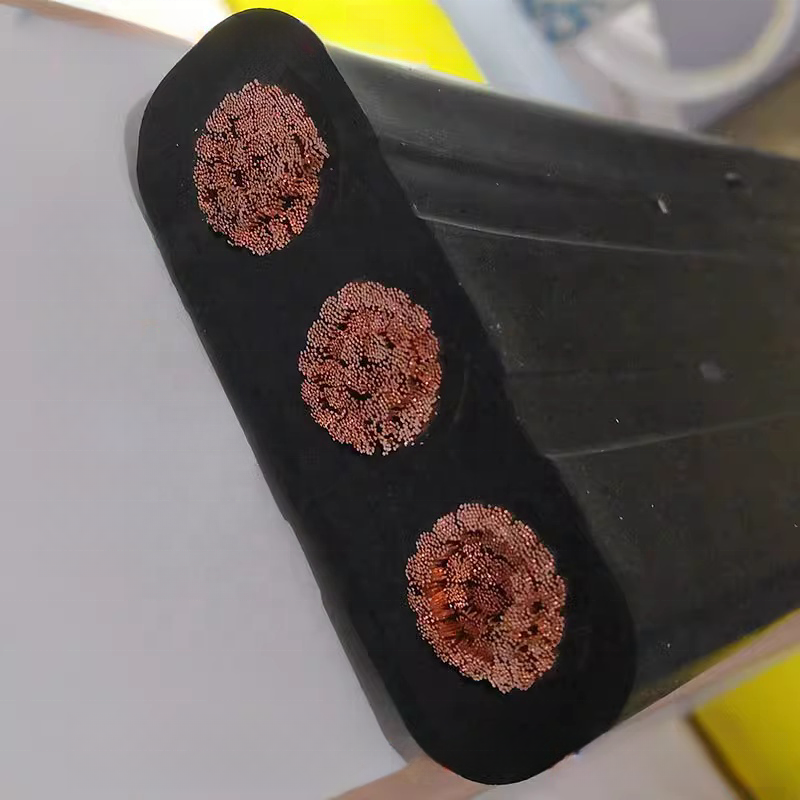

ROV Umbilical and Dynamic Cables

Cables used for remotely operated vehicles (ROVs) and other subsea tools live under very different conditions.

-

Typical lifespan: 5–15 years

These are dynamic systems that are constantly bent, tensioned, reeled, and deployed. Fatigue—not corrosion—is the dominant aging mechanism. For this reason, lifespan is often measured in operational cycles, not calendar years.

Design improvements such as neutral buoyancy, aramid reinforcement, and optimized bend radius help extend service life, but dynamic cables will always wear faster than static seabed systems.

Why Some Underwater Cables Last Longer Than Others

Several factors consistently determine how long an underwater cable remains in service.

Water Depth and Location

Depth plays a surprisingly important role.

-

Deep water: fewer human activities, stable seabed → longer lifespan

-

Shallow water: anchors, fishing gear, currents → higher failure risk

Statistically, most cable faults occur within a few hundred meters of the shoreline, not in the deep ocean.

Installation Quality

Careful route planning and controlled installation can add many years to a cable’s life. Avoiding rocky seabeds, steep slopes, and high-traffic zones reduces long-term mechanical stress.

Poor installation practices—excessive tension, improper burial, or inadequate protection—are among the most common causes of premature failure.

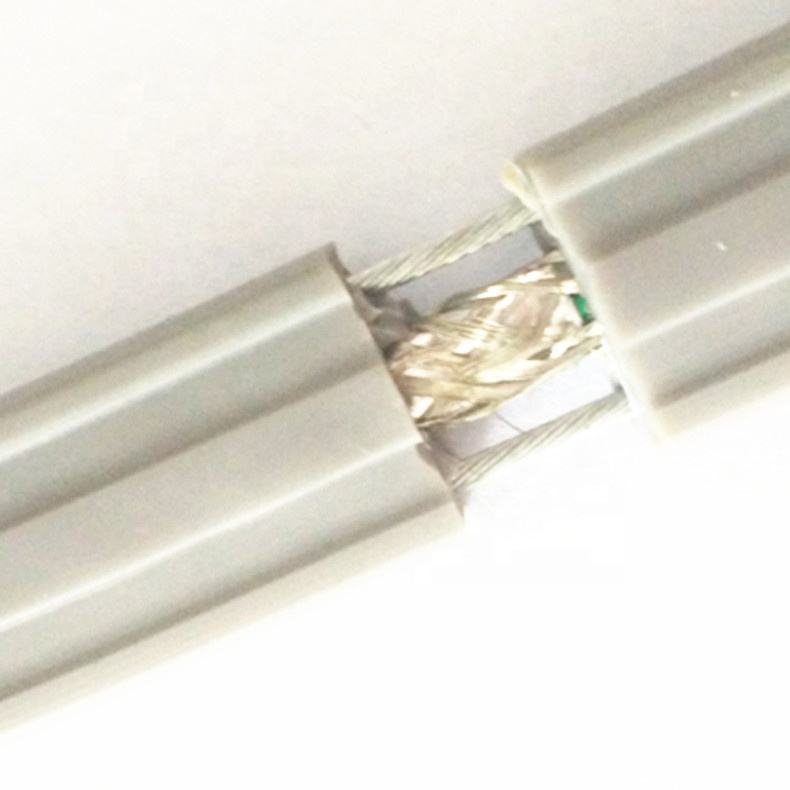

Mechanical Protection and Materials

Cable longevity depends heavily on:

-

armor design

-

outer jacket material

-

water-blocking systems

Well-matched protection to the operating environment is far more important than simply adding more armor. Overbuilt cables can introduce stiffness and fatigue issues, while under-protected cables fail early.

Human Activity

Across the industry, human interference remains the leading cause of damage. Fishing trawls and anchors account for the majority of reported faults worldwide.

This reality explains why nearshore cable sections are typically buried or heavily armored, even though the cable itself may be capable of lasting decades.

Maintenance and Repair: Extending Real Service Life

Underwater cables are not “install and forget” systems. Continuous monitoring plays a major role in extending lifespan.

For telecom cables, changes in signal performance often reveal developing issues long before failure occurs. Power cables are monitored for insulation health and thermal behavior.

When damage happens, specialized repair vessels retrieve the affected section, splice in new cable, and redeploy it. These interventions often restore full functionality and allow the remaining cable to continue operating for many additional years.

Lessons from Real-World Cable History

History shows how dramatically underwater cable longevity has improved.

Early submarine cables in the 19th century failed within months due to inadequate insulation. By contrast, fiber optic systems installed in the late 1980s and 1990s routinely operated for two decades or more.

Modern systems benefit from better materials, improved seabed mapping, and decades of operational experience. As a result, unexpected early failures are now the exception rather than the norm.

Will Future Underwater Cables Last Longer?

Current trends suggest yes.

New developments include:

-

enhanced polymer jackets with improved aging resistance

-

integrated sensing for early fault detection

-

better fatigue modeling for dynamic cables

-

more resilient routing strategies

Rather than radically increasing design life numbers, the industry focus is shifting toward predictability and risk reduction, ensuring cables reliably meet or exceed their intended service period.

So, how long do underwater cables last?

In most cases:

-

Telecom cables: around 25 years, often longer

-

Power cables: commonly 30–40 years

-

Dynamic ROV cables: significantly shorter due to mechanical fatigue

The true lifespan of an underwater cable is shaped less by time alone and more by environment, design choices, and how the system is operated and protected.

As global dependence on subsea infrastructure continues to grow, longevity is no longer just a technical question—it is a strategic one. Understanding what limits cable life is essential for building reliable, long-term underwater systems.

FAQ

Do underwater cables stop working after 25 years?

No. Many continue operating well beyond their design life.

Why are some cables replaced early?

Most often due to capacity upgrades, not physical failure.

Which underwater cables last the longest?

Deep-water fiber optic cables with minimal human exposure.

Why do ROV cables wear out faster?

They experience constant bending, tension, and handling.

Can repairs significantly extend cable life?

Yes. Proper repairs often add many years of service.