Fiber Optic Underwater Cable: Structure and Performance

Fiber optic underwater cables are a critical component of modern subsea communication and data transmission systems. From global internet infrastructure and offshore energy platforms to marine research and remotely operated vehicle (ROV) operations, these cables enable reliable, high-speed data transfer in some of the most challenging environments on Earth.

Unlike conventional land-based fiber optic cables, fiber optic underwater cables are specifically engineered to operate in submerged conditions where high pressure, saltwater corrosion, mechanical stress, and long-term environmental exposure are constant factors. Understanding how these cables are structured and how they perform underwater is essential for engineers, system designers, and project planners working in marine and offshore industries.

This article provides an in-depth explanation of fiber optic underwater cable structure and performance, including materials, mechanical design, environmental resistance, applications, and long-term reliability.

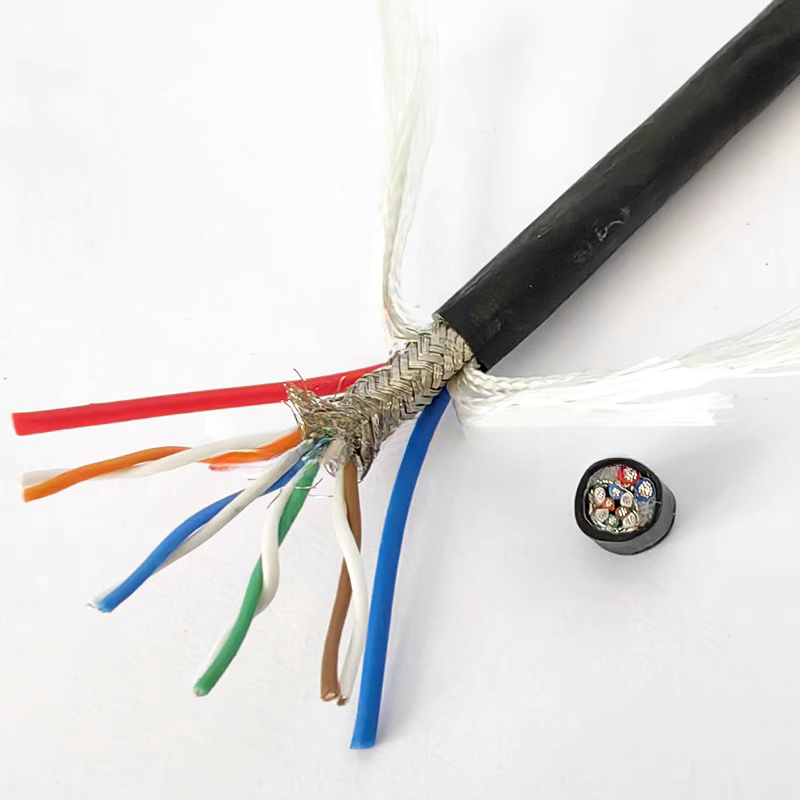

High Flexibility Bend Resistant PUR Drag Chain Single Core Cable (OEM)

This high-flexibility single core cable is engineered for continuous dynamic movement in drag chains and industrial applications, featuring a robust PUR outer sheath with excellent abrasion, oil, and chemical resistance and designed to withstand frequent bending cycles in automated systems and machinery.:contentReference

What Is a Fiber Optic Underwater Cable?

A fiber optic underwater cable is a specialized cable designed to transmit data using optical fibers while operating reliably underwater. These cables are installed in oceans, seas, lakes, rivers, and offshore environments where conventional cables would quickly fail.

They are commonly used for:

-

Subsea and offshore communication systems

-

Underwater data transmission

-

ROV and AUV control and monitoring

-

Offshore oil and gas platforms

-

Marine scientific research

-

Environmental monitoring and sensing networks

Depending on the application, underwater fiber optic cables may be deployed in shallow water, deep-sea environments, or dynamic underwater systems where continuous movement is involved.

Why Fiber Optics Are Used Underwater

Fiber optics have become the preferred technology for underwater data transmission due to several key advantages over traditional copper cables:

-

High bandwidth capacity for large data volumes

-

Low signal attenuation over long distances

-

Immunity to electromagnetic interference (EMI)

-

Lightweight structure compared to copper conductors

-

Long-term signal stability

These advantages make fiber optic cables underwater ideal for real-time video transmission, sensor data collection, and long-distance subsea communication.

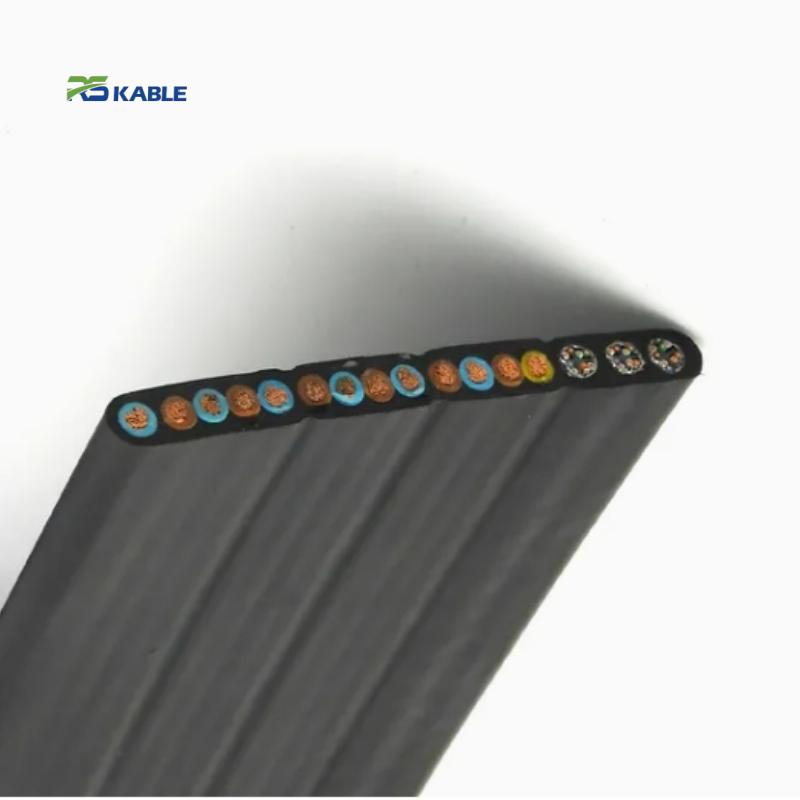

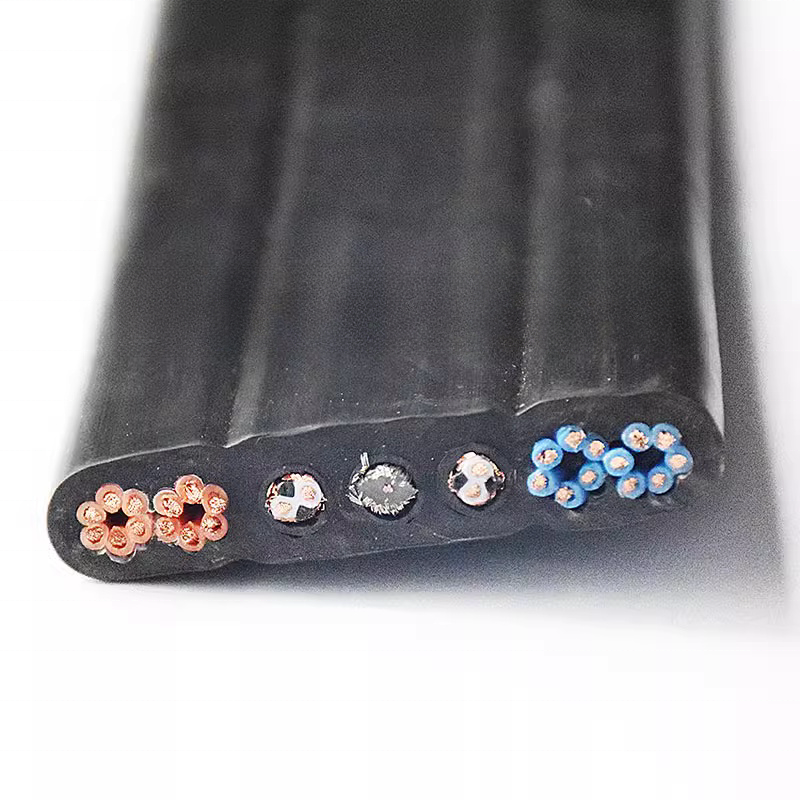

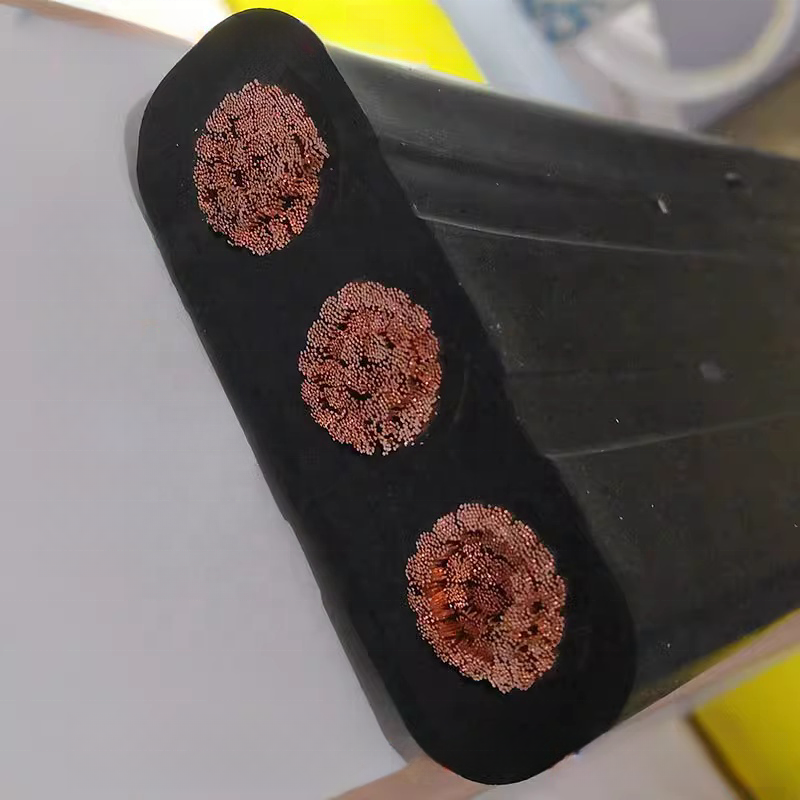

Basic Structure of a Fiber Optic Underwater Cable

The performance of an underwater fiber optic cable is determined by its multi-layer structure. While designs vary depending on water depth and application, most cables share a similar construction concept.

Optical Fiber Core

At the center of the cable is the optical fiber core, typically made of ultra-pure silica glass. This core is responsible for transmitting light signals that carry data.

Common fiber types include:

-

Single-mode fiber, used for long-distance and high-bandwidth transmission

-

Multi-mode fiber, used for shorter distances and localized underwater systems

The quality of the fiber core directly affects signal loss, bandwidth, and transmission distance.

Primary Coating and Buffer Layer

Surrounding the optical fiber is a protective coating and buffer layer. This layer serves multiple purposes:

-

Protects the fiber from mechanical stress

-

Prevents microbending and signal degradation

-

Provides initial moisture resistance

In underwater fiber optic cables, buffer materials are specially selected to maintain performance under pressure and temperature variations.

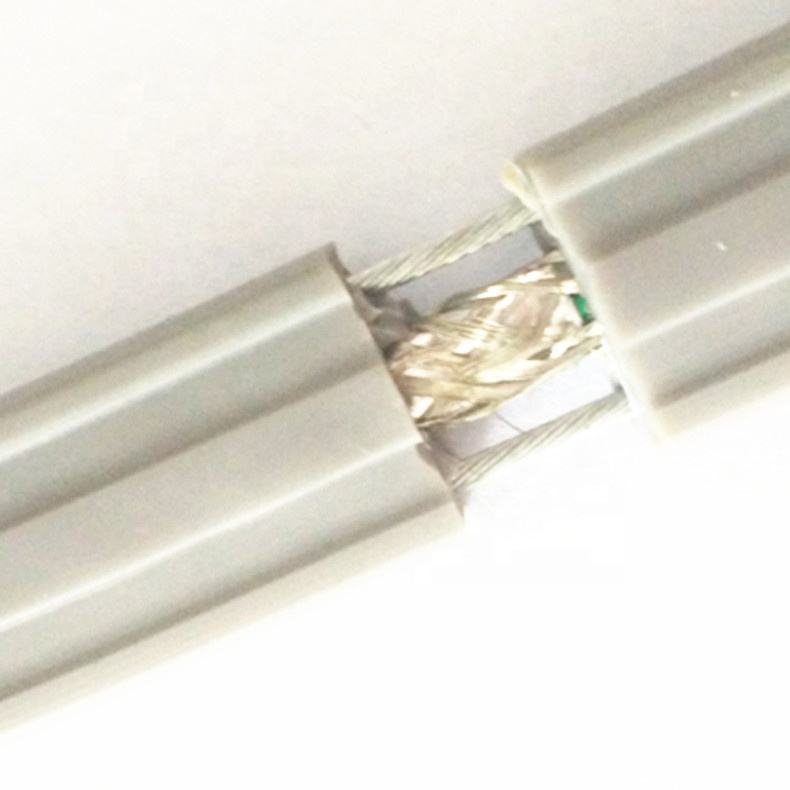

Strength Members

Underwater cables are exposed to high tensile forces during installation, deployment, and recovery. To protect the fiber, strength members are incorporated into the cable design.

Common strength members include:

-

Aramid yarn (Kevlar)

-

Steel wire strands

-

Fiber-reinforced plastic (FRP)

These elements absorb mechanical loads and prevent damage to the optical fibers during operation.

Water-Blocking Components

Water ingress is one of the biggest threats to underwater cable reliability. To address this, fiber optic underwater cables include water-blocking systems, such as:

-

Gel-filled cores

-

Water-swellable tapes

-

Water-blocking yarns

These materials prevent water from traveling along the cable if the outer jacket is damaged.

Armoring Layer

For subsea and deep-sea environments, an armoring layer is essential. Armored underwater fiber optic cables are designed to resist:

-

Seabed abrasion

-

Mechanical impact

-

Fishing activities and anchors

-

External pressure

Depending on the depth and environment, cables may feature single or double steel wire armor for added protection.

Outer Jacket

The outer jacket is the first line of defense against the marine environment. Common jacket materials include:

-

Polyurethane (TPU)

-

Polyethylene (PE)

-

Specialized marine-grade polymers

TPU jackets are widely used due to their flexibility, abrasion resistance, and long-term durability in saltwater environments.

Performance Characteristics of Fiber Optic Underwater Cables

Signal Transmission Performance

One of the most important performance advantages of fiber optic underwater cables is their ability to transmit data with minimal signal loss.

Key characteristics include:

-

High data bandwidth

-

Low insertion loss

-

Stable signal quality over long distances

Because optical fibers do not carry electrical signals, they are immune to electromagnetic interference, making them ideal for offshore and industrial environments.

Pressure Resistance

Water pressure increases significantly with depth. Fiber optic underwater cables are designed to maintain structural integrity under extreme pressure conditions.

Pressure-resistant designs ensure:

-

Optical fibers remain undistorted

-

Signal transmission remains stable

-

Long-term performance at depth

This is particularly important for deep-sea installations and offshore energy systems.

Mechanical Strength and Flexibility

Underwater fiber optic cables may be used in static or dynamic applications.

-

Static cables are installed on the seabed and remain stationary

-

Dynamic cables are subject to continuous movement, bending, and torsion

Dynamic applications, such as ROV tether systems, require cables with excellent flexibility and fatigue resistance.

Environmental Resistance

Marine environments are harsh and unpredictable. High-quality underwater fiber optic cables are designed to resist:

-

Saltwater corrosion

-

Oil and chemical exposure

-

Biological growth

-

Temperature fluctuations

These characteristics help reduce maintenance requirements and extend cable service life.

Longevity and Reliability

When properly designed, installed, and maintained, fiber optic underwater cables can operate reliably for 20 to 30 years or more. Long service life is achieved through:

-

Robust materials

-

Multi-layer protection

-

Strict quality control during manufacturing

Applications of Fiber Optic Underwater Cables

Subsea Communication Networks

Underwater fiber optic cables are the foundation of global subsea communication infrastructure, carrying vast amounts of data between continents and offshore facilities.

ROV and AUV Systems

ROV and AUV operations rely heavily on fiber optic underwater cables for:

-

Real-time video transmission

-

Sensor data exchange

-

Control and navigation signals

These cables often combine optical fibers with power conductors and strength members in a single composite design.

Offshore Oil and Gas Platforms

In offshore environments, underwater fiber optic cables are used for:

-

Platform-to-platform communication

-

Subsea monitoring systems

-

Structural health monitoring

Their resistance to EMI makes them especially valuable in electrically noisy offshore settings.

Marine Research and Environmental Monitoring

Scientific institutions deploy underwater fiber optic cables to connect sensors and monitoring equipment used in:

-

Oceanographic research

-

Seismic monitoring

-

Long-term environmental observation

Factors That Affect Underwater Cable Performance

Several factors must be considered when selecting or designing a fiber optic underwater cable:

-

Water depth and pressure

-

Static or dynamic operation

-

Required data bandwidth

-

Mechanical load and tensile strength

-

Environmental exposure

-

Installation method

Matching cable design to actual operating conditions is essential for reliable long-term performance.

Fiber Optic Underwater Cable vs Copper Underwater Cable

Compared to copper-based underwater data cables, fiber optic solutions offer:

-

Higher data transmission capacity

-

Longer transmission distance

-

Lower signal loss

-

No electromagnetic interference

-

Reduced weight

These advantages have made fiber optics the dominant technology in modern underwater communication systems.

Future Trends in Underwater Fiber Optic Cable Technology

As offshore industries and marine robotics continue to evolve, underwater cable technology is advancing rapidly. Key trends include:

-

Higher fiber counts in compact designs

-

Hybrid cables combining power and data

-

Improved neutral buoyancy cable designs

-

Enhanced materials for extreme environments

-

Smart cables with integrated sensing capabilities

These innovations will further expand the role of fiber optic underwater cables in subsea systems.

Frequently Asked Questions About Fiber Optic Underwater Cables

What is a fiber optic underwater cable?

A fiber optic underwater cable is a specially designed cable that uses optical fibers to transmit data reliably in submerged and marine environments.

What are underwater fiber optic cables used for?

They are used for subsea communication, offshore platforms, ROV systems, marine research, and underwater monitoring applications.

How long do underwater fiber optic cables last?

Most underwater fiber optic cables are designed for a service life of 20–30 years, depending on environmental conditions and mechanical stress.

Are fiber optic underwater cables better than copper cables?

Yes. Fiber optic underwater cables offer higher bandwidth, longer transmission distances, and immunity to electromagnetic interference.

Can fiber optic cables work in deep-sea environments?

Yes. With proper armoring and pressure-resistant design, fiber optic underwater cables can operate reliably at extreme ocean depths.